Case study: Common S.A. (Energy sector)

High dimensional accuracy for end-use parts

3D printing is often associated with prototyping. This project highlights something different: 3D printing for end-use production, where dimensional accuracy and repeatability are non-negotiable.

The challenge

Common S.A. is a Polish engineering company with 35 years of experience in designing and producing industrial gas metering systems that meet gas-industry standards and require high measurement precision.

New customer expectations and stricter environmental requirements pushed the team to reduce noise generated by volumetric metering devices, specifically rotary gas meters. At the same time, the solution needed to be original enough to support patent protection and enable expansion into new markets.

Because development required many iterations and tests, the team needed a production method that could deliver:

- low-cost development of complex prototypes,

- high dimensional accuracy below 0.1 mm, and

- geometry that traditional machining could not produce.

Two constraints made conventional methods impractical:

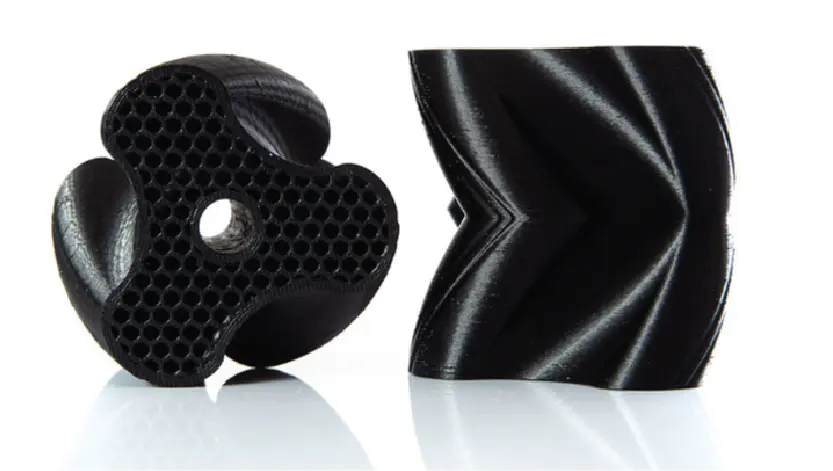

- a cycloidal external profile that is extremely difficult to machine,

- an internal honeycomb-like openwork structure that standard machining cannot produce.

The application

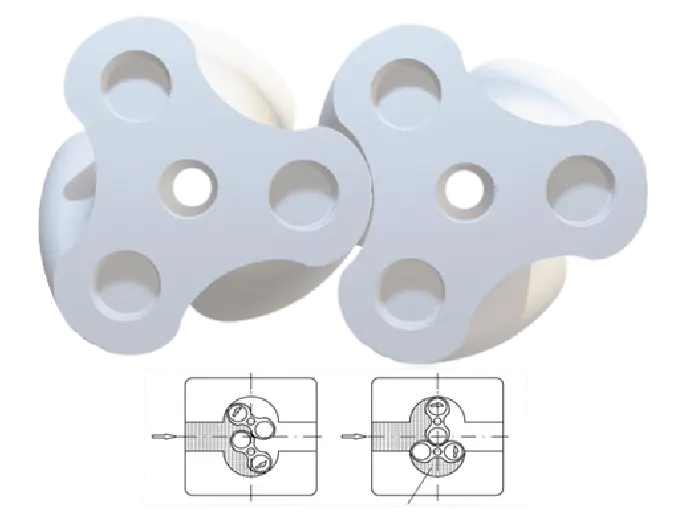

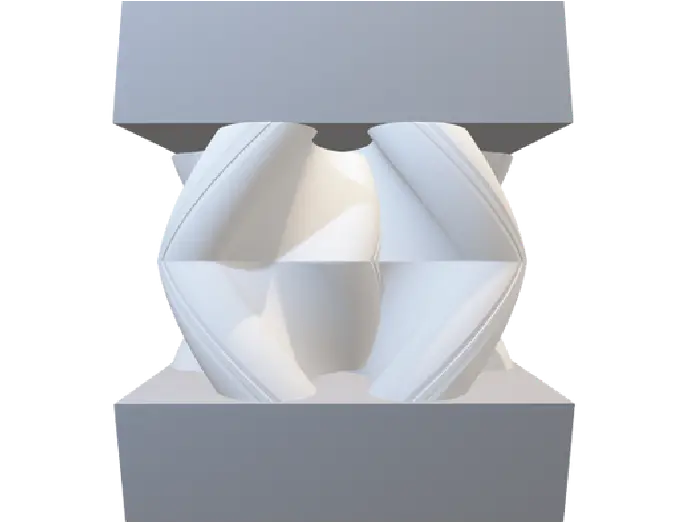

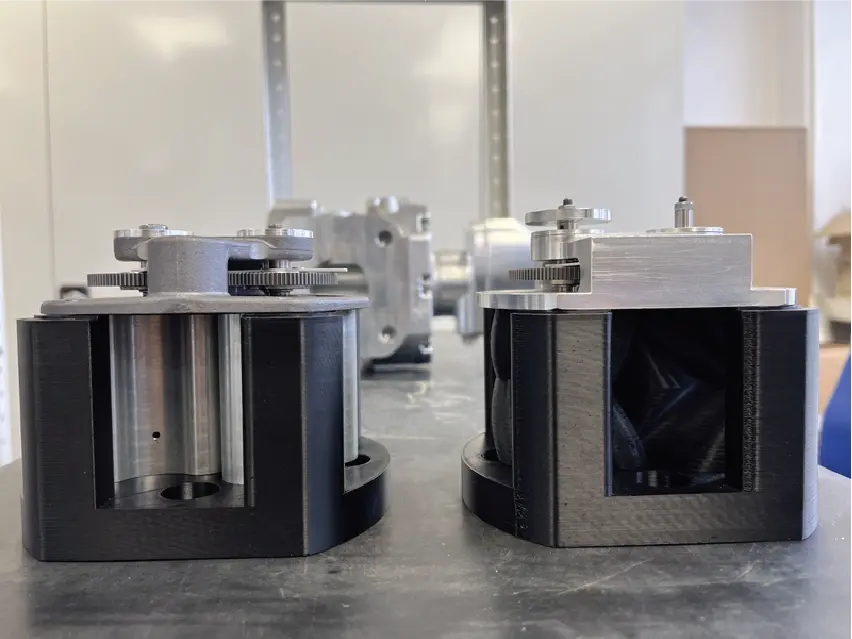

Common S.A. developed a pulse-free, low-noise rotary gas meter with high metrological performance. The design uses a pair of helically twisted rotors working together inside a closed measuring chamber. This approach eliminates axial forces on rotor shafts and supports durability and comfortable operation.

The remaining bottleneck was manufacturing. The rotor geometry and dimensional requirements made 3D printing the only feasible production method for this design.

After internal evaluation, FDM was selected as the most suitable approach, provided the system could consistently achieve:

- surface reproduction accuracy below 0.1 mm,

- axial parallelism of planes below 0.05 mm,

- and controlled deviation over the entire surface, not only along X, Y, Z linear dimensions.

Key geometric and tolerance requirements

Clearances and non-contact motion

- The two rotors operate without touching each other, maintaining 0.1 mm clearance between parts.

- The rotors are enclosed by top and bottom housings, with 0.1 mm clearance between parts and the housing.

Alignment and deviation limits

- Top and bottom surfaces are perpendicular to the central axis.

- The entire external surface deviates from the axis by no more than 0.08 mm.

- Positioning holes require 0.05 mm accuracy.

The solution: Omni NOVA calibration discipline

After testing multiple machines and reference prints from leading 3D printer manufacturers, the selected solution was Omni NOVA, paired with precisely set axes using backlash-free screw drive systems.

A dedicated test print and calibration process were developed to ensure the rotor would meet the dimensional accuracy targets.

Omni NOVA systems used to achieve the result

Omni NOVA, which is equipped with:

- automatic X and Y axis squareness adjustment,

- automatic bed leveling,

- precisely manufactured axes with screw drives.

As noted by Krzysztof Kardach (3D Printing Technologist, Omni3D), industrial accuracy is not only about meeting X, Y, Z linear dimensions. It is also about maintaining controlled deviation across the entire surface of the object.

Material choice: why ESD PETG matters in gas metering

For this application, PETG ESD was selected to print the rotors.

The reason is safety and reliability in environments where flammable gas is present:

- measuring devices for flammable gases must prevent electrostatic discharges to reduce explosion risk,

- ESD filaments use additives that dissipate accumulated charge and help prevent discharge formation,

- the material also offers high impact resistance, supporting durability and strength.

An optimized print code enabled printing a single rotor in under 4 hours.

Results

The project enabled:

- fast production of precise rotors in PETG ESD,

- manufacturing cost reduction by a factor of 5,

- and the transition to serial production using multiple Omni3D systems.

The work also supported a patent application at the European Patent Office, resulting in 10 years of patent protection for the designed devices.

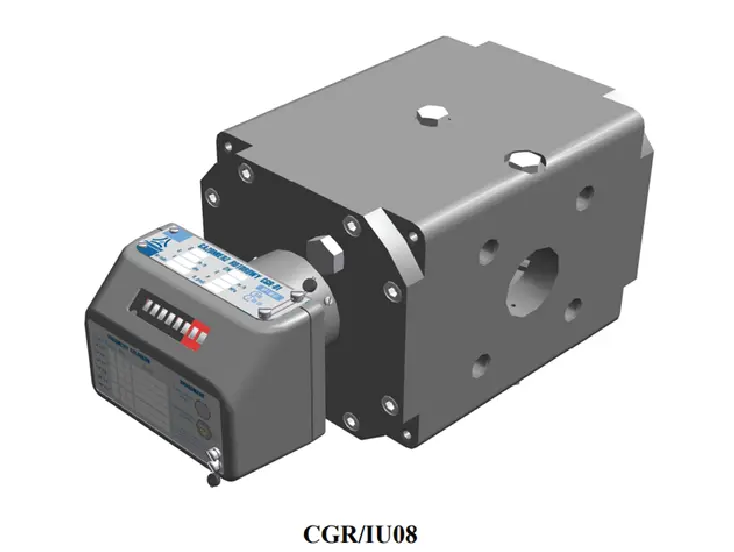

The CGR-05 rotary gas meter received a medal at the 12th EXPO-GAS Gas Engineering Fair 2023.

Work continues to expand capability toward high-pressure gas measurement.

Technical summary table

| Item | Value |

|---|---|

| Industry | Energy |

| Client | Common S.A. |

| Part | Rotor for pulse-free rotary gas meter CGR-05 |

| Category | End-use parts |

| Technology | FDM |

| Material | PETG ESD (ESD-PETG) |

| Print time | Under 4 hours per rotor |

| Key clearances | 0.1 mm between rotors; 0.1 mm to housing |

| Key accuracy targets | <0.1 mm dimensional accuracy; <0.05 mm plane parallelism; 0.08 mm max surface deviation; 0.05 mm hole positioning |

| Printer | Omni NOVA |

Practical takeaways

- For gas metering components, dimensional accuracy and repeatability must be evaluated across the full surface, not only along linear axes.

- When geometry includes cycloidal profiles and internal openwork structures, FDM can be the enabling manufacturing method.

- In flammable gas environments, ESD materials can be a functional requirement, not a nice-to-have.

- Machine mechanics and automation help, but calibration discipline can be equally decisive.

FAQ

What is the main benefit of printing the CGR-05 rotor with FDM?

It enables complex rotor geometry and high dimensional accuracy that conventional machining cannot produce cost-effectively, especially when many test iterations are required.

Why use PETG ESD for a gas metering rotor?

PETG ESD helps dissipate electrostatic charge and reduces the risk of discharge formation, which is critical in devices used with flammable gases. It also provides high impact resistance for durability.

What tolerances were required for the rotor system?

Clearances of 0.1 mm between rotating parts and to the housing, hole positioning accuracy of 0.05 mm, and maximum surface deviation of 0.08 mm from the axis, alongside sub-0.1 mm dimensional accuracy targets.

How fast can one rotor be produced?

A single rotor can be printed in under 4 hours with an optimized print code.

What was the business impact?

The process enabled faster production and a five-times reduction in manufacturing cost, supported serial production, and contributed to patent protection and industry recognition.