ADDITIVE MANUFACTURING FOR MANUFACTURING INDUSTRY

Scalable & Cost-Effective Production: Omni3D’s Large-Format Industrial Printers Deliver High-Volume, Customizable Manufacturing Solutions with Engineering-Grade Materials.

Transform Your Manufacturing Floor with Industrial 3D Printing.

Omni3D empowers manufacturers to optimize production processes, reduce costs, and accelerate innovation. Our large-format, open material systems enable the production of custom tooling, jigs, fixtures, and end-use parts with exceptional strength and durability, driving efficiency and competitiveness.

Partner to leading companies

Volkswagen is a German automotive giant and one of the world’s largest car manufacturers. Known for models like the Golf, Passat, and Tiguan, it emphasizes innovation, sustainability, and electric mobility while maintaining its reputation for quality and reliability.

BOSCH is a global leader in technology and engineering, specializing in automotive, industrial, and consumer electronics. With a strong focus on innovation, automation, and sustainability, the company develops cutting-edge solutions to enhance efficiency and reliability across various industries.

ARE is a leading company in robotics automation, designing and manufacturing advanced robotic systems for industrial applications. It focuses on enhancing production efficiency, safety, and precision through customized automation solutions tailored to modern manufacturing needs.

EBA is a specialized metal processing company known for its expertise in manufacturing high-precision components. It provides durable, high-quality metal solutions for various industries, integrating advanced production techniques to optimize efficiency and cost-effectiveness.

application cases

Compared to traditional manufacturing, 3D printing stands out by saving both time and costs. It allows for faster idea validation and streamlines decision-making. The flexibility of its materials enables more efficient tooling production and the creation of lighter, intricate components with reduced part counts.

Remote Control Housings

Low Volume Manufacturing

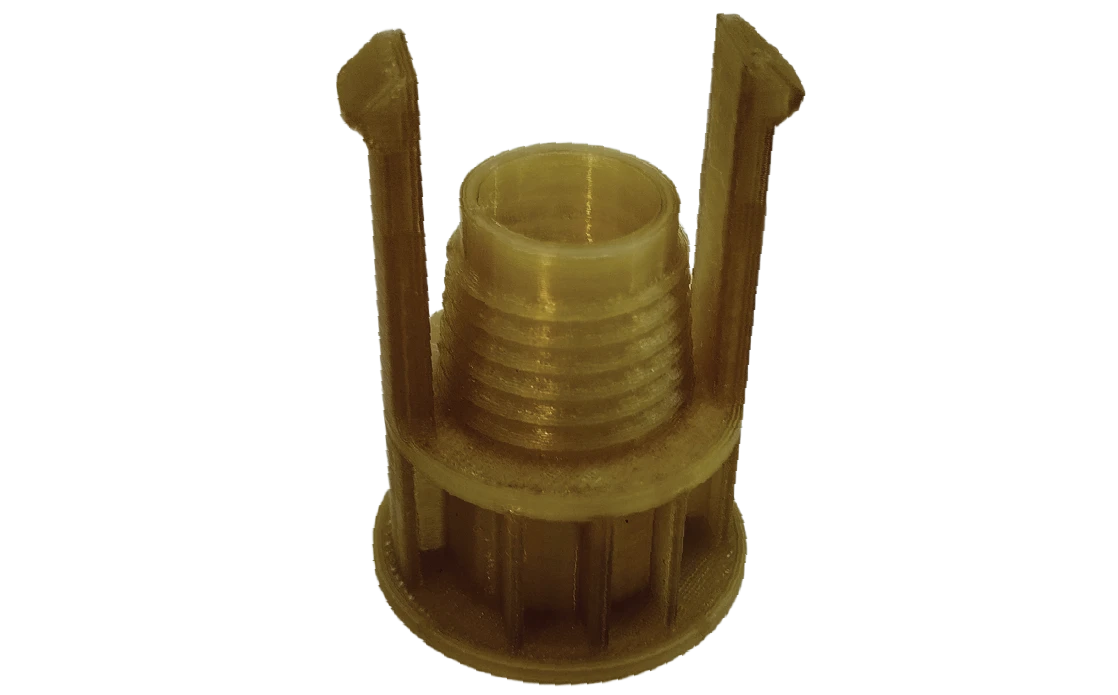

Check Gauge

Jigs & Tooling

Blister Transport tray

Prototyping

3d printers for Manufacturing

OmniPRO |

OmniTECH |

OmniLITE |

|

|---|---|---|---|

| Build size | 500 × 500 × 500 mm | 500 × 500 × 570 mm | 460 × 460 × 560 mm |

| MAX. HEAD TEMPERATURE | 500°C | 420°C | 360°C |

| Max Chamber temperature | 220 °C (ACTIVELY HEATED) | 70 °C (ACTIVELY HEATED) | 50 °C (PASSIVELY HEATED) |

| BUILT-IN FILAMENT DRYER | YES | NO | NO |

| Brochure | Download | Download | Download |

Materials

At Omni3D, we believe in the power of choice. Our open material systems allow you to explore a vast array of materials, tailored to your specific needs. From engineering-grade thermoplastics to specialty filaments, our printers are designed to handle it all.

Omni compatible materials include:

ABS

Custom siren casings

ABS

Custom tray for electronics

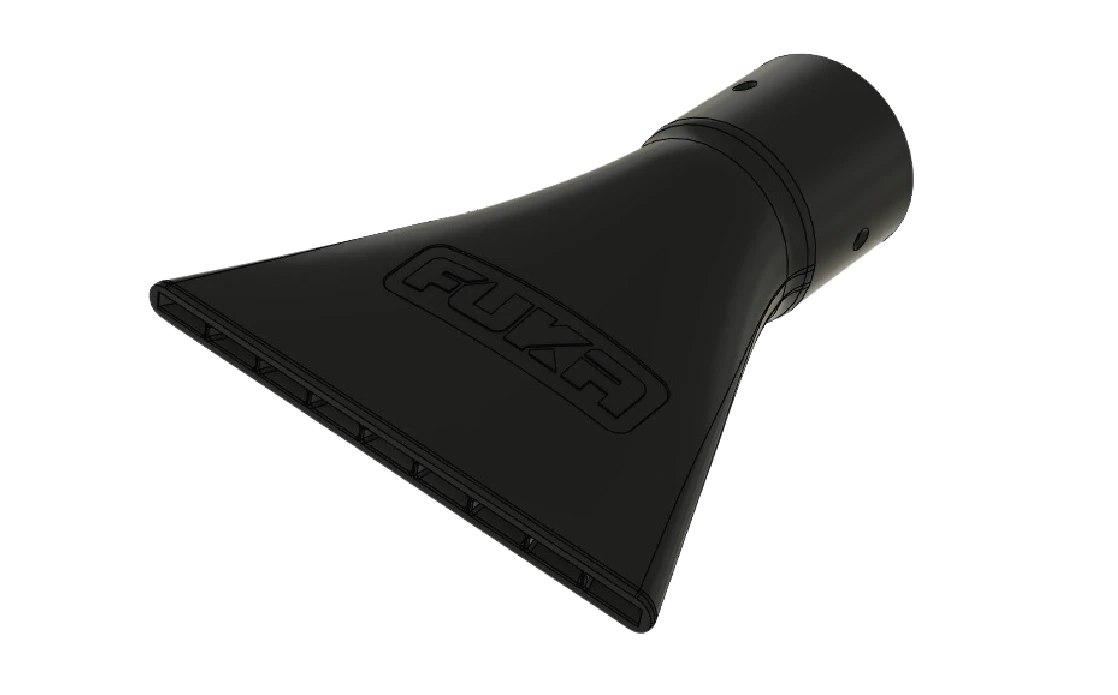

TPU-93

Flexible vacuum nozzles

ASA-39

Joint covers

PEKK

Window roller part

Our technology is trusted by