Resources

Insights, trends, and actionable strategies for aerospace, automotive, industrial maintenance, and defense industries using cutting-edge large-format 3D printers.

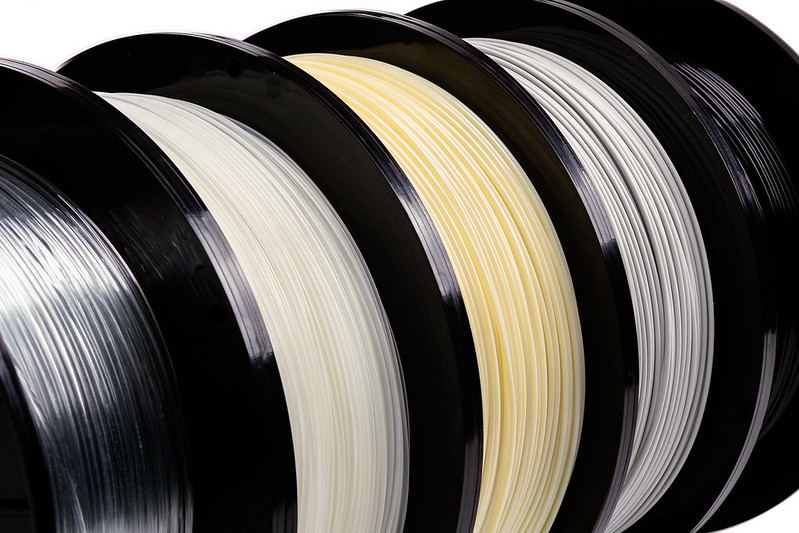

Omni3D extending the filament offer

Antistatic properties, increased temperature, chemical and mechanical resistance – these are just some of the features of the new Omni3D filaments, which will soon be introduced to the offer.

Omni3D has received the ISO 9001: 2015 certificate. What changes await the company and customers?

For Omni3D, quality has always been a priority. As a start-up, we have taken many steps to achieve this goal. It has now been formally sealed. On May 4, under number 487345, the ISO 9001: 2015 certificate was issued for Omni3D. The successful completion of the certification audit confirms the compliance of our services and products as a manufacturer of 3D printers with the international standard specifying the requirements for quality management.

Omni3D virtual showroom

The pandemic has forced many companies to transfer sales and communication with customers to the virtual world of the Internet. Year of 2020 forced a lot of enterprenaurs to focus on creativity and marketing activities that would allow for uninterrupted contact with customers at this exceptional time. In response to these needs, Omni3D provides a virtual showroom inviting customers to the world of 3D printing

Omni500 LITE printer – economical solution from Omni3D

Management by a dedicated website, two extruders with a material presence sensor, a working area enabling printing of large elements – these are only selected functions of the Omni500 LITE printer by Omni3D. Most importantly, its high quality is also followed by an attractive price – this is important information for those who value economic solutions.

On-Demand Parts for Legacy Armor: Maintaining BMP-1 Vehicles with Omni3D’s Large-Format Printing

Maintaining a fleet of BMP-1 infantry fighting vehicles—still deployed by several NATO militaries—presents major logistical hurdles. Designed in the Cold War era, these vehicles are still ...

Optimization of the production line thanks to the Omni3D printer

3D printing allows you to quickly check the accuracy of the dimensions before ordering an expensive form for the production of the tool. Thanks to the Omni3D printer, the customer could try out the designed tool and apply corrections before ordering the production of the final product.

Optimizing BOSCH Production efficiency with 3D Printing

Faced with the challenge of safely transporting sensitive electronic components, BOSCH sought a reliable, fast and efficient solution. By partnering with Omni3D, they were able to develop a ...

Optimizing Quality Assurance with Precise 3D Printed Fixtures

Meyra, a global leader in wheelchair manufacturing and rehabilitation equipment, has embraced 3D printing technology to enhance its quality control processes. Traditionally, the company relied ...

Pioneering Industrial Extrusion 3D Printing for Regulated Markets: Safety First with Openness for Innovation

In the fast-paced world of transportation, safety regulations are the cornerstone of every innovation. At Omni3D, we understand this responsibility deeply. That's why our industrial extrusion 3D printing technology prioritizes not just cutting-edge capabilities, but also strict adherence to critical safety standards.

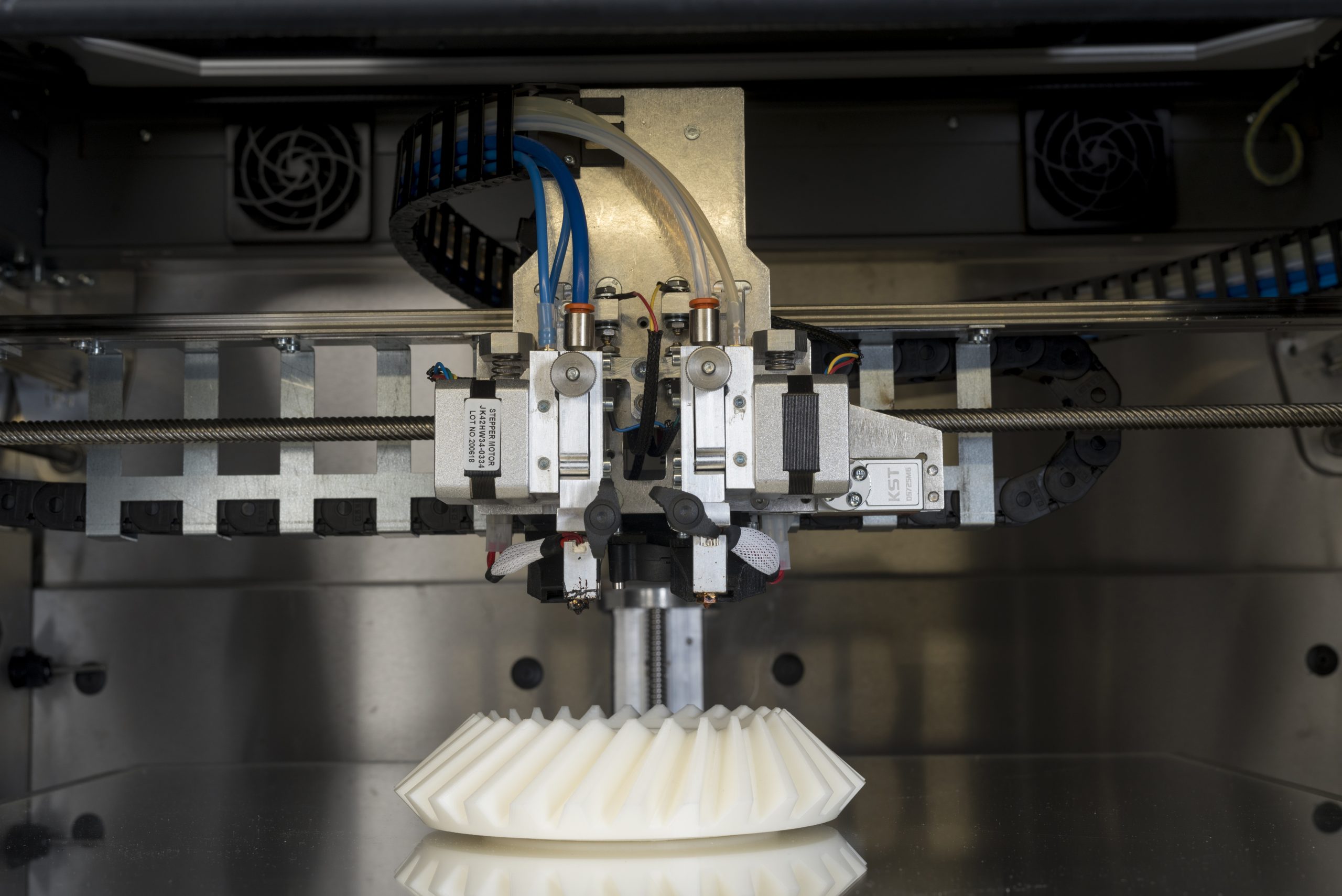

Refurbishment of a vacuum pump using 3D printing technology

Luk-Plast, a plastics recycling company, commissioned us to print an impeller for a vacuum pump in a process line where waste plastic film is recycled into pellets.

Our job was to design the ...

No results found.

Trusted by

Latest blog posts

3D Printing on Textiles

3D...

3D printing replacing steel

Eba sp....

Chamber Temperature’s Impact on Strength in material extrusion

Achieving optimal part quality in additive manufacturing material extrusion often hinges on factors beyond mere geometry and material selection. One such critical aspect is the controlled thermal environment provided by heated chambers, particularly when working with advanced materials like super polymers.