Chamber Temperature’s Impact on Strength in material extrusion

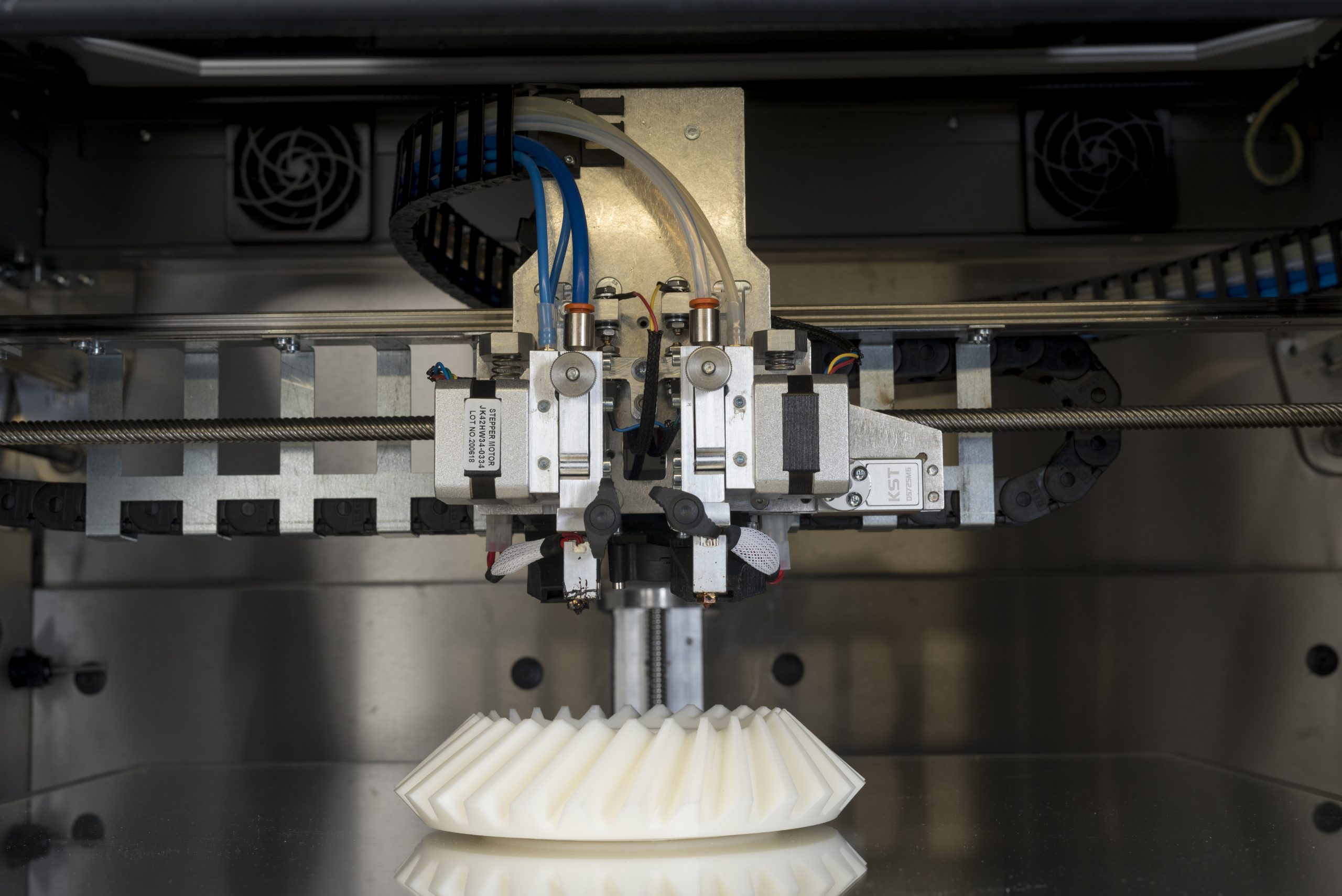

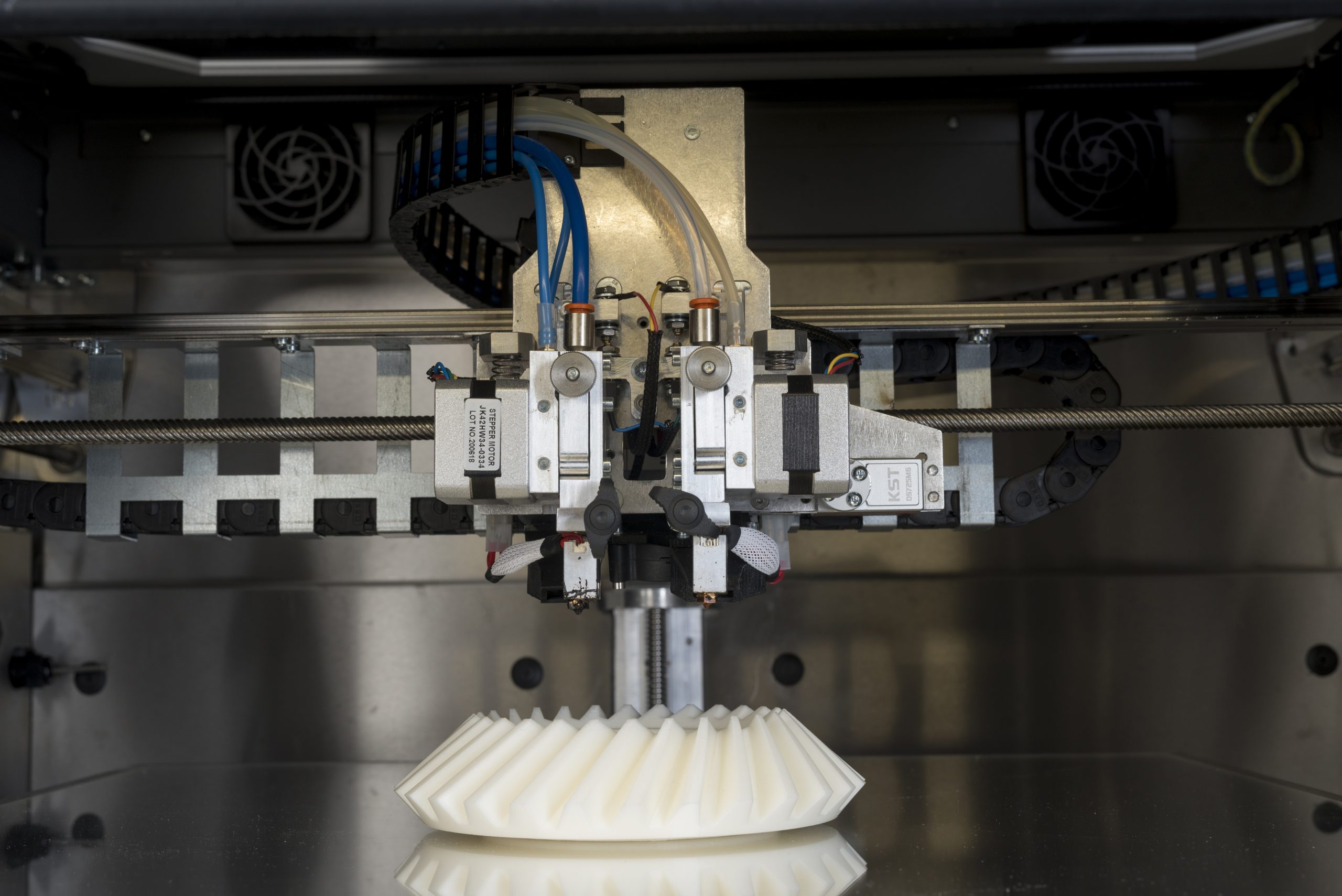

Achieving optimal part quality in additive manufacturing material extrusion often hinges on factors beyond mere geometry and material selection. One such critical aspect is the controlled thermal environment provided by heated chambers, particularly when working with advanced materials like super polymers.

Large-Format, Heated Chambers: The Cornerstone of Defense-Grade 3D Printing

Reliability and performance are paramount in defense and 3D printing has emerged as a transformative technology. The successful implementation of this technology hinges on several critical factors, with chamber size and temperature control standing out as particularly crucial to blend 3D printing into established manufacturing processes.

Material Matters: Choosing the Right Filament for Defense Applications

When it comes to 3D printing for defense applications, material selection is paramount. The ability to choose the right filament is crucial for producing parts that meet the stringent requirements of military operations and lasts.

Maximizing 3D Printing Success: The Key to Drying Filament for High-Temperature Polymers

Welcome to our blog! In this post, we will delve into a crucial aspect of achieving optimal results in material extrusion 3D printing: the importance of drying filament, especially when working with engineering high-temperature polymers. We will explore the benefits of filament drying and share valuable insights on how to reduce costs along the way.

Soaring to New Heights: Material Extrusion takes Flight in Aerospace Applications

Building upon our commitment to safety-first innovation in regulated markets, Omni3D’s industrial extrusion 3D printing technology is taking flight in the demanding world of aerospace. This blog entry, a continuation of our exploration of 3D printing within highly regulated industries, dives deeper into the specific considerations and exciting possibilities for large-format material extrusion within the aerospace sector.