Resources

Insights, trends, and actionable strategies for aerospace, automotive, industrial maintenance, and defense industries using cutting-edge large-format 3D printers.

The Role of Adhesives in FDM 3D Printing: Your Key to Perfect Prints

The Use of 3D Printing in AIRFUKA’s Touchless Car Dryers

Volkswagen – Innovative production thanks to the use of 3D printing from Omni3D

Wake up creativity with 3D Printing

What is fff 3d printing technology?

What is the difference between an industrial 3D printer and a home desktop 3D printer?

What will bring the 2021 in 3D printing?

When and why is it worth outsourcing 3D printing services?

Which filament to choose for spare parts production?

Trusted by

Latest blog posts

Soaring to New Heights: Material Extrusion takes Flight in Aerospace Applications

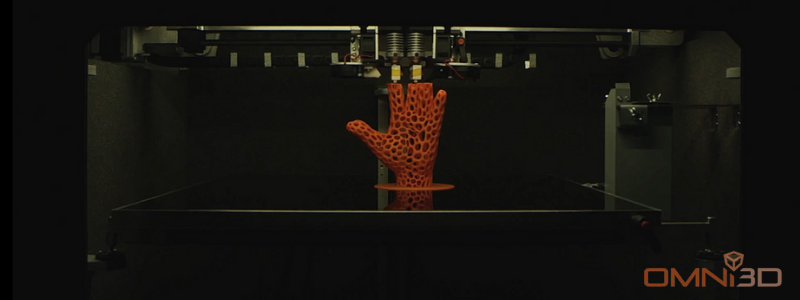

Building upon our commitment to safety-first innovation in regulated markets, Omni3D’s industrial extrusion 3D printing technology is taking flight in the demanding world of aerospace. This blog entry, a continuation of our exploration of 3D printing within highly regulated industries, dives deeper into the specific considerations and exciting possibilities for large-format material extrusion within the aerospace sector.

Mastering the Cool-Down: Thermal Management in Large-Format Industrial 3D Printing

In the realm of large-format industrial 3D printing, achieving optimal part quality demands meticulous attention to every stage of the process. While the excitement often lies in the creation of complex geometries, in industrial applications the often-overlooked cooling phase is paramount for ensuring dimensional accuracy, mechanical properties, and overall part performance.

Pioneering Industrial Extrusion 3D Printing for Regulated Markets: Safety First with Openness for Innovation

In the fast-paced world of transportation, safety regulations are the cornerstone of every innovation. At Omni3D, we understand this responsibility deeply. That’s why our industrial extrusion 3D printing technology prioritizes not just cutting-edge capabilities, but also strict adherence to critical safety standards.