Case study: SUPERQUAD SLOVAKIA s.r.o. (Automotive)

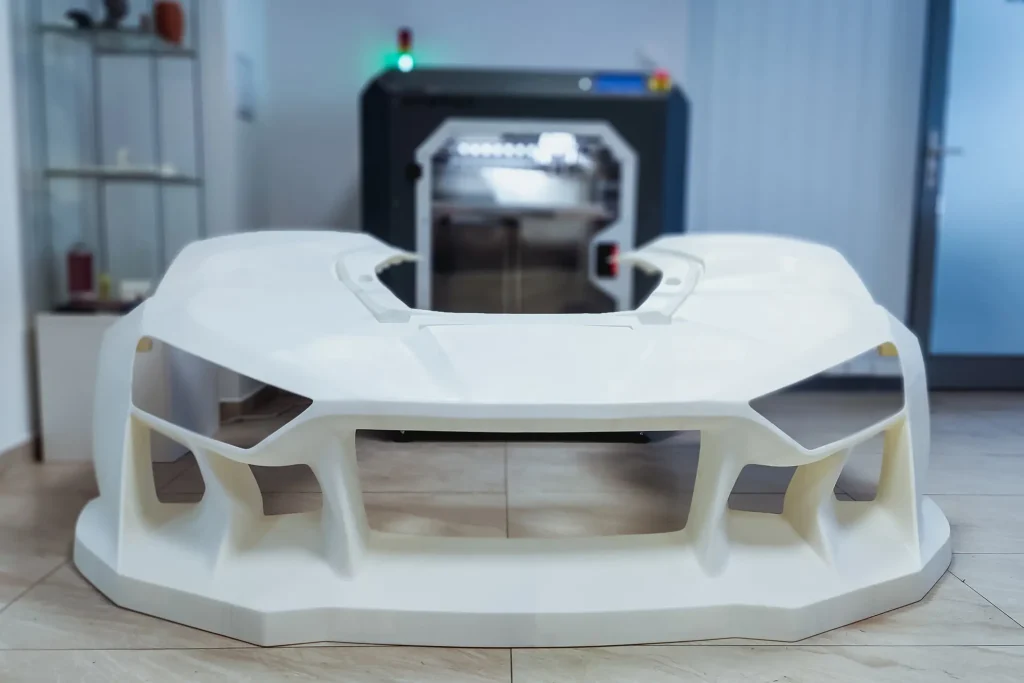

A common bottleneck in automotive prototyping is dependency on external suppliers, especially when parts must be produced fast, iterated, and tested under real conditions. This case study shows how a 3D printed car body prototype helped reduce that dependency by producing a large-format part in-house, with controlled lead time and material selection.

Source note: This article is based strictly on the information provided in the attached case study PDF.

Print specifications:

- Industry: Automotive

- Sector: Car Production

- Client: SUPERQUAD SLOVAKIA s.r.o.

- Category: Prototyping / Modeling

- Filament: PC-ABS

- Printing time: 690 hours

- Weight: 30 kg

Challenge: a full-scale body element, printed fast and at low cost

The customer requested a full body element for a SuperQuad model in 1:1 scale. The requirements were clear:

- the part should be printed fast and with low cost,

- it should be strong and relatively impact-resistant, and

- the chosen approach should create a convincing case for implementing 3D printing in the production process.

The case study emphasizes that meeting these goals requires balancing speed, cost, and mechanical performance, starting with the right material choice.

Material choice: why PC-ABS was selected

The client chose PC-ABS because it is:

- reliable,

- strong,

- resistant to impacts,

- hard enough for the intended use,

- and relatively easy to print.

This material choice was positioned as the foundation for producing a large-format part that could withstand handling and early-stage testing expectations.

Printing approach: controlling shrinkage and complexity at large scale

To produce the parts, the Omni3D team used the Factory 2.0 NET, which is equipped with:

- an active heated chamber (Omni3D Air Circulation),

- an Omni3D Cooling System,

- capability for better shrinkage control,

- full infill printing,

- handling complicated geometry, and

- the ability to use two heads and print with efficient support material.

In the case of large parts, controlling shrinkage and warping is often the key limitation. The printer configuration is a crucial factor in achieving stability and consistency.

Outcome: requirements met + next validation steps planned

The print was tested by the client and also tested to assess the technological limits of the machine. The printed parts will be used in a car prototype.

Technical summary table

| Item | Value |

|---|---|

| Client | SUPERQUAD SLOVAKIA s.r.o. |

| Industry / sector | Automotive / Car Production |

| Use case | Prototyping / Modeling |

| Part | Full body element (1:1 scale) |

| Material | PC-ABS |

| Printer | Factory 2.0 NET |

| Process highlights | Heated chamber (Air Circulation), Cooling System, shrinkage control, full infill, complex geometry, dual-head capability, efficient support material |

| Print time | 690 h |

| Weight | 30 kg |

Practical takeaways (for automotive prototyping teams)

- Large-format 3D printing reduces supplier dependency for early-stage prototypes where speed and iteration matter more than traditional tooling.

- Material selection is the first “business case” lever: impact resistance + print reliability supports faster decision cycles.

- Shrinkage control is critical for big parts; chamber management and cooling strategy can determine whether a prototype is usable.

- Prototype validation is staged: print → finish → reinforcement (carbon fiber) → vehicle testing → approval pathway.

FAQ

What was the goal of this 3D printed car body project?

To produce a full-scale (1:1) body element quickly and at low cost, while remaining strong and impact-resistant enough to justify adopting 3D printing in the production process.

Why was PC-ABS used?

PC-ABS as reliable, strong, impact-resistant, hard enough for the application, and relatively easy to print.

What machine was used?

Factory 2.0 NET, with an active heated chamber (Omni3D Air Circulation) and Omni3D Cooling System, supporting shrinkage control, full infill, complex geometry, and dual-head printing.

What were the print time and weight?

690 hours total printing time and 30 kg final weight.

What happened after printing?

The printed body element was tested and met customer requirements. The next planned steps include carbon fiber reinforcement and testing in a prototype car.