by admin | Feb 12, 2024 | Case Study, Maintenance

John Cockerill Services is a leading provider of industrial equipment maintenance solutions for a large number of industries such as chemicals, steelmaking, petro-chemicals, railways, ports, inland waterways, cement, mines and quarries, renewable and nuclear energy. It designs and supplies unique pieces of new industrial equipment, components and sub-assemblies (shunting locomotives, gearboxes, reducers, butterfly valves and diesel engines) along with spare parts for legacy equipment repair.

by admin | Feb 10, 2024 | Case Study, Maintenance

The possibilities offered by 3D printing technology have been used for a long time in the automotive industry and at every stage of production – from prototyping to the production of spare parts and final elements. The available materials allow us to print not...

by admin | Feb 10, 2024 | Knowledge

Building upon our commitment to safety-first innovation in regulated markets, Omni3D’s industrial extrusion 3D printing technology is taking flight in the demanding world of aerospace. This blog entry, a continuation of our exploration of 3D printing within...

by admin | Feb 10, 2024 | Case Study, Knowledge, Maintenance

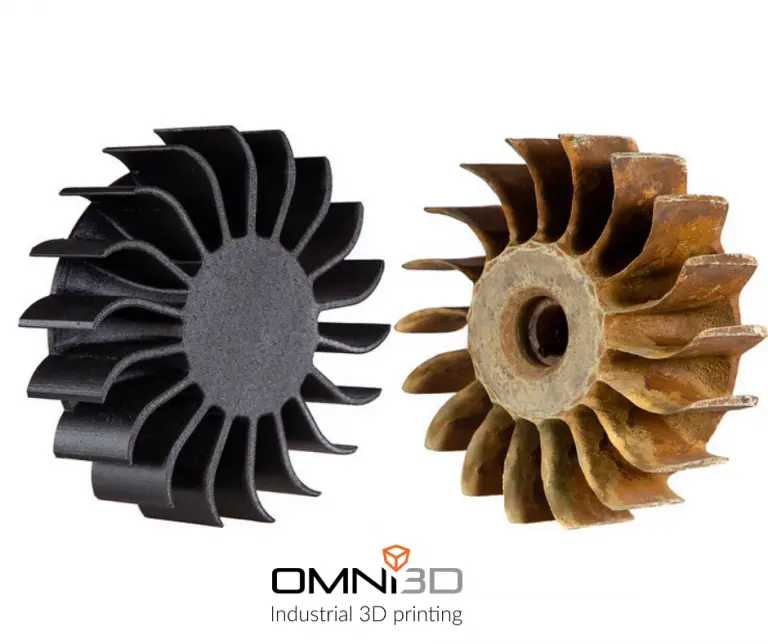

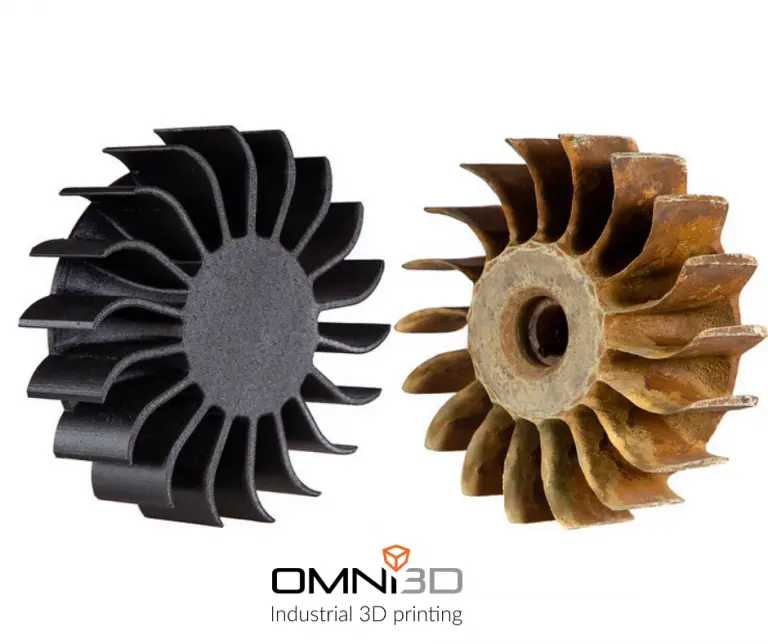

Luk-Plast, a plastics recycling company, commissioned us to print an impeller for a vacuum pump in a process line where waste plastic film is recycled into pellets. Our job was to design the impeller to effectively replace the existing brass component, both on a...

by admin | Jun 3, 2021 | Knowledge

In the FDM / FFF technology there is a belief that anyone who can print anything more than PLA, can be treated as a solution for the engineer and industry. What is professional, industrial 3D printing? Where is the line that mark a border between the printers for amateurs, semi-professional and the industry printers for engineers and production? Why, despite many years of existence of 3D printing, the knowledge related to it, is not common? I will try to define the line between, explain the aspects, both technological and usable that is associated with professional 3D printing. That needs to be done, to know what it is, what it gives and makes it different from desktop and semi-professional devices.