In the demanding world of agriculture, downtime is costly. When critical machinery parts become obsolete or unavailable, it can halt operations and disrupt productivity. That’s precisely the challenge faced by a recent client with a Matrot self-propelled sprayer. Fortunately, Omni3D’s Printroom stepped in, demonstrating the power of on-demand 3D printing to breathe new life into aging equipment.

The Challenge: Obsolete Parts and Urgent Needs

Our client encountered a common problem: an essential spare part for their Matrot sprayer was no longer available for purchase. This situation threatened to sideline their machine, impacting their farming operations. Faced with limited options, they turned to Omni3D’s 3D printing services for a rapid and cost-effective solution.

The Solution: Rapid Prototyping and On-Demand Production

At Omni3D’s Printroom, we understand the urgency of such situations. We leveraged our expertise in industrial 3D printing and reverse engineering to quickly address the client’s needs. The process involved:

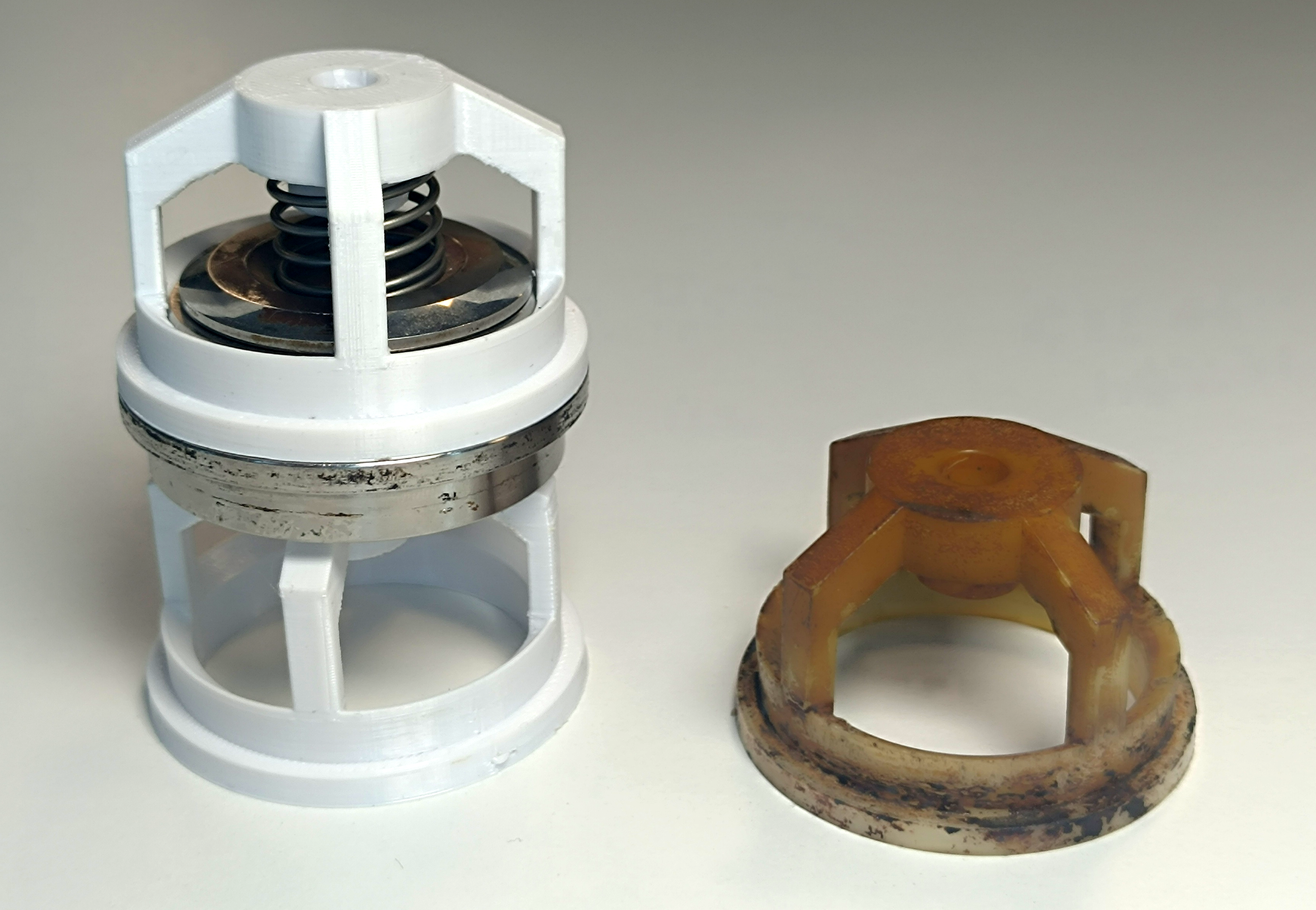

- Part Design: Our experienced team designed a 3D model of the obsolete part based on the original component.

- Material Selection: We chose PET-G 32, a durable and versatile material, ideal for agricultural applications due to its resistance to environmental factors.

- Express 3D Printing: Using our advanced large-format FDM 3D printing technology, we produced three replacement parts in just 2.5 hours, each weighing 24 grams.

The Results: Minimizing Downtime and Maximizing Efficiency

The 3D-printed parts perfectly matched the original component, enabling the client to quickly restore their Matrot sprayer to operation. This success story highlights the key benefits of our 3D printing services:

- Rapid Turnaround: We delivered functional spare parts in a fraction of the time compared to traditional manufacturing methods.

- Cost-Effectiveness: 3D printing eliminates the need for expensive tooling and molds, making it a cost-efficient solution for low-volume production and spare parts.

- On-Demand Availability: We can produce parts precisely when needed, eliminating storage costs and minimizing downtime.

- Customization and Flexibility: 3D printing allows for the production of custom parts and design modifications to improve performance.

- Solving Obsolete Part Issues: We help clients overcome the challenges of maintaining aging equipment by providing on-demand access to replacement parts.

Why Choose Omni3D’s 3D Printing Services?

Omni3D is committed to making additive manufacturing a viable alternative to traditional production methods. Our industrial-grade 3D printers and experienced team enable us to tackle even the most challenging projects. We specialize in:

- Industrial 3D Printing Solutions: Providing high-quality 3D printed parts for various industries.

- On-Demand Manufacturing: Responding quickly to emergency situations and production needs.

- Reverse Engineering and Design: Creating 3D models from existing parts or specifications.

- Material Expertise: Offering a wide range of materials, including PET-G, ABS, PA, and high-performance polymers.

- B2B 3D Printing Services: Tailoring our services to meet the specific needs of businesses.

Contact Us:

If you’re facing challenges with obsolete parts or seeking to improve your production flexibility, contact Omni3D team today at printroom@omni3d.com.

Let us show you how our 3D printing services can help you reduce costs and maximize efficiency.