Resources

Insights, trends, and actionable strategies for aerospace, automotive, industrial maintenance, and defense industries using cutting-edge large-format 3D printers.

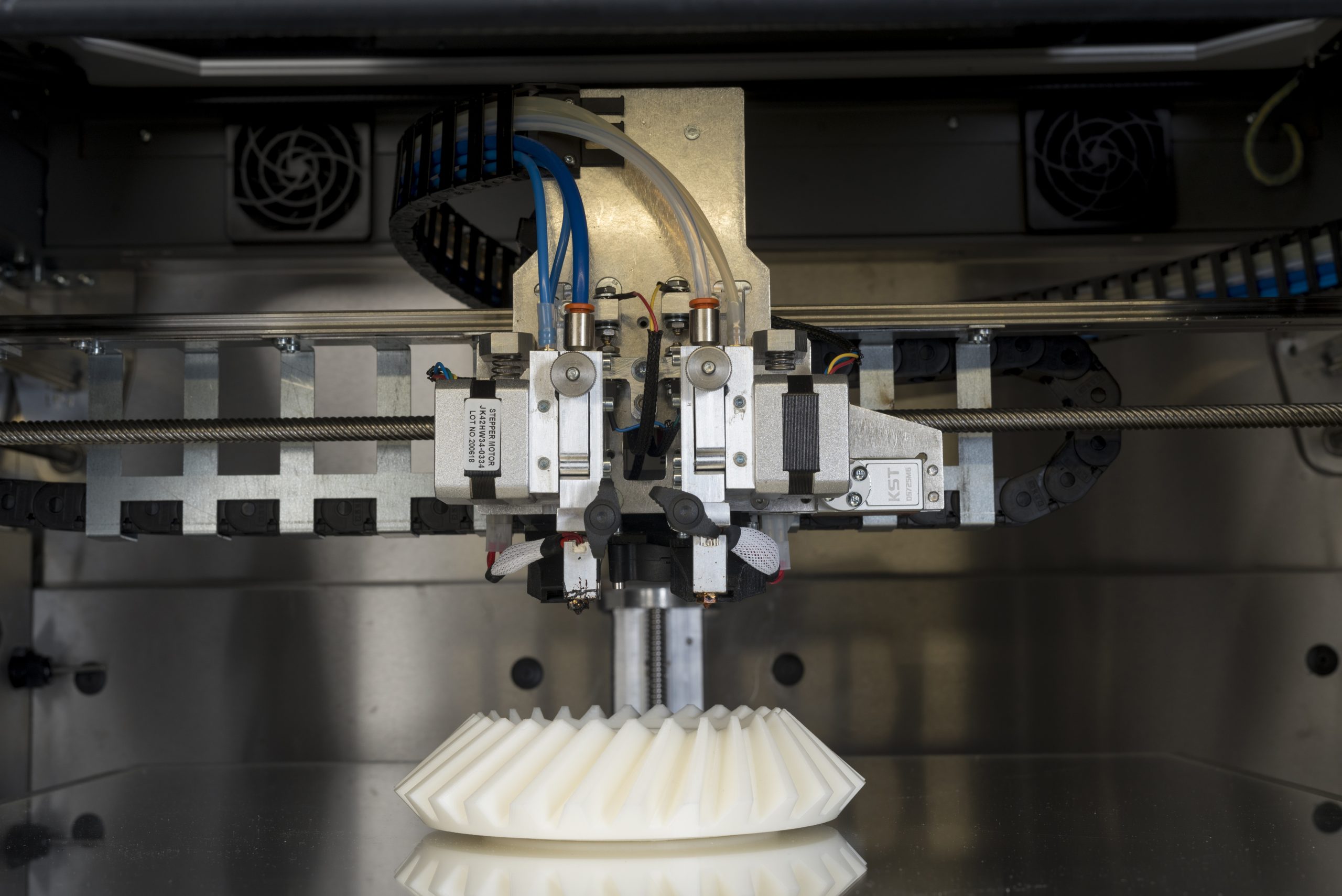

Application of 3D printing in maintenance

The 3D printing technology gives a wide range of possibilities to produce elements, spare parts and tools used in the maintenance area. 3D printers can make even the most non-standard and difficult to access elements in a short time, thus saving time and production costs.

Automotive: Durable spare parts printed on an industrial 3D printer

The possibilities offered by 3D printing technology have been used for a long time in the automotive industry and at every stage of production - from prototyping to the production of ...

Automotive: Durable spare parts printed on an industrial 3D printer

The possibilities offered by 3D printing technology have been used for a long time in the automotive industry and at every stage of production - from prototyping to the production of spare parts and final elements. The available materials allow us to print not only lightweight but also extremely durable elements.

BioElectroCathode project – biofuels thanks to 3D printer

BioElectroCathode is an innovative project that aims to apply 3D printing technology to the production of electrochemical bioreactors. Together with Scientists – Omni3D’ team is involved in developing the way to produce cathodes necessary for the bioelectrosynthesis process. The solution is to find a way to convert CO2 from exhaust and the air into biogas that can be used as a fuel. How 3D printing technology from Omni3D can help in production of “the fuels of the future”?

Can metal components be replaced with 3D printed CF?

3D printing technology gives us the advantage of cost reduction and makes the production time shorter. The 3D printing materials that are available on the market create the possibility to replace even the hardest components on the production lines. So it's no surprise that it's possible to replace metal parts with 3D printing. Today, we will answer the question: why You should choose 3D printing?

Chamber Temperature’s Impact on Strength in material extrusion

Achieving optimal part quality in additive manufacturing material extrusion often hinges on factors beyond mere geometry and material selection. One such critical aspect is the controlled thermal environment provided by heated chambers, particularly when working with advanced materials like super polymers.

Cheaper and faster low-volume production

An automotive manufacturing company approached Omni3D with a request to print a custom part of a police car body component.

The main goal was to finalize the project quickly while staying on ...

Chemical resistant 3D printer filaments

The more we delve into the world of filaments and the possibility of their use in various industries and sectors, the more often we think about chemical "durability". The field of research in this aspect is not yet developed - and some experiments are burdened with a long term of feasibility. What does it mean?

Door end cap – 3D printing in Architecture

A few years ago, the furniture industry discovered the benefits of 3D service. Designers and architects look for inspiration and opportunities to experiment with materials, structures and shapes in this technology. The presented designs confirm the potential of 3D printing in interior design i.e. original furniture, sophisticated lamps, personalized vases and other everyday equipment to satisfy every customer.

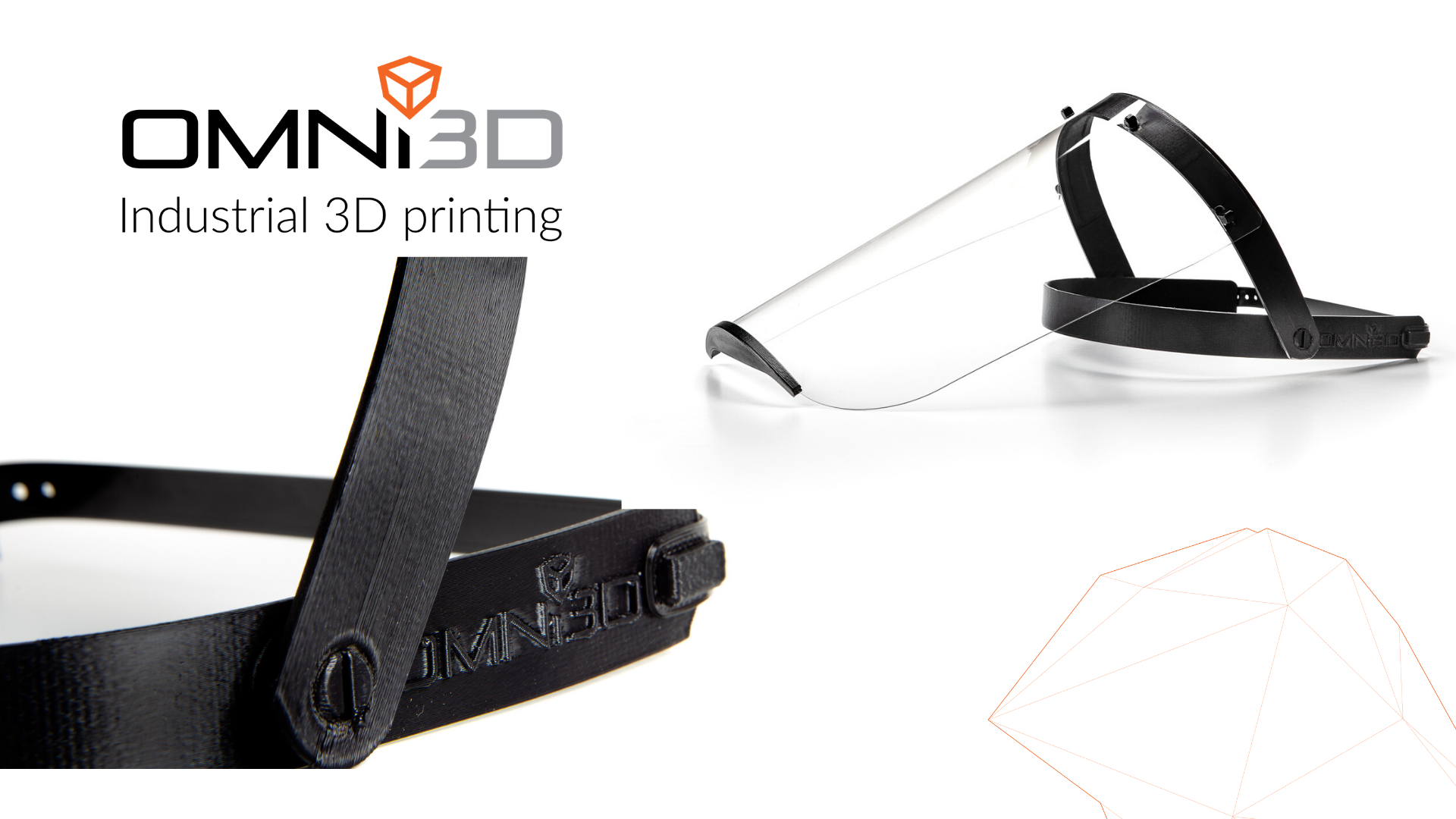

Face shields project from Omni3D

Designed in cooperation with doctors, the improved face shields provides high wearing comfort thanks to the adjustable and lifted visor. Thanks to the use of high quality materials, it can be disinfected entirely with standard agents.

No results found.

Trusted by