Learn how the Omni TECH industrial 3D printer helps maintenance engineers eliminate vendor lock-in, reduce spare parts lead times from 8 weeks to 3 days, and achieve ROI in the first year.

Every maintenance engineer knows the scenario: a critical component on a 10-year-old machine fails. You contact the Original Equipment Manufacturer (OEM), and the response is a standard “8-week lead time.”

For years, industrial plants had no alternative but to accept these delays. You were locked into OEM schedules, exorbitant express shipping fees, and the compounding costs of a halted production line. Today, the industrial 3D printing revolution has changed that equation. Manufacturing independence is no longer a concept—it is a tool standing in your production hall.

Key Takeaways: The Omni TECH Value Proposition

- Dimensional Accuracy: ±0.12% (min. ±0.12 mm) for mechanical tolerances.

- Material Versatility: 24 engineering-grade filaments (Carbon Fiber, Glass Fiber, Kevlar, ESD).

- Rapid ROI: Investment typically pays off within 2–3 major breakdown events.

- Operational Agility: Reduce spare part lead times by up to 90%.

The True Cost of Waiting: A Comparative Analysis

In a continuous production environment, the clock starts ticking the moment a breakdown occurs. Here is how Omni TECH compares to traditional OEM procurement:

The Traditional OEM Route (High Risk)

- Initial Response: “Checking availability/backordered.”

- Average Lead Time: 4–8 weeks.

- Financial Impact: [Cost of Part] + [Hours of Downtime × Hourly Line Rate].

- The Result: Thousands in lost productivity and high-stress procurement cycles.

The Omni TECH Route (Agile Manufacturing)

- Initial Response: Load the digital twin and initiate printing.

- Scanning/Modelling: 1–2 days.

- Printing: 4–48 hours (geometry dependent).

- Post-processing: 1 day.

- Total Time to Recovery: 3–7 days.

Engineering Materials for Functional Spare Parts

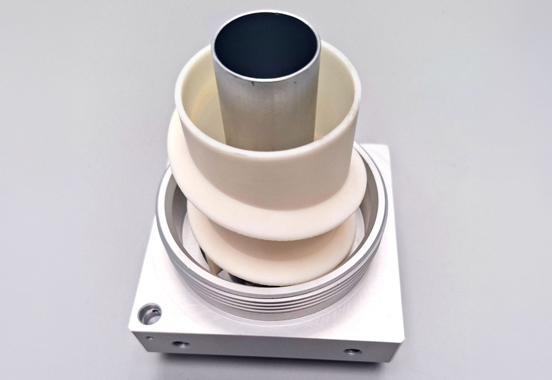

The Omni TECH is specifically designed for functional, end-use industrial components. To meet the rigorous demands of the shop floor, we support 24 industrial-grade materials, categorized by their mechanical properties:

1. Fiber-Reinforced (High Stiffness & Strength)

- PA-12 CF (Carbon Fiber): Offers stiffness comparable to aluminum; ideal for structural brackets.

- ASA-CF / ABS Carbon: High dimensional stability with added UV resistance for outdoor or industrial lighting environments.

- GF30-PA6 (30% Glass Fiber): Exceptional thermal resistance for parts near heat-generating machinery.

2. Impact & Abrasion Resistance (Aramid/Kevlar)

- ABS/ASA Kevlar: High impact strength and superior abrasion resistance for guides, rollers, and protective housings.

3. Specialized & Technical Applications

- ABS ESD: Vital for electronics manufacturing to prevent electrostatic discharge.

- ALFATEICO (PPS): High-temperature resistance for specialized industrial chemical environments.

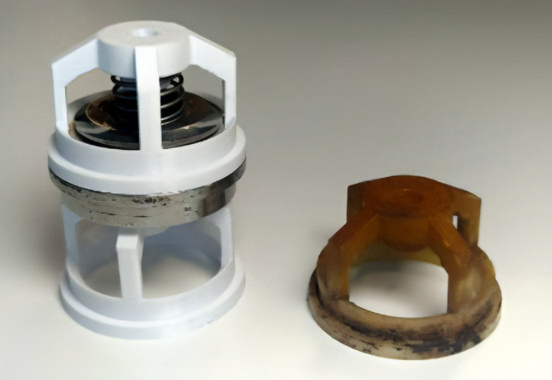

- TPU-85A / 93A: Flexible materials for custom gaskets, seals, and vibration dampeners.

Calculating Your ROI: When Does 3D Printing Pay Off?

For a maintenance department, the ROI of the Omni TECH is a matter of simple industrial math. Evaluate your facility based on these three metrics:

- Frequency: How many times per year does unplanned downtime occur due to obsolete or out-of-stock parts?

- Downtime Value: What is the real-time cost of one hour of inactivity on your primary production line?

- Procurement Premiums: How much do you spend annually on “express” OEM markups and international shipping?

In most high-utilization environments, the Omni TECH pays for itself within the first 12 months—often saving the company more than the cost of the machine during a single major breakdown.

Is Your Facility Ready for Manufacturing Independence?

The Omni TECH is an industrial workhorse, but it is important to understand its ideal applications:

- Aging Machine Parks: Perfect for equipment where the OEM no longer supports legacy parts.

- Continuous Production: Essential for 24/7 operations where every hour of downtime is a significant loss.

- Digital Inventory: Enables the transition to an Industry 4.0 Digital Warehouse, reducing physical storage costs.

Engineering Transparency: The Limits

- Extreme Thermal Loads: For parts operating consistently above 250°C, the Omni PRO HT (PEEK/PEKK capable) is required.

- Sub-0.1mm Precision: While our ±0.12% accuracy covers 80% of parts, ultra-critical tolerances may still require CNC finishing.

Start Your Technical Audit Today

Vendor lock-in ends when you control your production schedule. To verify if the Omni TECH is the right fit for your plant, our engineering team is ready to conduct a technical feasibility study.

Contact Omni3D with the following details:

- Part Samples: A list or 3D files of your most frequent OEM orders.

- Environment: Operating temperatures, mechanical loads, and chemical exposures.

- Cost Baseline: Your current average lead times and procurement costs.

Schedule a technical consultation with Omni3D to optimize your downtime cost equation.

#Industrial3DPrinting #MaintenanceEngineering #MRO #OmniTECH #DowntimeReduction #Industry40 #SpareParts #ManufacturingIndependence #3DPrintingROI