by admin | Apr 8, 2021 | Case Study

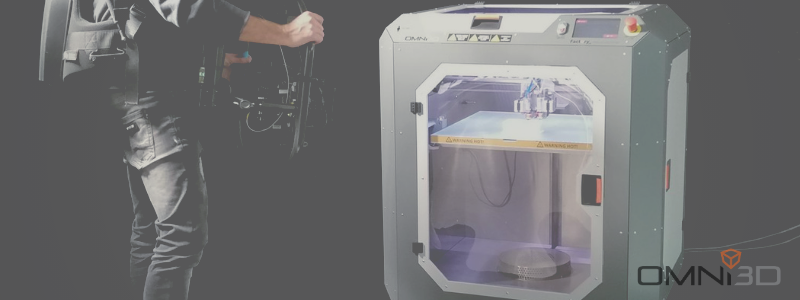

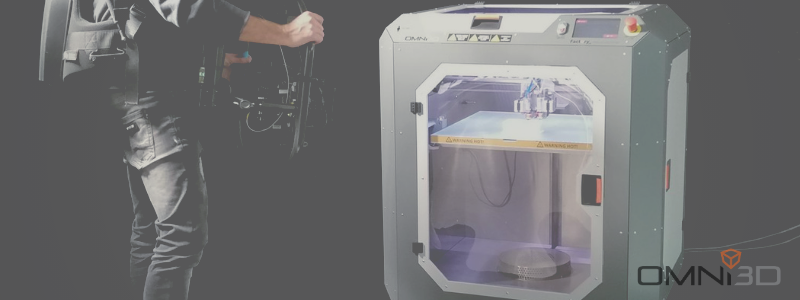

3D printing allows you to quickly check the accuracy of the dimensions before ordering an expensive form for the production of the tool. Thanks to the Omni3D printer, the customer could try out the designed tool and apply corrections before ordering the production of the final product.

by admin | Mar 30, 2021 | Knowledge

ABS, i.e. acrylonitrile butadiene and styrene, is a material that almost all of us have had a contact with. Car parts, machine elements and tool housings are made of ABS, but it is also used in the Electronics Home Appliances and the toy industry.

by admin | Mar 24, 2021 | Knowledge

3D printing is not only limited to small parts and models that can be produced with desktop printers. The widespread use of this type of printers causes many people to believe that the dimensions of the printed elements are limited. The alternative turns out to be printing entirely. Some machines offer a very large print volume, which can reach even one cubic meter! This type of professional large-format 3D printer is presented by the industrial Omni3D printers.

by admin | Mar 18, 2021 | Knowledge

Metal housing, accuracy, speed, build volume enabling the printing of smaller elements – these are only some of the features of desktop 3D printers Omni200 / 200 (CF) from Omni3D. Most importantly, their high quality is also accompanied by an attractive price.

by admin | Mar 16, 2021 | Knowledge

The more we delve into the world of filaments and the possibility of their use in various industries and sectors, the more often we think about chemical “durability”. The field of research in this aspect is not yet developed – and some experiments are burdened with a long term of feasibility. What does it mean?