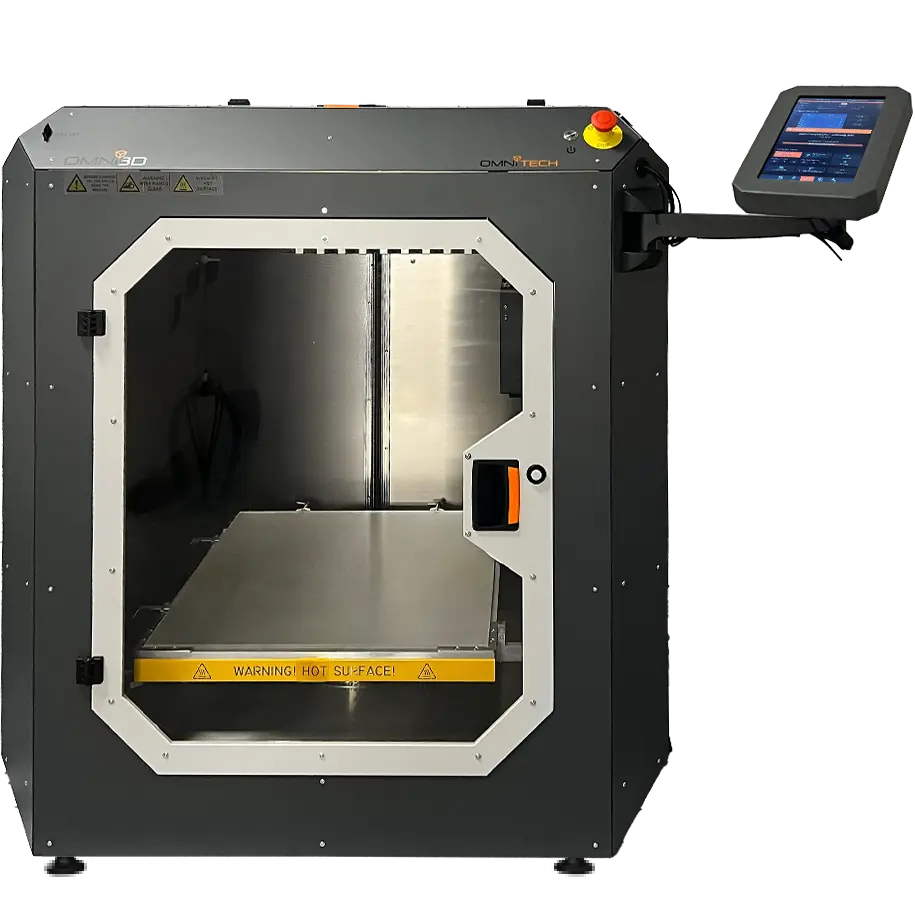

HIGH-PERFORMANCE

LARGE-FORMAT FUNCTIONAL PARTS

Industrial high-performance parts

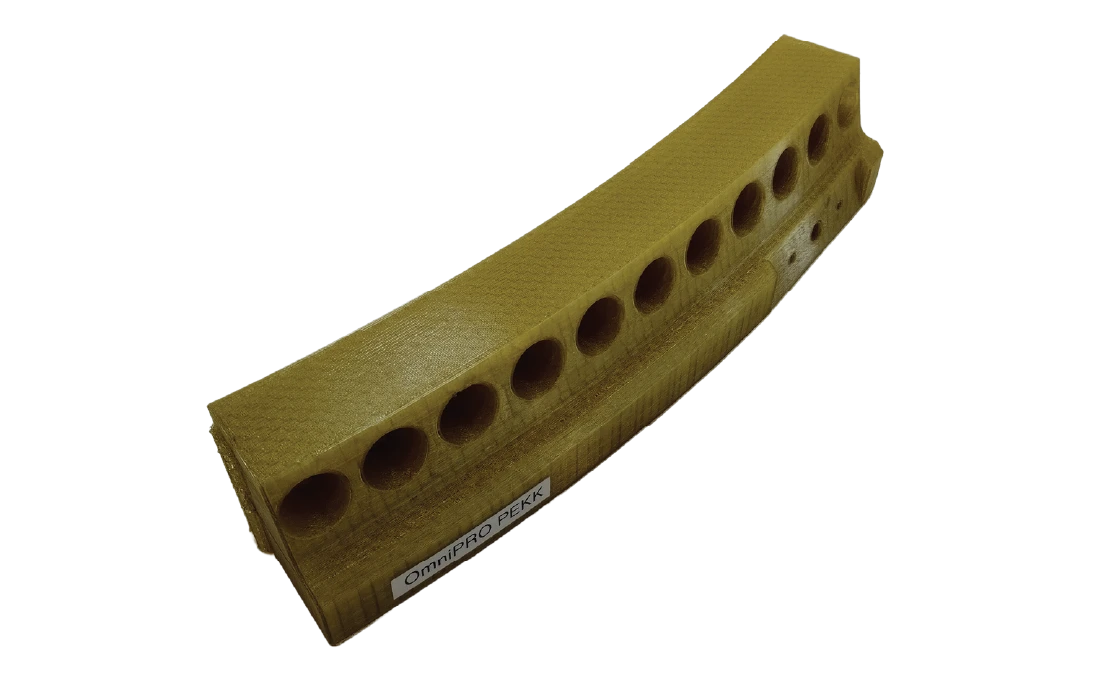

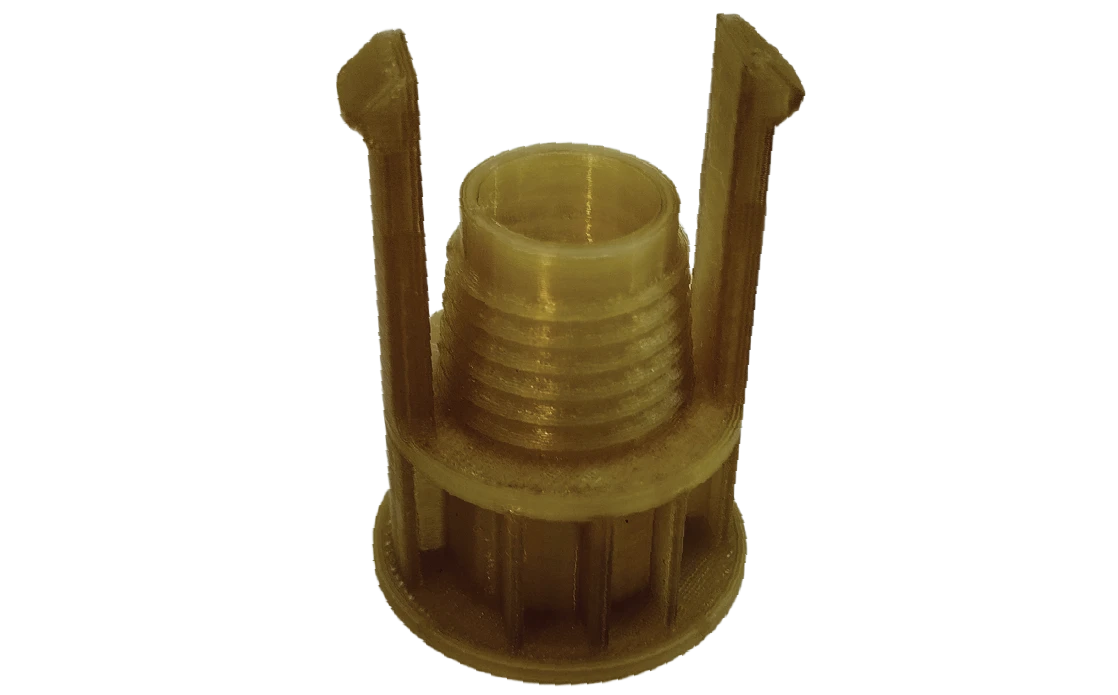

Strong, high-stress, HT, chemically resistant parts for a wide range of industries in PPS, GF-PPS, PEKK.

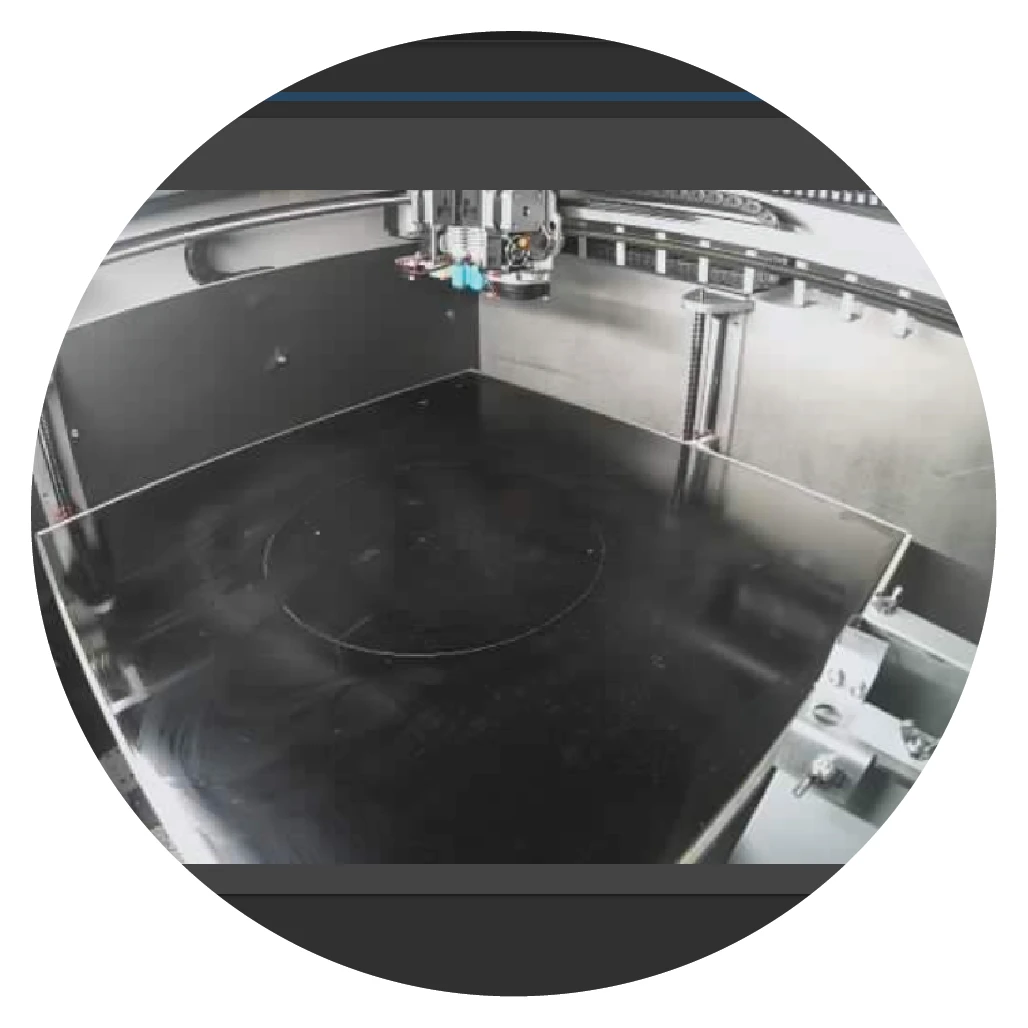

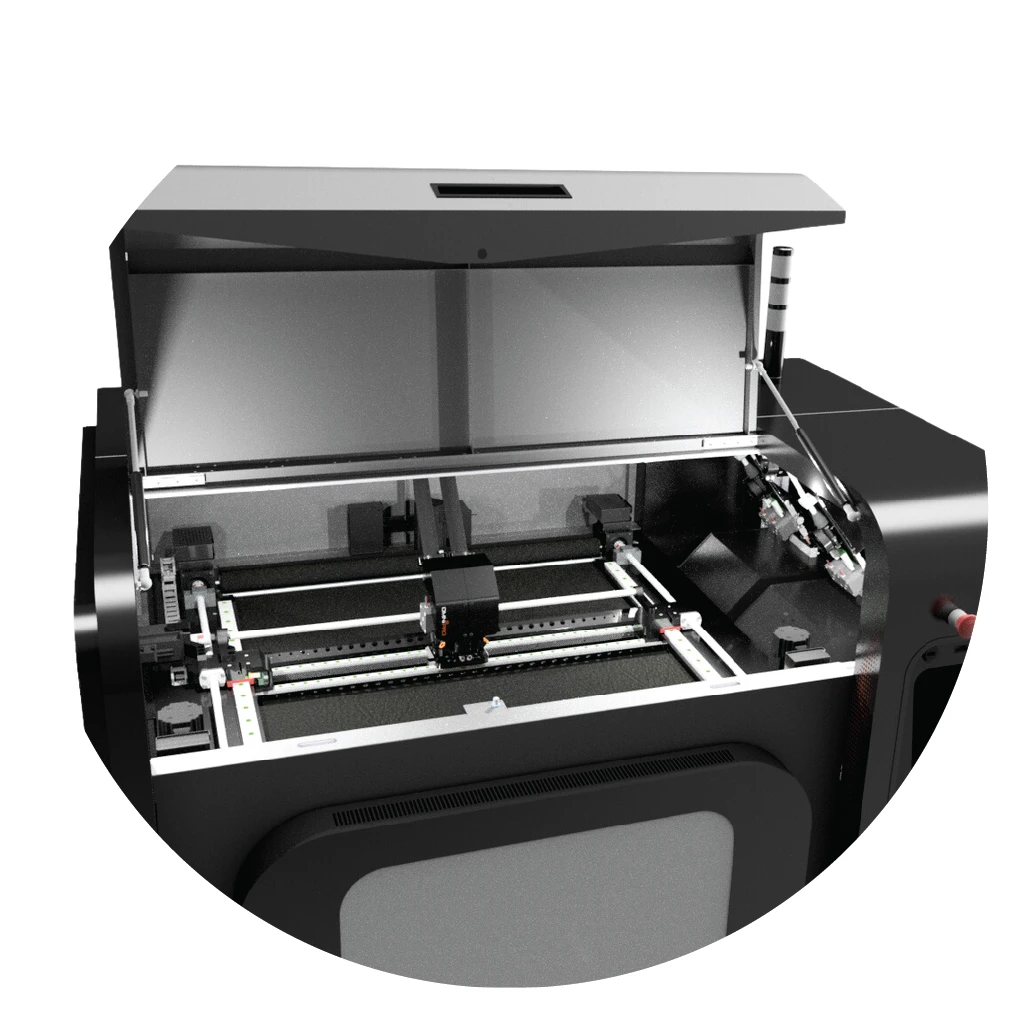

140°C Heated chamber

Remote camera supervision

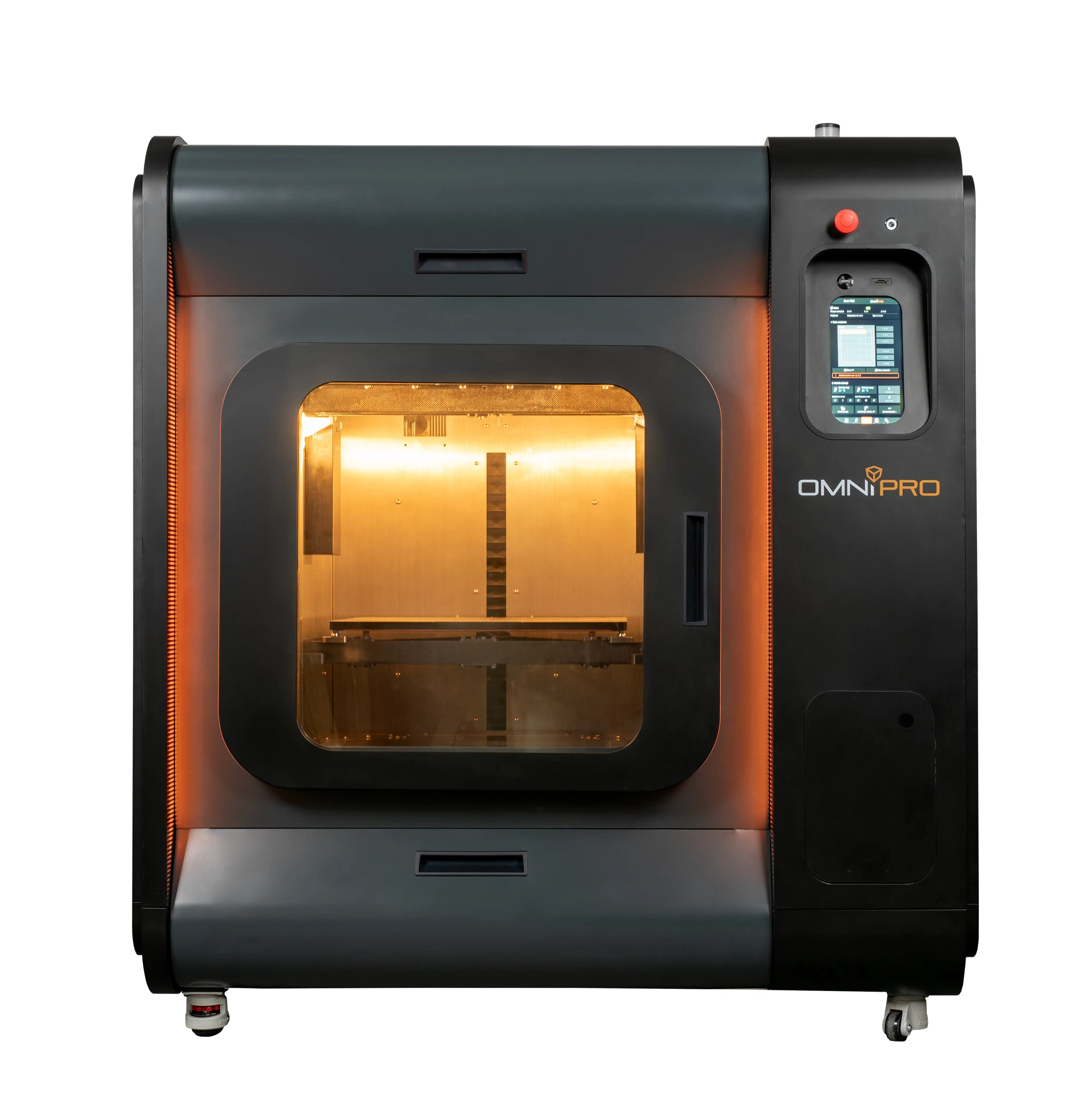

Build Volume 500 x 500 x500

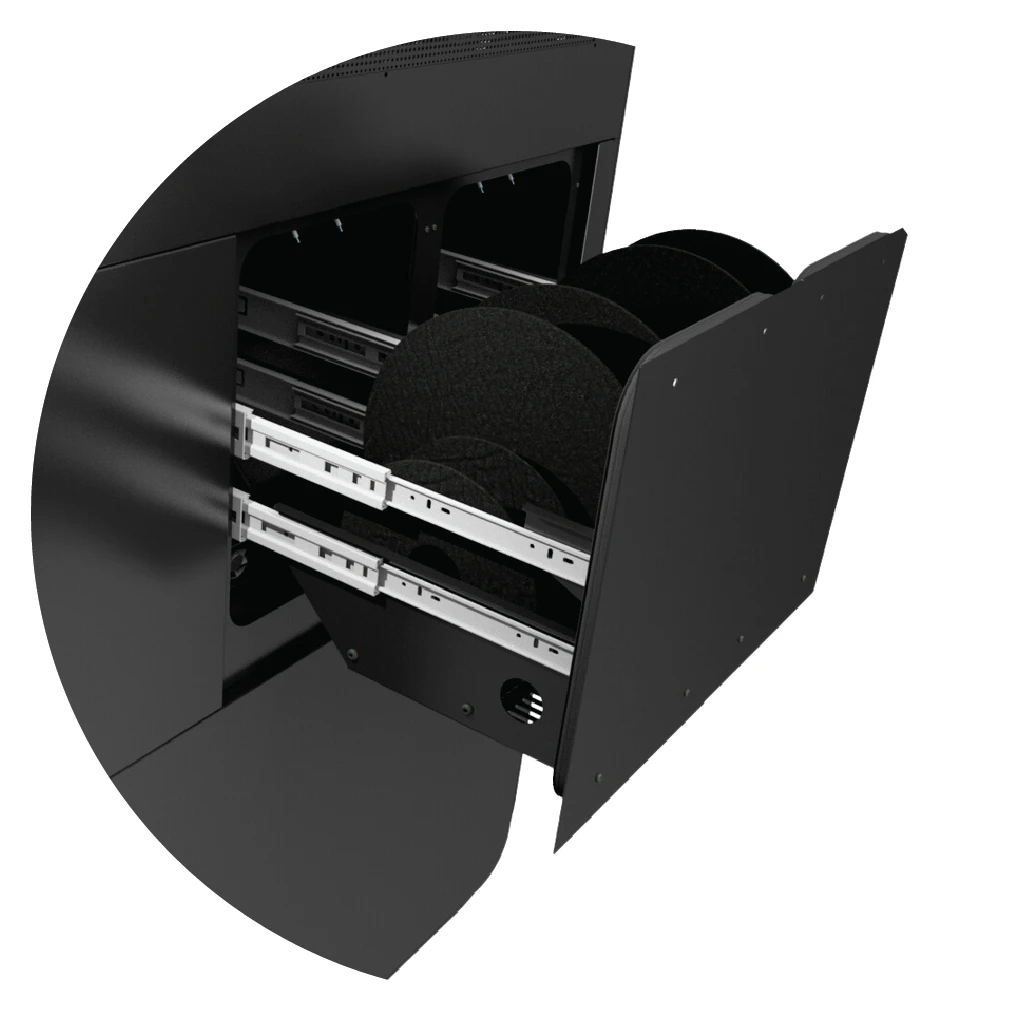

Built-in filament dryer for 4 spools up to 120°C

The Omni PRO offers unique benefits to industrial manufactureres

Large advanced engineering parts in PPS, GF-PPS, and PEKK.

The Omni PRO is optimized for reliably 3D printing big components, empowering you to create high-performance components for demanding applications.

Part performance with proven material compatibility

The Omni PRO’s precisely controlled environment ensures consistent and high-quality results when printing PPS, GF-PPS, and PEKK, maximizing the performance characteristics of these advanced materials.

Efficient integration into production environments.

The Omni PRO simplifies the printing process for PPS, GF-PPS, and PEKK, reducing development time and accelerating time to market.

Robust, low-maintenance platform for production efficiency.

Built for continuous operation, the Omni PRO minimizes downtime and maintenance costs, ensuring consistent and reliable production of high-performance parts.

COMPARISON TABLE

Have questions? Get in touch with our sales team now!

Materials

At Omni3D, we believe in the power of choice. Our open material systems allow you to explore a vast array of materials, tailored to your specific needs. From engineering-grade thermoplastics to specialty filaments, our printers are designed to handle it all.

Omni PRO compatible materials include:

PPS

Car door handle prototype

GF PPS

Train folding

tables

PEKK

BMP-1 Manhole

key

PEKK

Gauge

PEKK

Window roller

part

Applications

Omni pro Specifications

| Build volume XYZ | 500 x 500 x 500 mm |

| Chamber | Enclosed, Isolated and actively heated |

| Max. chamber temperature | 140°C |

| Max. head temperature | 500°C |

| Max. platform temperature | 180°C |

| Built-in filament dryer for 4 spools | Yes (max. 4 x 3 kg), up to 120°C |

| Automatic change of filaments | Built-in accessory drawer |

| Max. power consumption | 160 x 110 x 150 cm |

| Printer dimensions | 50 kg |

| Brochure | Download |

Industrial 3D printing solutions trusted by