ADDITIVE MANUFACTURING FOR DEFENSE INDUSTRY

On-Demand, Robust & Secure Part Production: Omni3D’s Industrial-Grade Large-Format Printers Ensure Reliable Manufacturing of Mission-Critical Components with Traceability and Material Versatility for Demanding Defense Applications.

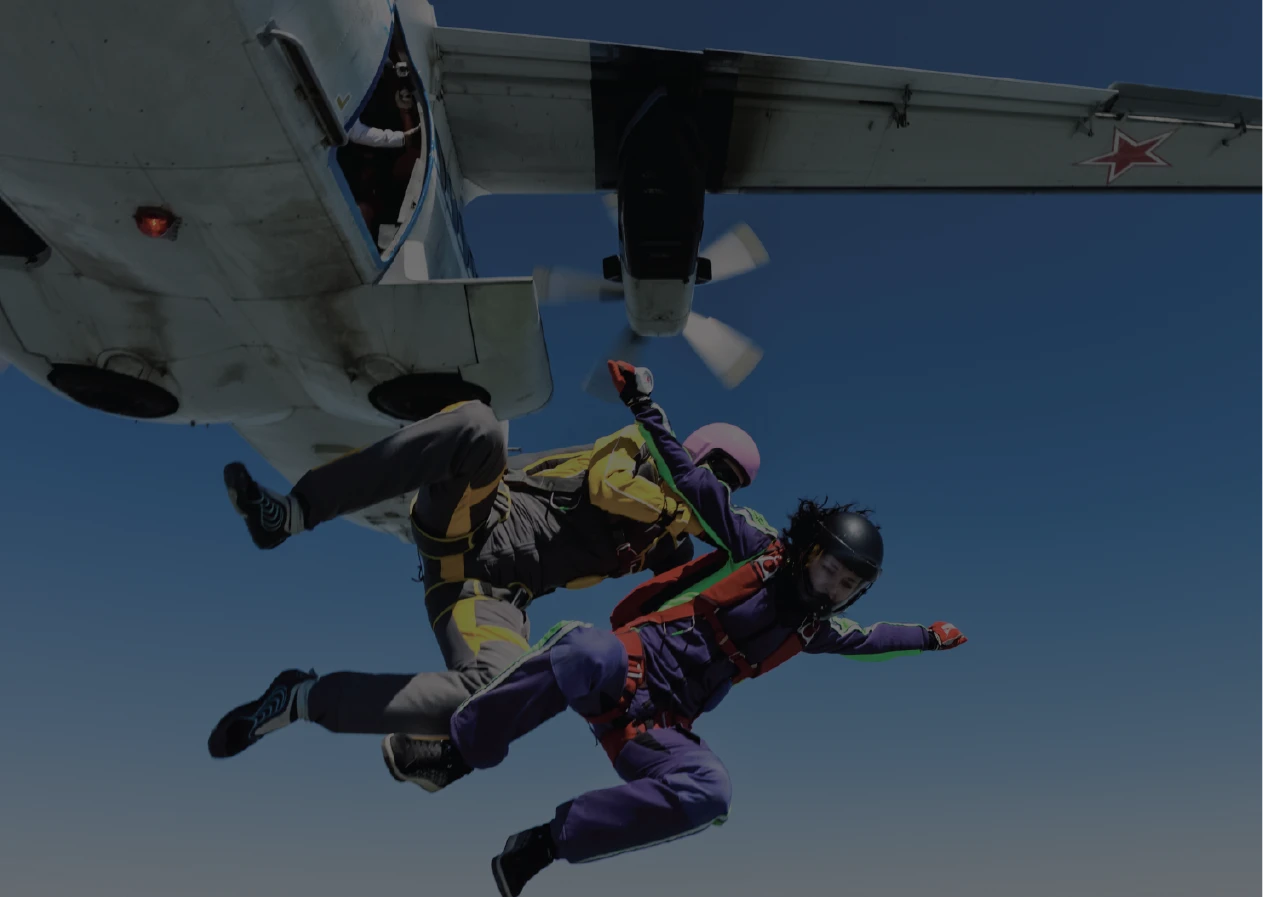

FAST RESPONSE WITH ADDITIVE MANUFACTURING ON THE BATTLEFIELD & R&D PROJECTS

3D printing technology offers unbeatable faster responses and a revolutionary approach to battlefield critical situations, empowering military forces with the ability to produce essential parts on-demand or test new solutions.

Partner to leading companies

Airbus, a global leader in aerospace, leverages Omni3D’s large-format 3D printing to accelerate the production of tooling and fixtures for aircraft manufacturing.

Collins Aerospace, a key supplier of aerospace and defense technologies, utilizes Omni3D’s open material platform to manufacture high-precision jigs.

Leonardo Helicopters, a major player in the rotorcraft industry, relies on Omni3D’s industrial-grade 3D printing systems to produce custom jigs and fixtures for helicopter assembly.

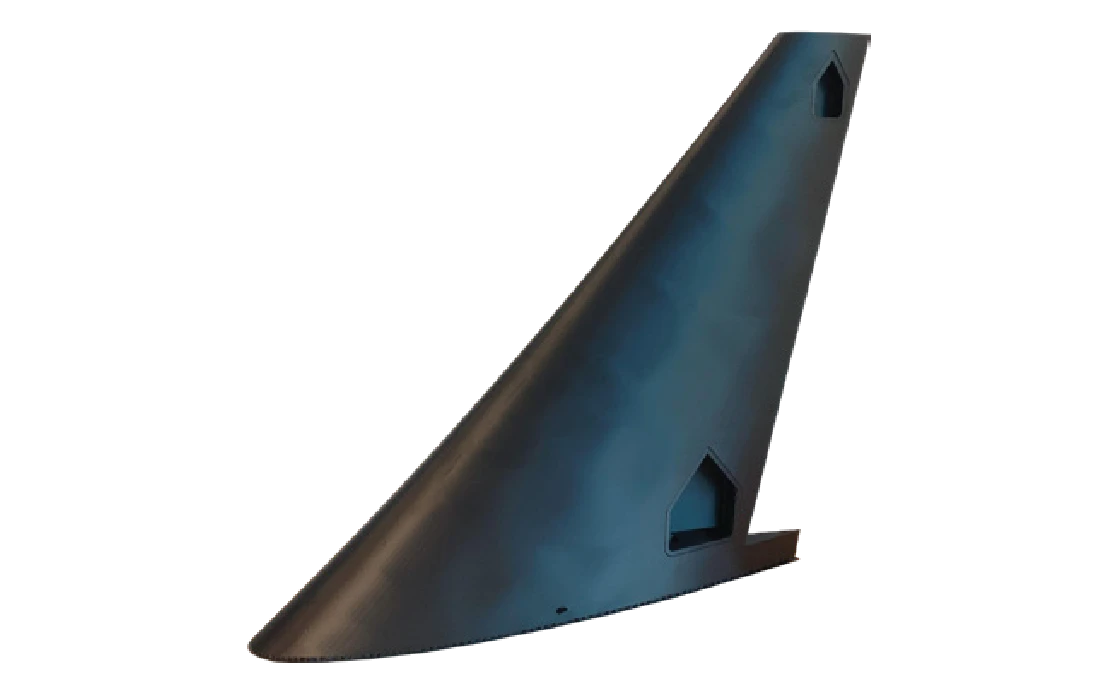

The Lukasiewicz Research Network – Institute of Aviation, a leading research and development center for the Polish aerospace industry, employs Omni3D’s 3D printing technology to conduct cutting-edge research in aerodynamics.

Safran Helicopters, a world leader in helicopter manufacturing, utilizes Omni3D’s large-format 3D printing to produce spare parts and tooling for helicopter maintenance and repair.

Symétrie, a specialist in high-precision positioning systems for aerospace and defense, leverages Omni3D’s 3D printing technology to manufacture complex components for their hexapod.

application cases

Parachute Security Knife

Functional end-use parts

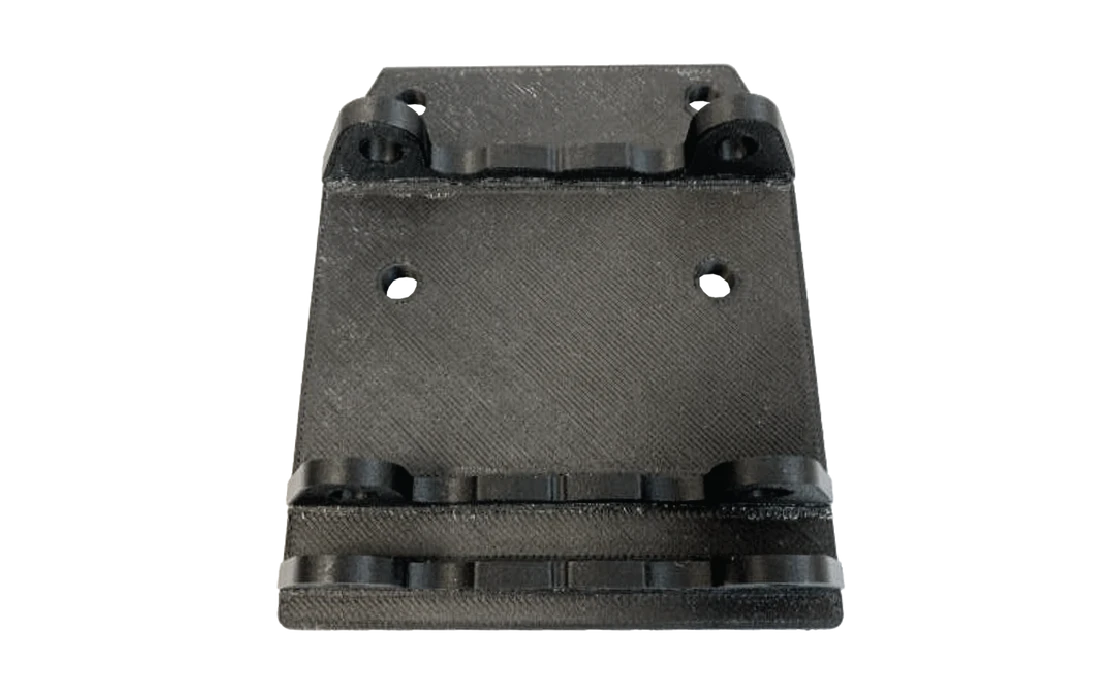

Hexapods large parts

FUNCTIONAL END-USE PARTS

Coverage for lower leg prosthesis

low volume manufacturing

3d printers for defense

OmniPRO |

OmniTECH |

OmniLITE |

|

|---|---|---|---|

| Build size | 500 × 500 × 500 mm | 500 × 500 × 570 mm | 460 × 460 × 560 mm |

| MAX. HEAD TEMPERATURE | 500°C | 420°C | 360°C |

| Max Chamber temperature | 220 °C (ACTIVELY HEATED) | 70 °C (ACTIVELY HEATED) | 50 °C (PASSIVELY HEATED) |

| BUILT-IN FILAMENT DRYER | YES | NO | NO |

| Brochure | Download | Download | Download |

Materials

At Omni3D, we believe in the power of choice. Our open material systems allow you to explore a vast array of materials, tailored to your specific needs. From engineering-grade thermoplastics to specialty filaments, our printers are designed to handle it all.

Omni compatible materials include:

TPU

ASA

Parachute Safety Knife

CF PA-12

JELCZ 442.32 air conditioner bracket

ABS

PEKK

Industrial 3D printing solutions trusted by