Resources

Insights, trends, and actionable strategies for aerospace, automotive, industrial maintenance, and defense industries using cutting-edge large-format 3D printers.

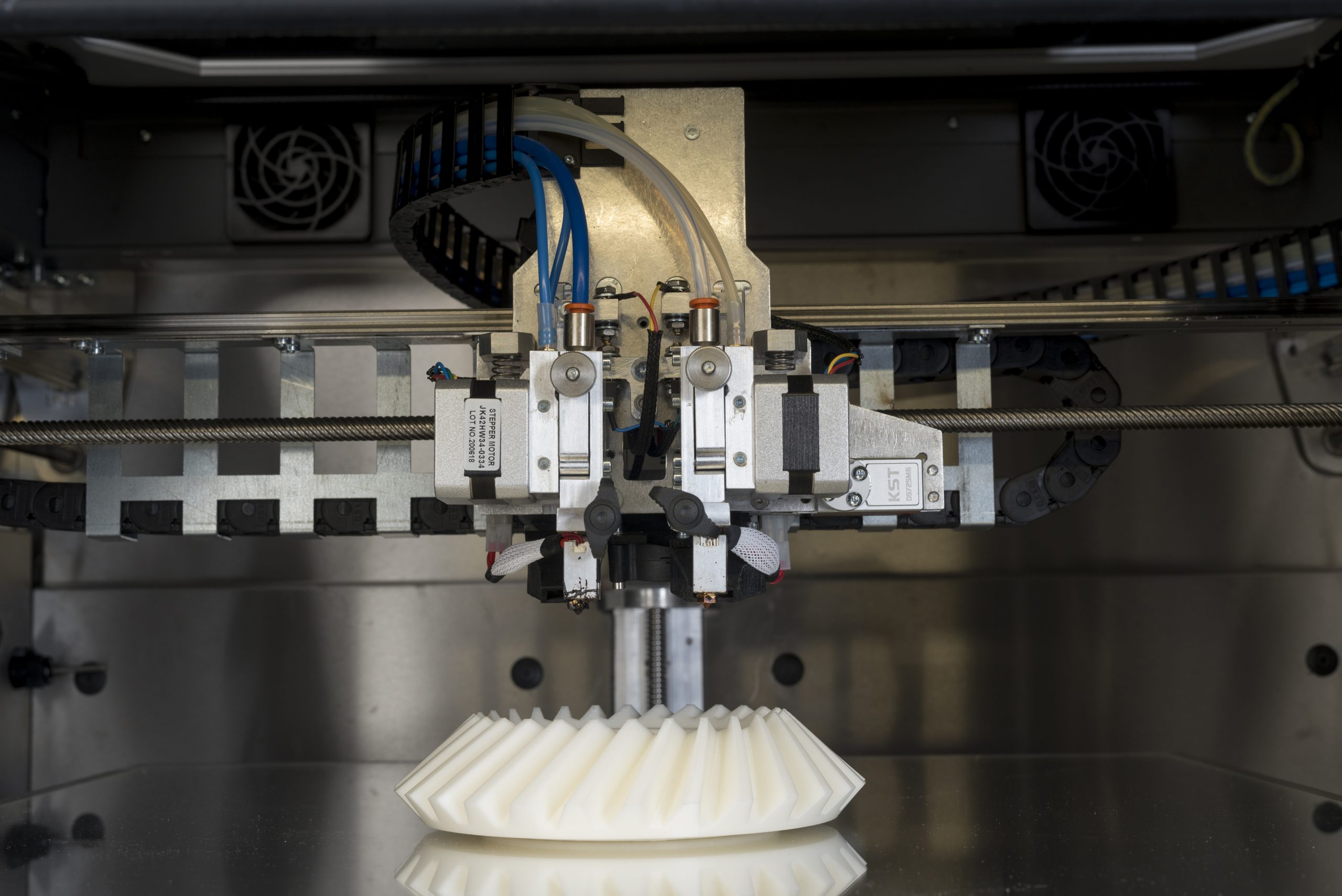

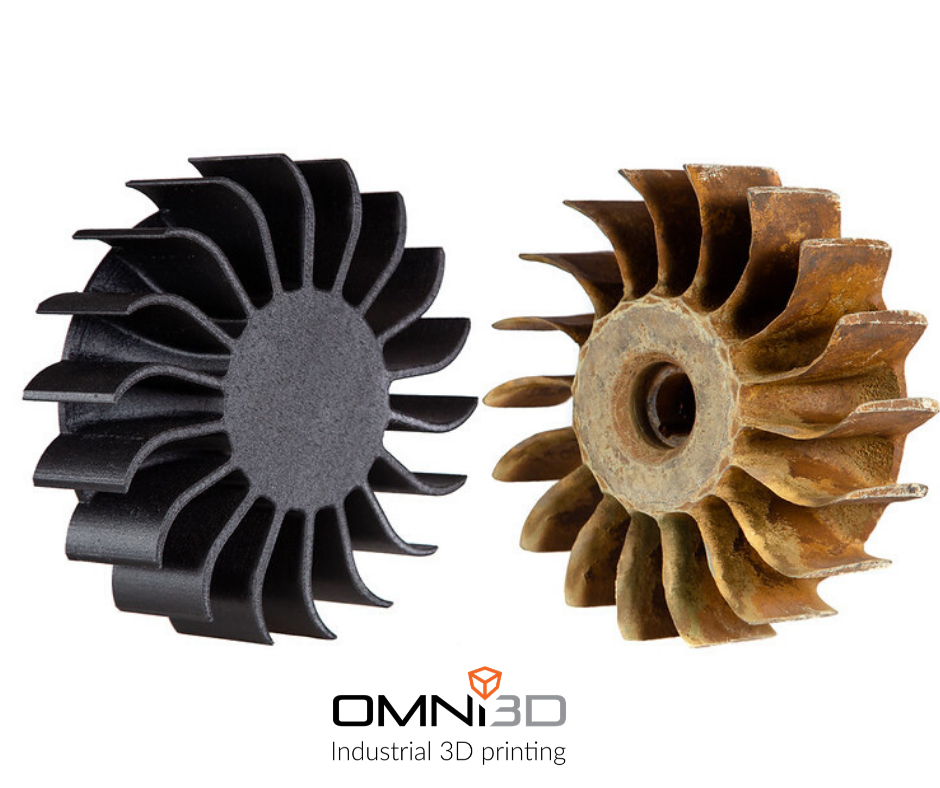

Refurbishment of a vacuum pump using 3D printing technology

Remote 3D printer management

Remote control housing – 3D printing in the production of final components

Replacing Metals With 3D-Printed: High-Performance Polymers

Reviving Obsolete Machinery: On-Demand 3D Printing for Agricultural Spare Parts

Revolutionizing Aerospace Tooling: How Collins Aerospace Cut Costs and Lead Times with 3D Printing

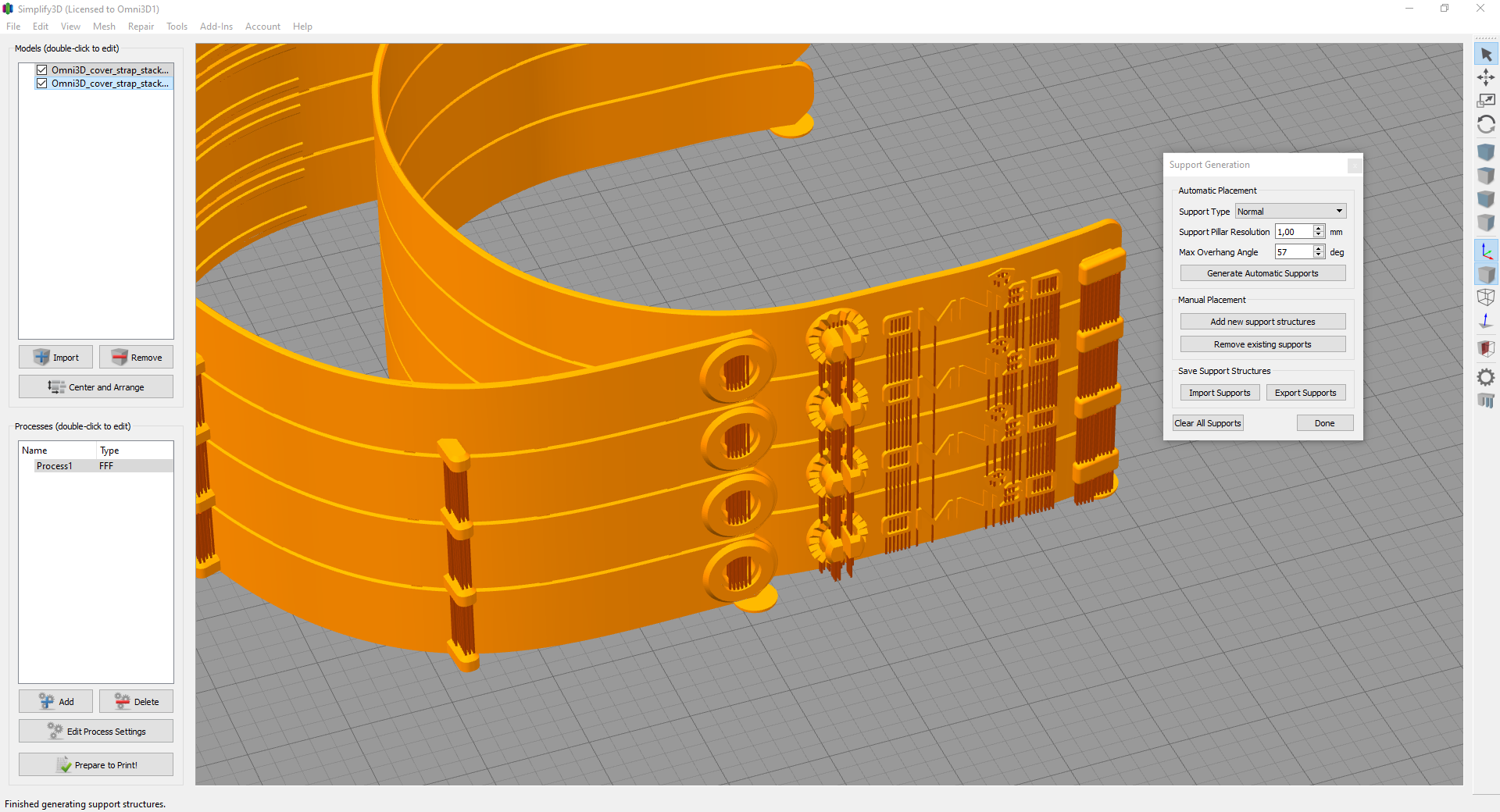

Simplify3D: Quick editing of support structures

Soaring to New Heights: Material Extrusion takes Flight in Aerospace Applications

Soaring to New Heights: Material Extrusion takes Flight in Aerospace Applications

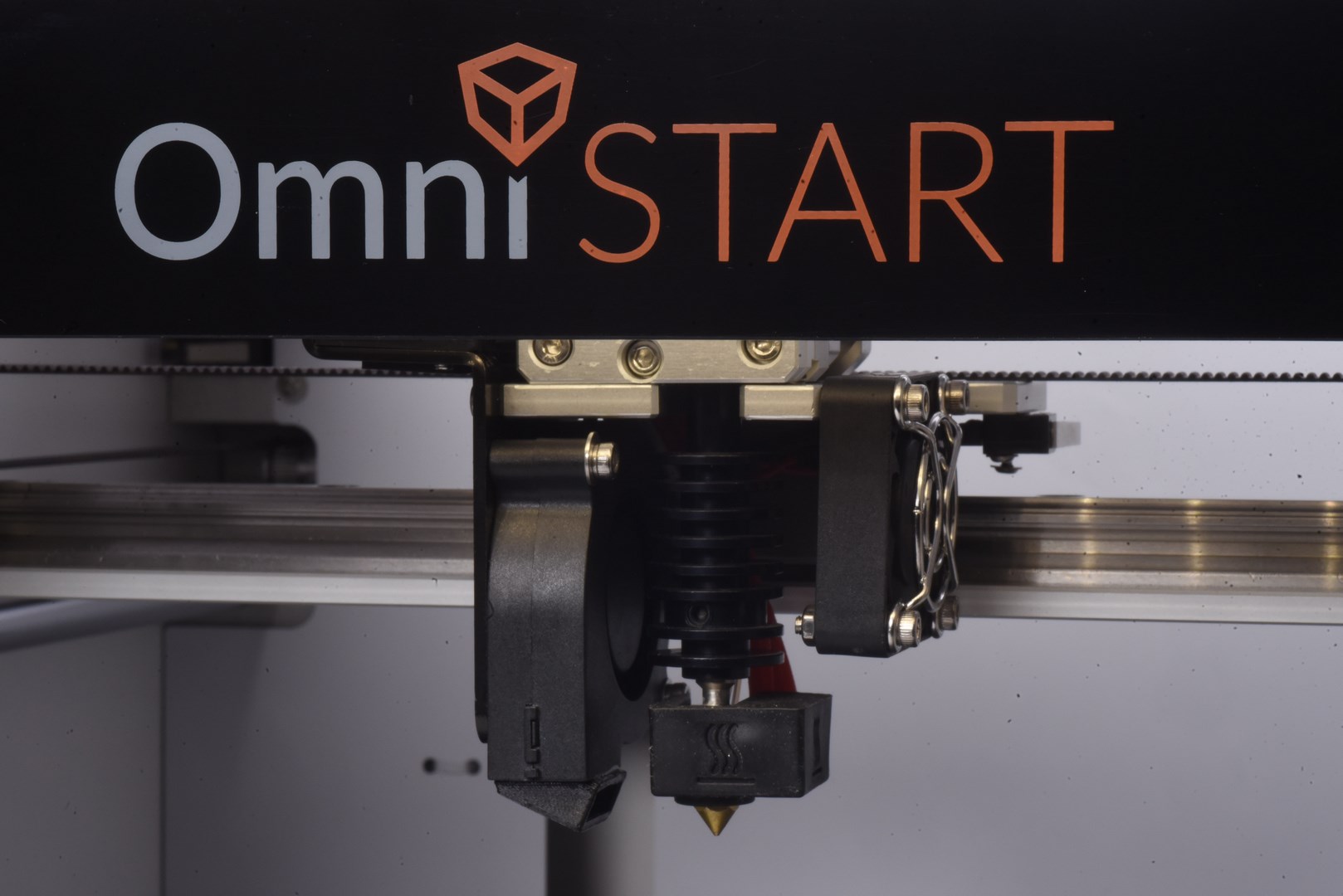

START with 3D printing

Trusted by

Latest blog posts

Large-Format, Heated Chambers: The Cornerstone of Defense-Grade 3D Printing

Reliability and performance are paramount in defense and 3D printing has emerged as a transformative technology. The successful implementation of this technology hinges on several critical factors, with chamber size and temperature control standing out as particularly crucial to blend 3D printing into established manufacturing processes.

Material Matters: Choosing the Right Filament for Defense Applications

When it comes to 3D printing for defense applications, material selection is paramount. The ability to choose the right filament is crucial for producing parts that meet the stringent requirements of military operations and lasts.

Maximizing 3D Printing Success: The Key to Drying Filament for High-Temperature Polymers

Welcome to our blog! In this post, we will delve into a crucial aspect of achieving optimal results in material extrusion 3D printing: the importance of drying filament, especially when working with engineering high-temperature polymers. We will explore the benefits of filament drying and share valuable insights on how to reduce costs along the way.