The Problem

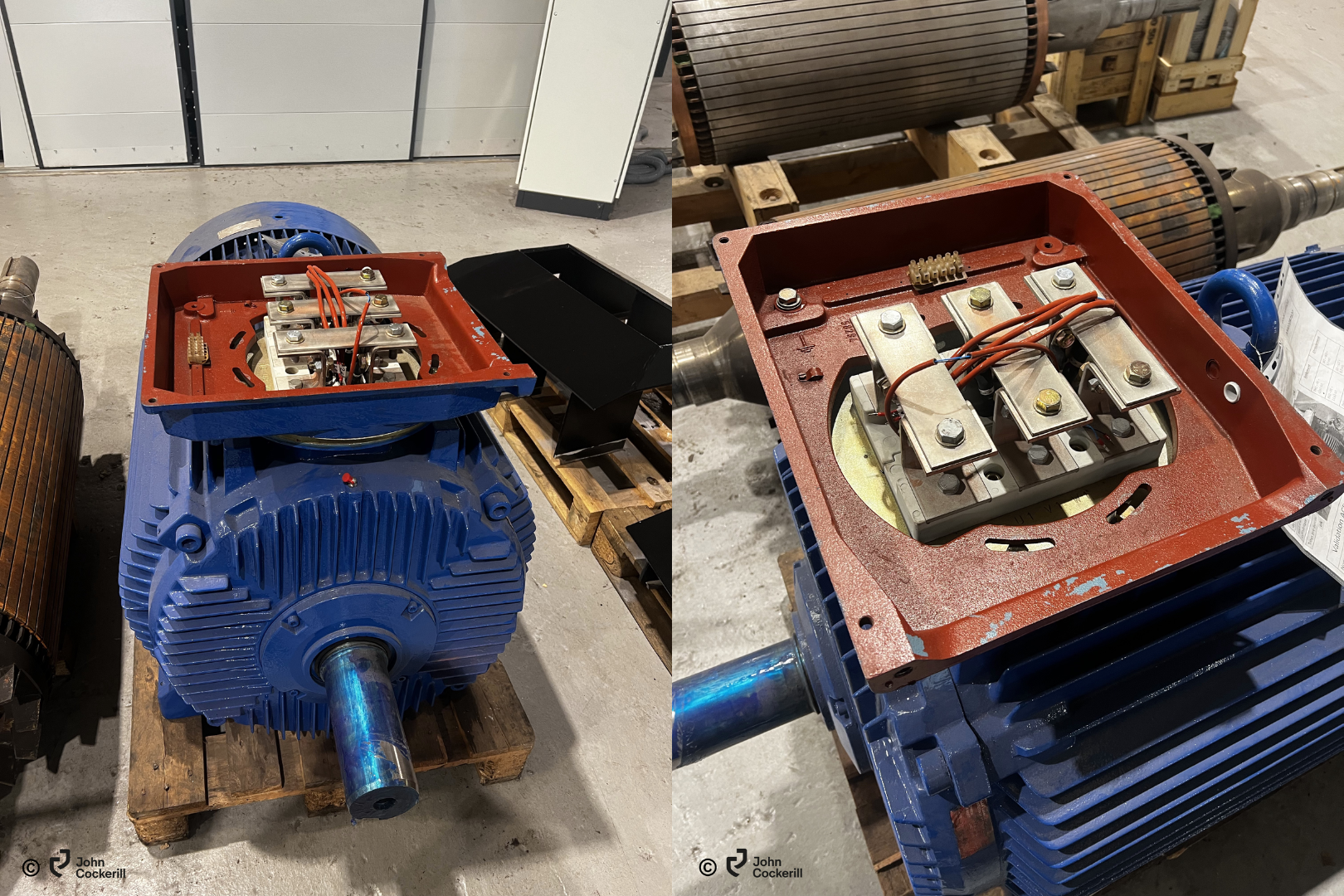

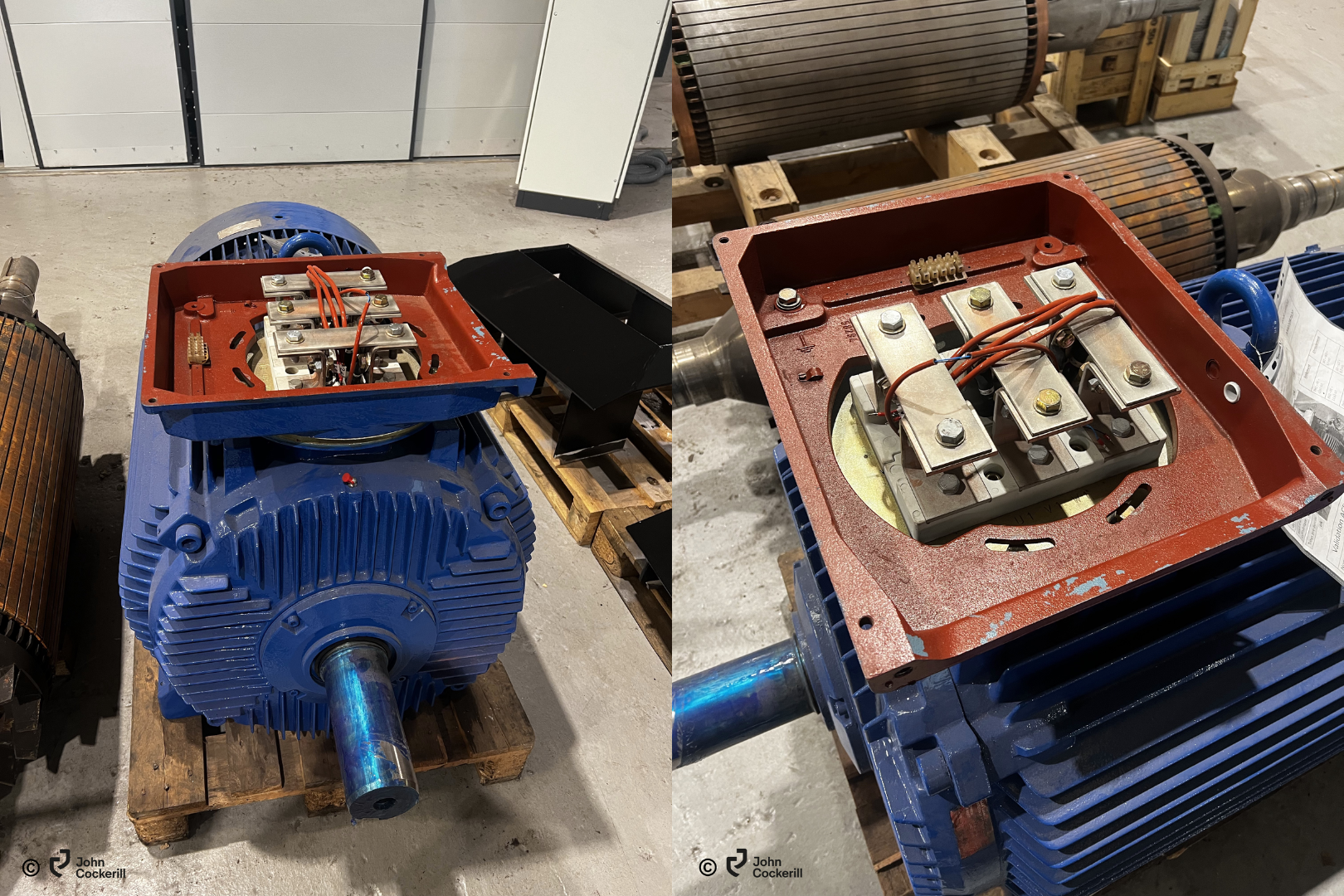

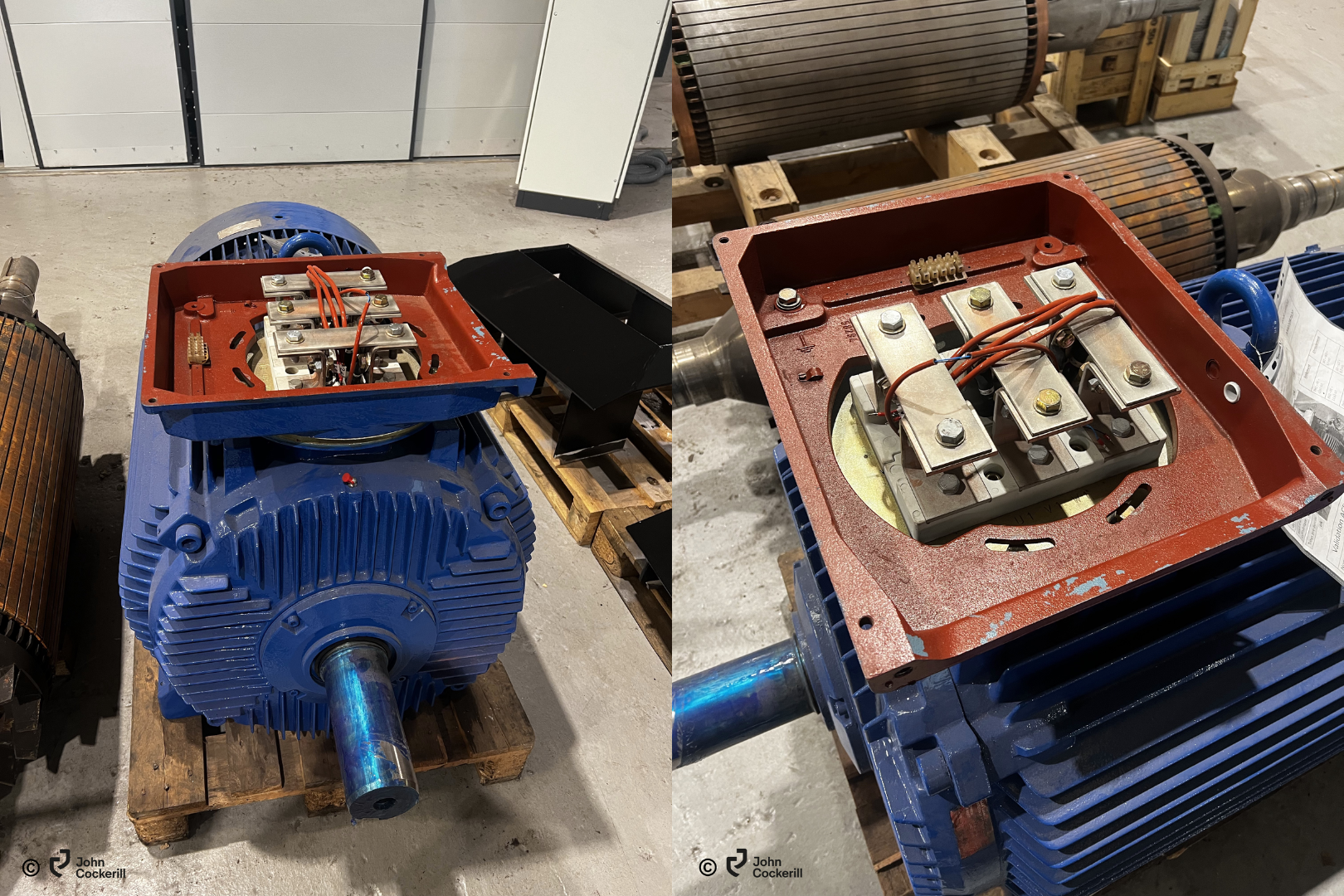

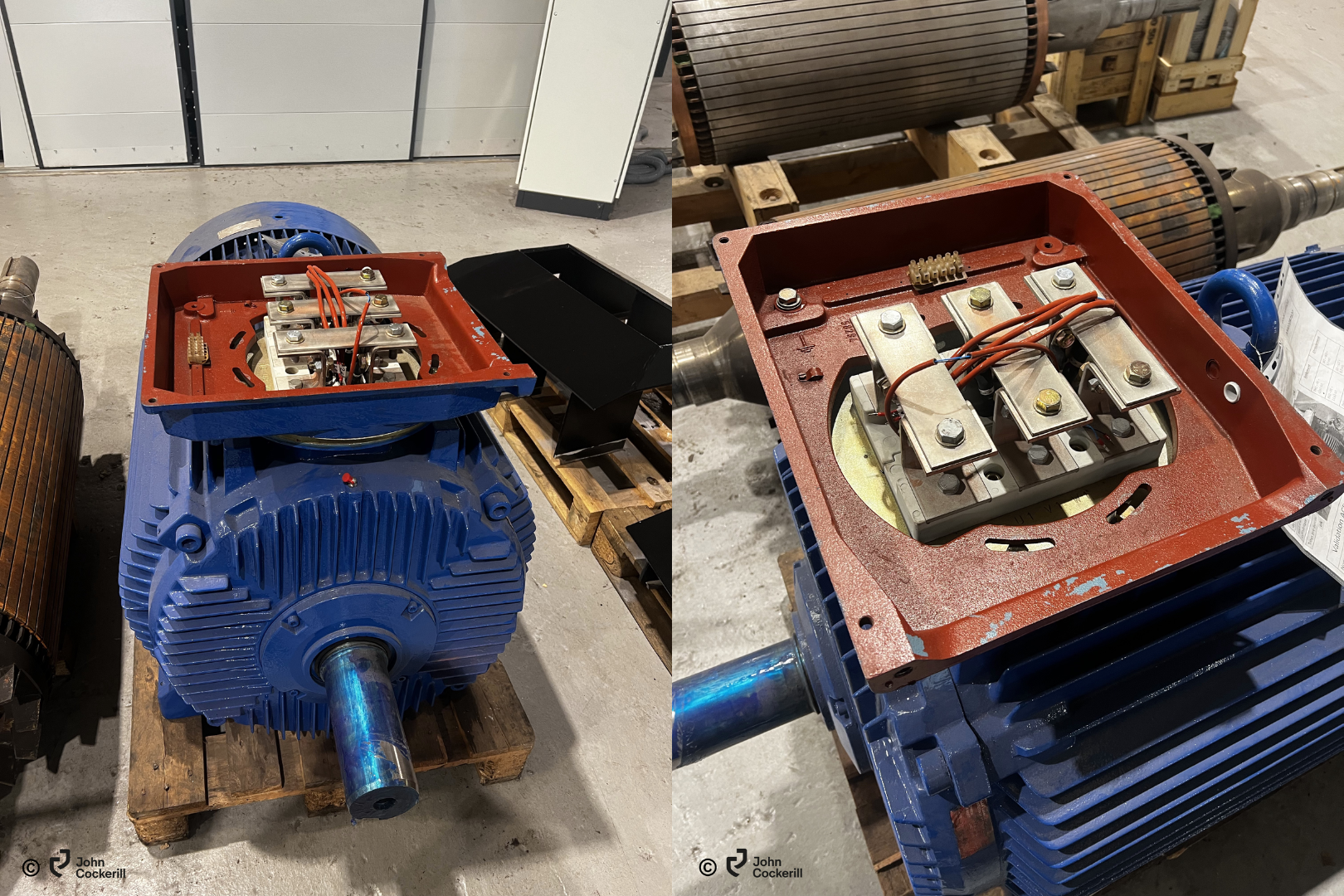

John Cockerill Services faced a time-sensitive repair for a 200kW electric motor in the steel industry. The crucial terminal box cover was missing, leaving motor terminals exposed.

Traditional Challenges

- Lead time: Sourcing a custom injection-molded cover would incur significant cost and extended lead times, hindering repair progress.

- Cost: For a single, unique part, traditional manufacturing methods are often cost-prohibitive.

- Material limitations: Finding a material suitable for the cover’s size and application could be challenging with conventional methods.

The Solution: print big parts in engineering materials

Leveraging their in-house Incremental Manufacturing department, John Cockerill Services turned to large-format FDM 3D printing with the Omni 500 LITE printer.

Omni3D FDM technology offered:

- Rapid high-quality prototyping: A PLA prototype cover was designed and printed within 10 hours (design) +33 hours (printing), enabling quick visualization and iteration.

- Cost-effectiveness: 3D printing proved more cost-efficient than traditional manufacturing methods for a single, custom part.

- Material versatility: ABS ESD material offered the necessary strength, durability, and static dissipation properties for the large cover (410 x 480 x 120 mm).

The Results:

- Reduced downtime: The final ABS ESD cover was printed in 145 hours, significantly faster than traditional methods, minimizing repair delays.

- Cost savings: Compared to injection molding, 3D printing delivered cost advantages for this unique part.

- Improved efficiency: The success of this project led John Cockerill Services to adopt 3D printing as a manufacturing option for similar large-format replacements, streamlining their repair process.

Benefits for the Railway and Industrial Maintenance B2B Audience:

- Reduced downtime: Minimize aircraft groundings and production delays with rapid parts manufacturing.

- Cost optimization: Produce custom, low-volume parts cost-effectively compared to traditional methods.

- Inventory optimization: Reduce reliance on stocked spare parts with on-demand printing capabilities.

- Complex geometries: Create intricate parts with challenging designs impossible with conventional methods.

Upgrade your maintenance service offer with Omni3D’s large-format industrial FDM 3D printing solutions. ️

- Contact us today for a free consultation. ✅

- Discover how 3D printing can optimize your business.

- See real-world case studies of successful implementations.