The Critical Role of Thermal Management

As extruded material solidifies, it undergoes a critical thermal transition. Uncontrolled cooling can introduce internal stresses, warping, and dimensional inaccuracies, compromising part integrity even more in large-format parts. Conversely, a managed cooling process allows for uniform material crystallization, enhancing mechanical properties, and maximizing part longevity.

Factors Influencing Thermal Behavior

Several variables influence the cooling process:

- Material Composition: Each polymer possesses unique thermal expansion coefficients and cooling rates. High-performance polymers like PEEK, PEI, and ULTEM demand precise thermal management due to their susceptibility to warping.

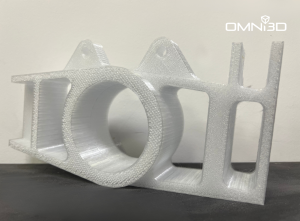

- Part Geometry: Complex geometries with intricate details or large overhangs require careful consideration to prevent heat-induced distortions.

- Build Volume: Larger parts necessitate extended cooling times to dissipate heat evenly.

- Ambient Conditions: Temperature and humidity fluctuations in the printing environment can impact the cooling process.

- Build Enclosure: Precisely heated chambers are a must to maintain and control a stable thermal environment, minimizing part distortion.

Optimizing the Cooling Process

To mitigate thermal challenges and produce high-quality parts, consider these best practices:

- Active Cooling Systems: Omni3D feature Explore options like fans or chilled water circulation to accelerate cooling while maintaining control.

- Post-Processing Considerations: For critical applications, consider annealing or heat treatment to further refine part properties.

- Material and Process Optimization: Continuously evaluate material selection and printing parameters to achieve desired thermal behavior.

By mastering the art of thermal management, you can unlock the full potential of your large-format industrial 3D printer, producing parts that meet the stringent demands of industries such as aerospace, automotive, and energy.

Remember: A well-controlled cooling process is the cornerstone of producing high-quality, functional parts in large-format 3D printing.