METAL POWDER BED FUSION

3D PRINTERS

Omni3D's advanced Powder Bed Fusion (PBF) solutions.

Omni3D industrial metal 3D printing PBF technology offers a precise method for producing geometrically complex components from various metal alloys.

Our metal 3D printing solutions provide a complete implementation package for the most demanding industrial environments. This includes 3D printers, necessary auxiliary equipment, materials, comprehensive onsite installation, and full operational training for your team. This integrated approach ensures a seamless transition and optimal performance in your facility.

3D PRINTERS

REDUCED MATERIAL COST

Our LPBF process minimizes waste by efficiently reusing pre-sifted metal powder, leading to significant cost savings.

MANUFACTURING WITHOUT LIMITS

Create complex geometries, internal cavities, and conformal cooling channels unattainable with conventional techniques.

FASTER TIME-TO-MARKET

Bypass traditional tooling and accelerate your metal product development with direct, rapid manufacturing.

LIGHTWEIGHT AND HIGH-PERFORMANCE DESIGNS

Optimize metal part shapes topologically during prototyping for substantial weight reduction and improved functionality.

UNLIMITED MATERIAL POSSIBILITIES

Optimize metal part shapes topologically during prototyping for substantial weight reduction and improved functionality.

OUTSTANDING MECHANICAL PROPERTIES

Optimize metal part shapes topologically during prototyping for substantial weight reduction and improved functionality.

Need know more about consumables, accessories, or spare parts for your Metal PBF 3D printer?

Materials

At Omni3D, we believe in the power of choice. Our open material systems allow you to explore a vast array of materials, tailored to your specific needs.

Compatible materials include:

|

Aluminum AlSi10Mg

|

|

Titanium Ti6Al4V

|

|

Cobalt-chromium CoCrMo

|

|

Steel grade AISI 316L

|

|

Inconel 625

|

Inconel 718

|

AUXILIARY EQUIPMENT

Vacuum powder transporter OMNI-VPT

Device designed for powder removal after 3D printing process completion within the build chamber of the 3D printer

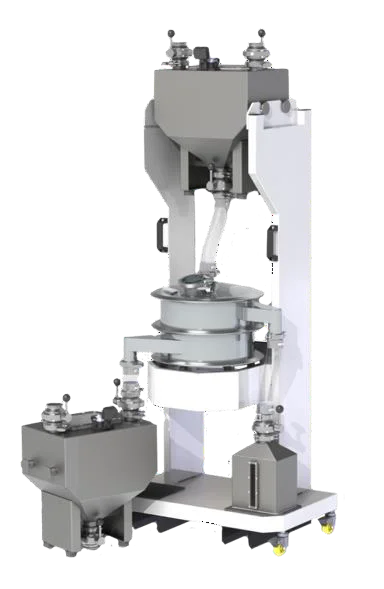

Automated Powder Sieving Unit

OMNI-APSU

Device designed for sieving, mixing and homogenization of metal powder in preparation for reuse in metal 3D printer

Build chamber unpacking module OMNI-BCUM

Device designed for powder removal after 3D printing process from the printer component within the removal build chamber

COMPARISON TABLE

OMNIM150 |

OMNIM280 |

|

|---|---|---|

| Build Size | 150 × 150 × 180 mm | 280 × 280 × 500 mm |

| Configuration of the Optic System | Single | Single / Double (optionally) / Quadruple (optionally) |

| Rated Optic Power of the Laser | 200 W | 1 × 500 W / 2 × 500 W (optionally) / 4 × 500 W (optionally) |

| Layer Thickness | 20 – 200 µm | 20 – 200 µm |

| Laser Beam Focus Diameter | 45 µm | 75 – 200 µm |

| Laser Beam Positioning Accuracy | 0.15 µm | 0.28 µm |

| Brochure | Download Spec Sheet | Download Spec Sheet |

Have questions? Get in touch with our sales team now!

Our technology is trusted by