by admin | Oct 15, 2020 | Knowledge

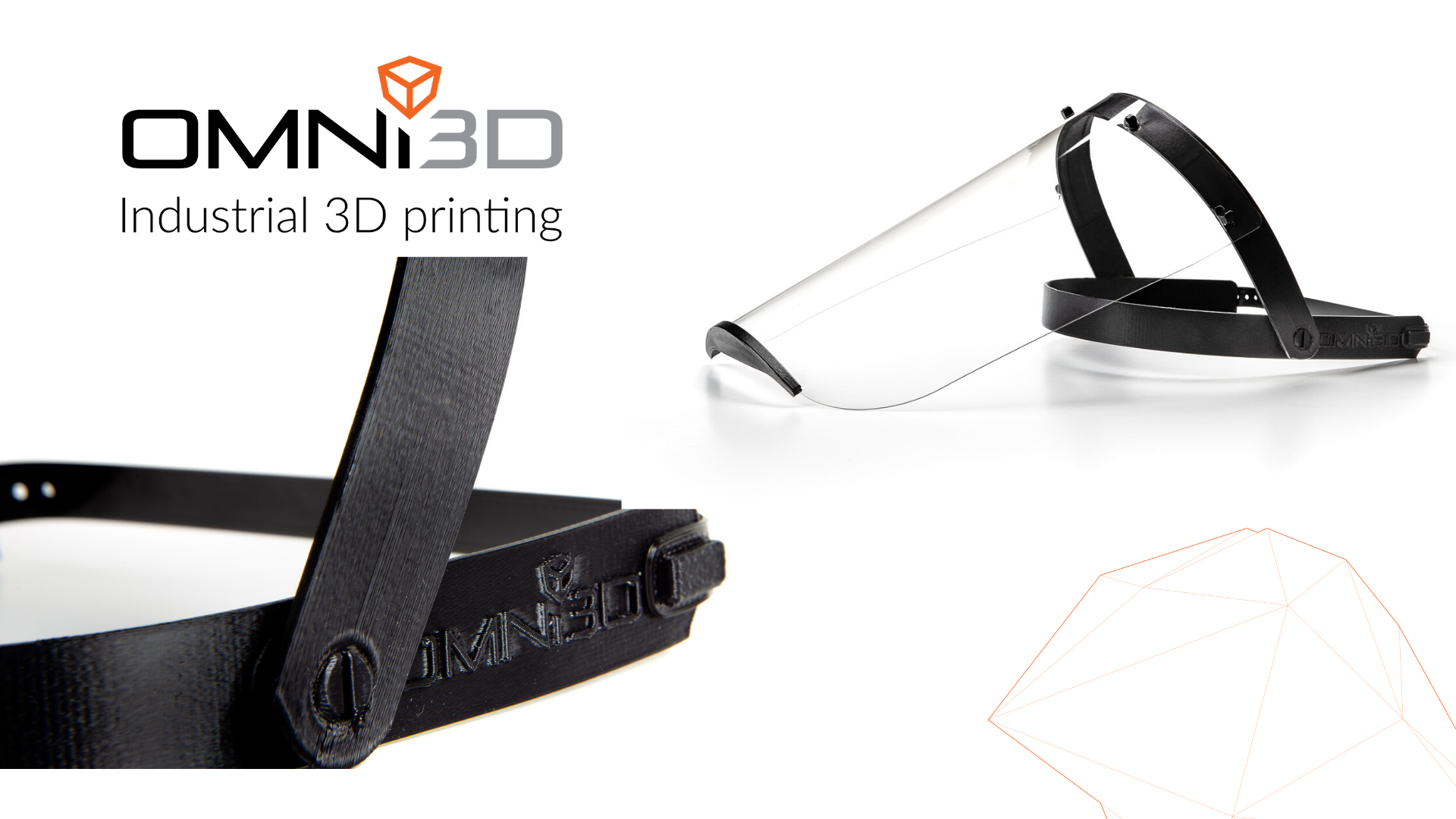

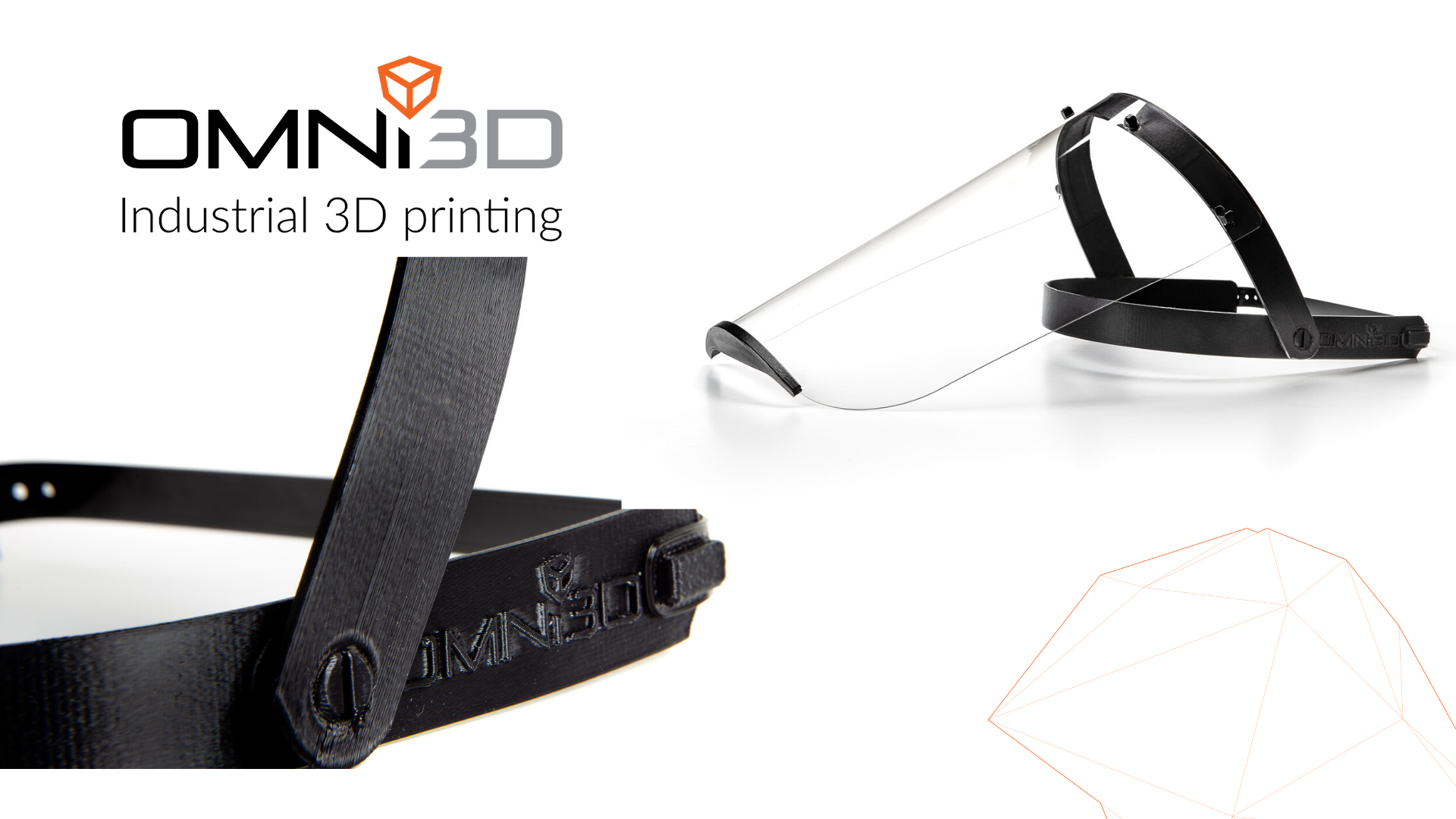

Designed in cooperation with doctors, the improved face shields provides high wearing comfort thanks to the adjustable and lifted visor. Thanks to the use of high quality materials, it can be disinfected entirely with standard agents.

by admin | Oct 1, 2020 | Knowledge

The 3D printing technology gives a wide range of possibilities to produce elements, spare parts and tools used in the maintenance area. 3D printers can make even the most non-standard and difficult to access elements in a short time, thus saving time and production costs.

by admin | Sep 24, 2020 | Knowledge

Companies from the railway industry began to implement 3D printing technologies to perform production and maintenance work. Building a good train that can withstand the distance and provide passengers with comfort requires a large number of very high quality components. The rail sector is increasingly turning to additive manufacturing, more commonly known as 3D printing. Railroad companies and analysts say the technology – which has been in development over the last three decades – can help bring obsolete spare parts to market and cut production times by up to 95%. How effective is this technology and how much does it support the industry?

by admin | Sep 17, 2020 | Knowledge

It’s been a long time since Frank Pearne and Charles L. Krum started working on a printing telegraph called a teletype. Since that invention, technology has taken a significant step forward, making electric cars, super fast computers or space travel a reality. Additive technology, known to us perfectly well as 3D printing, has been developing for about two decades, but its role in the ongoing technological revolution is significant.

by admin | Sep 15, 2020 | Knowledge

Conveniently preparing and starting the printout on a 3D printer, the ability to monitor and make changes to the print progress and share projects with your team – these are just some of the possibilities offered by integrating the camera and managing the Omni500 LITE printer remotely.

by admin | Sep 8, 2020 | Knowledge

The FFF (Fused Filament Fabrication) or FDM (Fused Deposiotion Modeling) technology is a versatile 3D printing technique, whose characteristic feature is the extrusion of material in the form of a thick vein – a filament from the printing heads. Ease of use, optimal cost of implementation and durability of printouts make this 3D printing technology very popular in industrial applications.