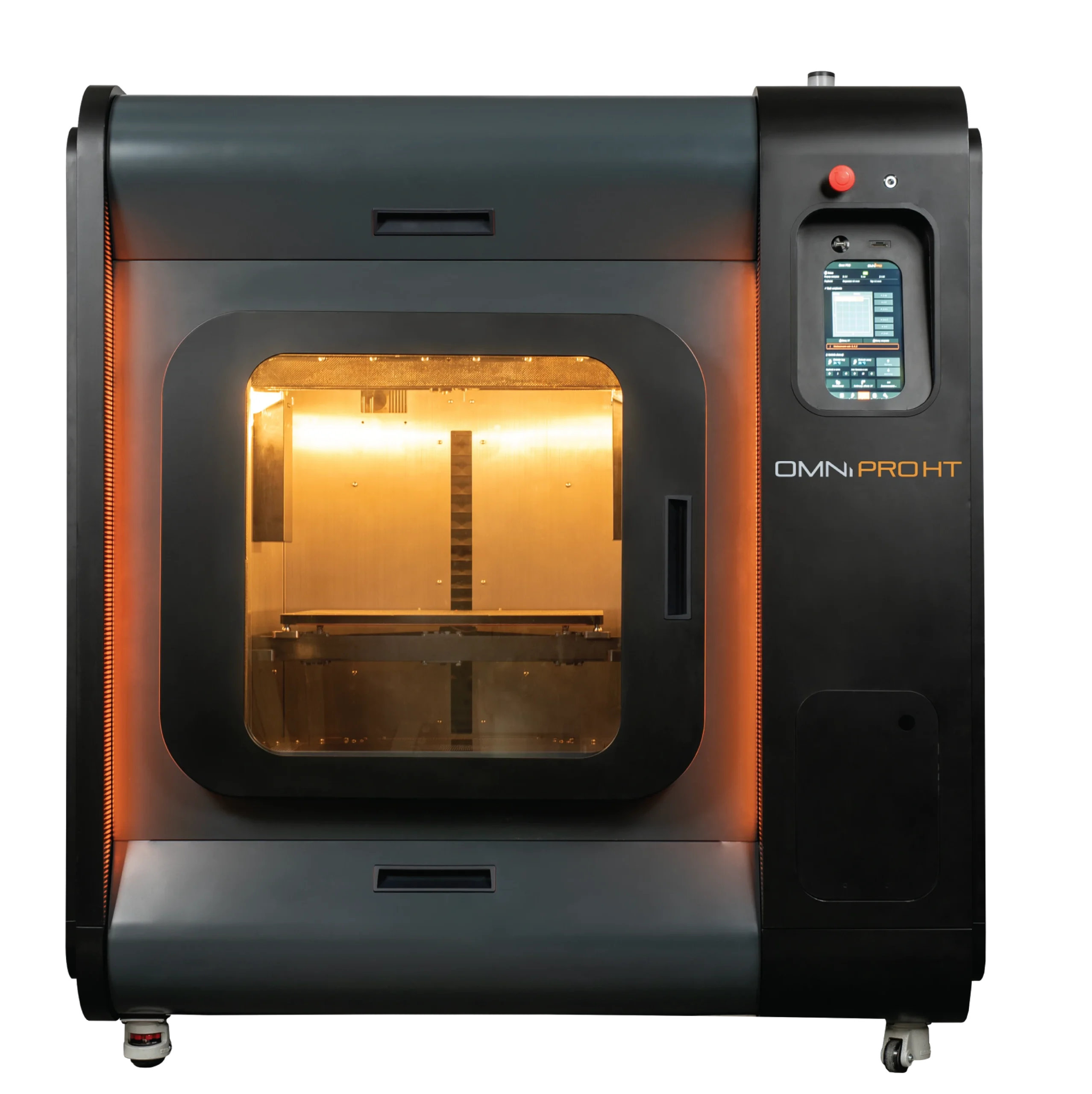

HIGH-PERFORMANCE

LARGE-FORMAT FUNCTIONAL PARTS

Industrial high-performance parts

Strong parts, resistant to extreme temperatures or chemical agents, with exacting industry certifications

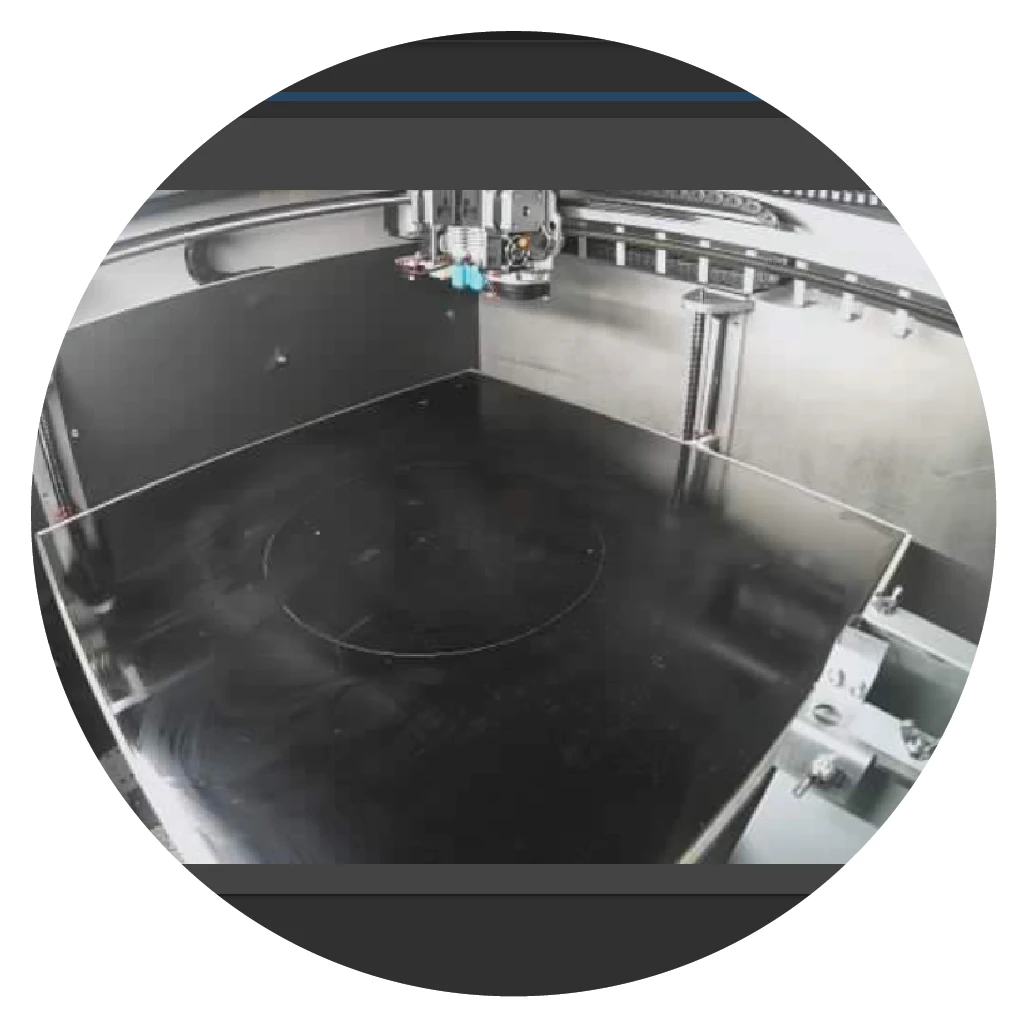

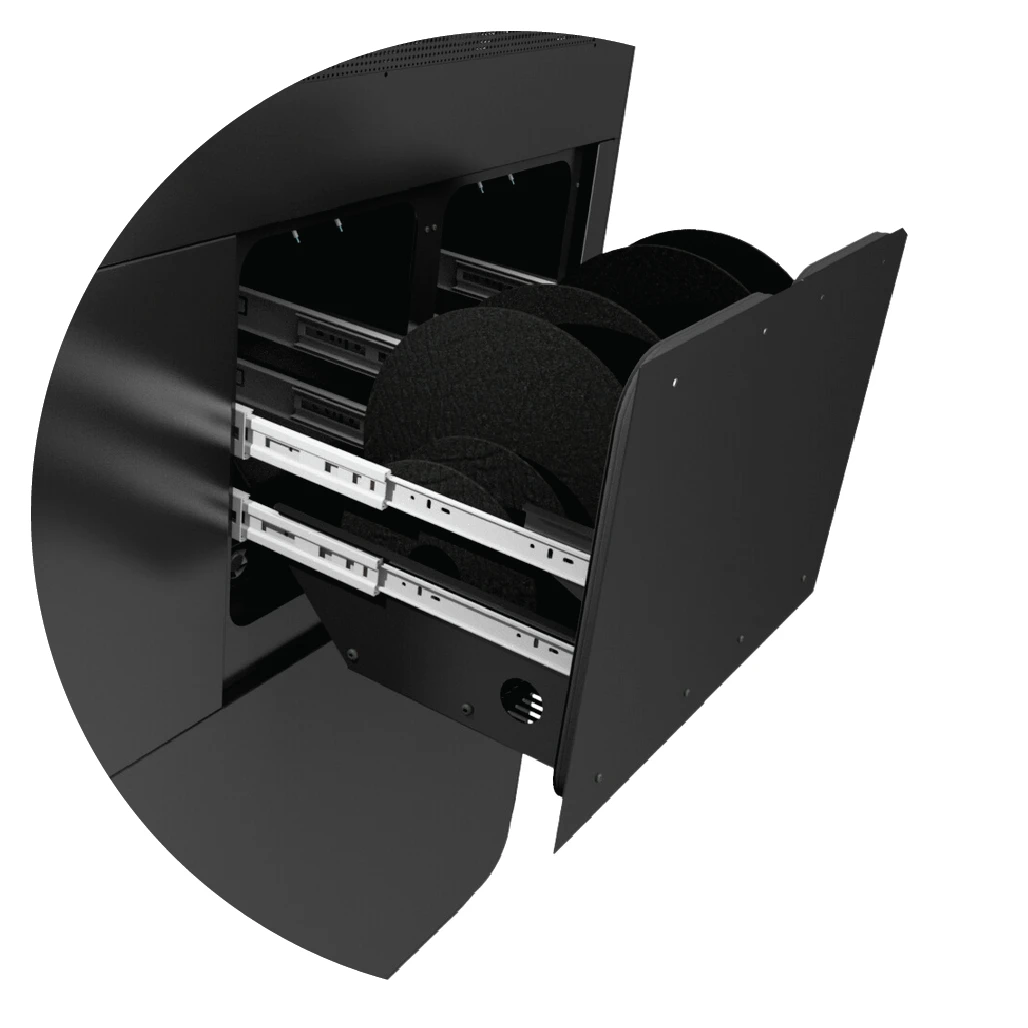

220°C Heated chamber

Remote camera supervision

Build Volume 500 x 500 x500

Built-in filament dryer for 4 spools up to 120°C

The Omni PRO HT offers unique benefits to industrial manufactureres

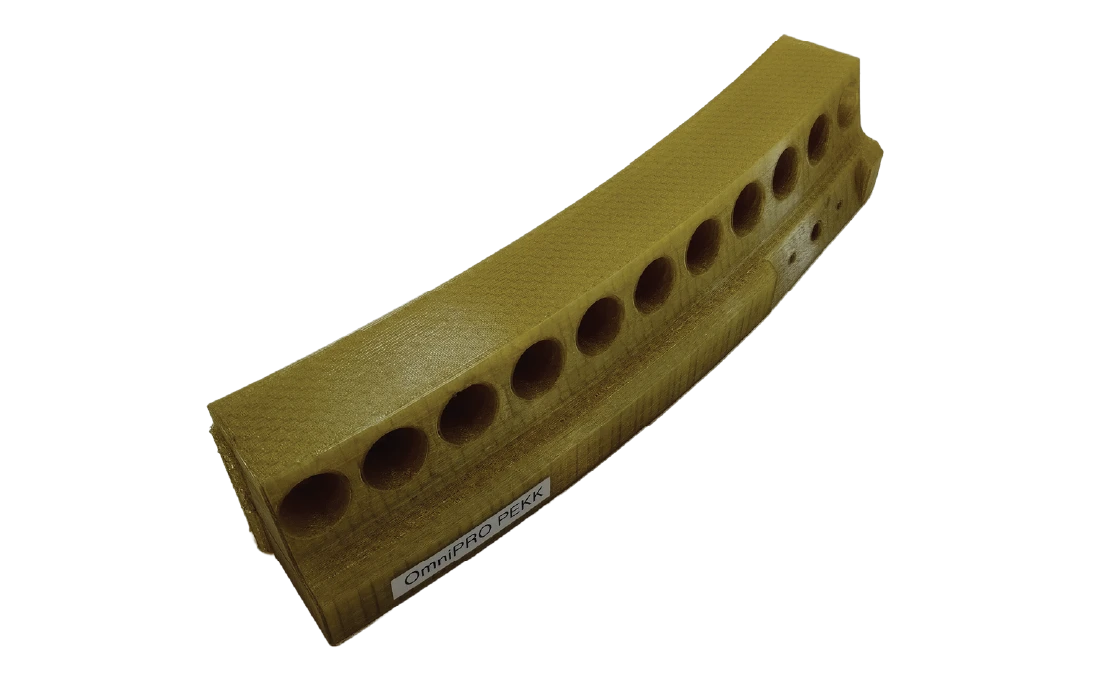

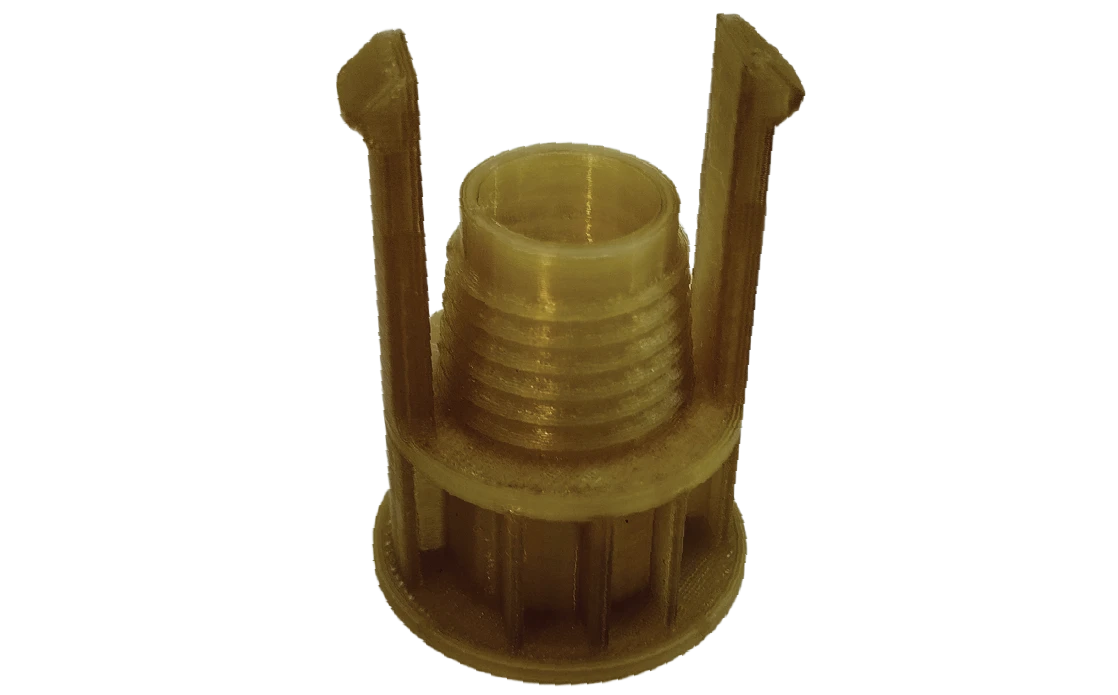

Large advanced engineering parts in PPS, GF-PPS, and PEKK.

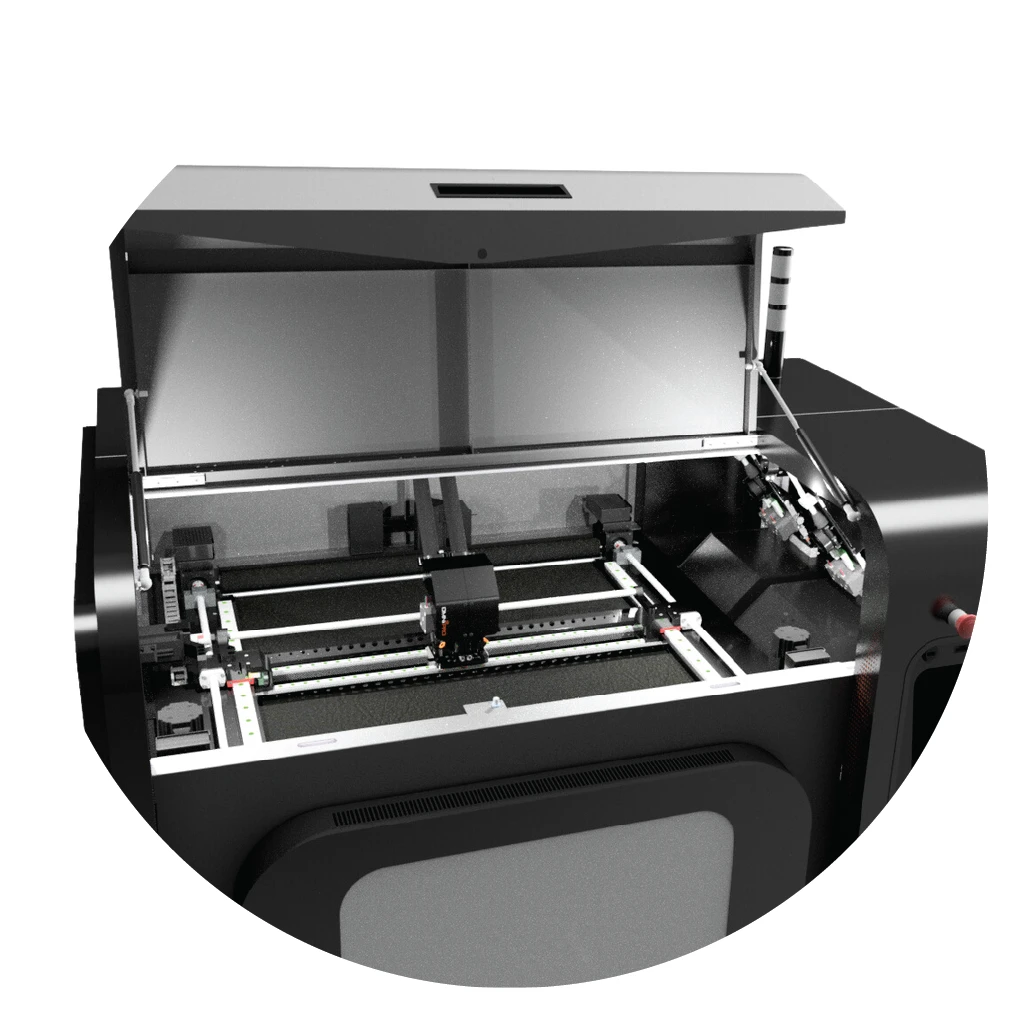

The Omni PRO is optimized for reliably 3D printing big components, empowering you to create high-performance components for demanding applications.

Part performance with proven material compatibility

The Omni PRO’s precisely controlled environment ensures consistent and high-quality results when printing PPS, GF-PPS, and PEKK, maximizing the performance characteristics of these advanced materials.

Efficient integration into production environments.

The Omni PRO simplifies the printing process for PPS, GF-PPS, and PEKK, reducing development time and accelerating time to market.

Robust, low-maintenance platform for production efficiency.

Built for continuous operation, the Omni PRO minimizes downtime and maintenance costs, ensuring consistent and reliable production of high-performance parts.

COMPARISON TABLE

OmniPRO HT |

OmniTECH |

|

|---|---|---|

| Build size | 500 × 500 × 500 mm | 500 × 500 × 570 mm |

| MAX. HEAD TEMPERATURE | 500°C | 420°C |

| Max Chamber temperature | 220 °C (ACTIVELY HEATED) | 70 °C (ACTIVELY HEATED) |

| BUILT-IN FILAMENT DRYER | YES | NO |

| Brochure | Download Spec Sheet | Download Spec Sheet |

Need assistance? Speak with one of our specialists today

Materials

At Omni3D, we believe in the power of choice. Our open material systems allow you to explore a vast array of materials, tailored to your specific needs. From engineering-grade thermoplastics to specialty filaments, our printers are designed to handle it all.

Omni PRO compatible materials include:

PPS

Car door handle prototype

GF PPS

Train folding

tables

PEI

BMP-1 Manhole

key

PEKK CF

Gauge

PEKK

Window roller

part

Applications

Omni proHT Specifications

| Build volume XYZ | 500 x 500 x 500 mm |

| Chamber | Enclosed, Isolated and actively heated |

| Max. chamber temperature | 2200°C |

| Max. head temperature | 500°C |

| Max. platform temperature | 220°C |

| Built-in filament dryer for 4 spools | Yes (max. 4 x 3 kg), up to 120°C |

| Automatic change of filaments | Yes |

| Built-in accessory drawer | Yes |

| Max. power consumption | 10kW |

| Printer dimensions | 160 x 110 x 150 cm |

| Printer weigth | 50 kg |

| Brochure | DOWNLOAD BROCHURE |

Trusted by

Latest blog posts

3D Printing Impossible-to-Machine Large 3D Parts for Hexapods

More...

On-Demand Parts for Legacy Armor: Maintaining BMP-1 Vehicles with Omni3D’s Large-Format Printing

Maintainin...

3D Printed Fairings for Suborbital Rocket Boosters: Lighter, Faster, Mission-Ready

In the...