ADDITIVE MANUFACTURING FOR MAINTENANCE, REPAIR, AND OVERHAUL (MRO) INDUSTRY

Rapid & Cost-Effective Replacement Parts & Tooling: Omni3D’s Large-Format Industrial Printers Enable On-Site Production of Durable Components, Significantly Reducing Equipment Downtime and Inventory Costs.

Minimize Downtime with On-Demand MRO Solutions

Omni3D’s industrial 3D printers provide rapid, cost-effective solutions for producing replacement parts, tooling, and fixtures for MRO applications. Reduce inventory costs and eliminate long lead times with our robust, reliable systems, ensuring your operations stay running smoothly.

Partner to leading companies

Samsung is a South Korean multinational conglomerate known for its cutting-edge technology and innovation. It is a global leader in electronics, producing smartphones, TVs, semiconductors, and home appliances, while also investing in AI, 5G, and renewable energy solutions.

FlexLink is a Swedish company specializing in automated production flow solutions. It provides smart conveyor systems and industrial automation for various industries, including food, pharmaceuticals, and automotive, enhancing efficiency and flexibility in manufacturing.

John Cockerill is a Belgian industrial group with a strong legacy in mechanical engineering. It operates in energy, defense, and industry, offering solutions in hydrogen technology, military equipment, and large-scale industrial machinery.

Meyra is a leading German manufacturer of mobility solutions, specializing in high-quality wheelchairs and rehabilitation equipment. With decades of expertise, it focuses on improving accessibility and independence for people with disabilities worldwide.

application cases

Robotic Arm Safety Cover

Low Volume Manufacturing

Check Gauge

JIGS & TOOLING

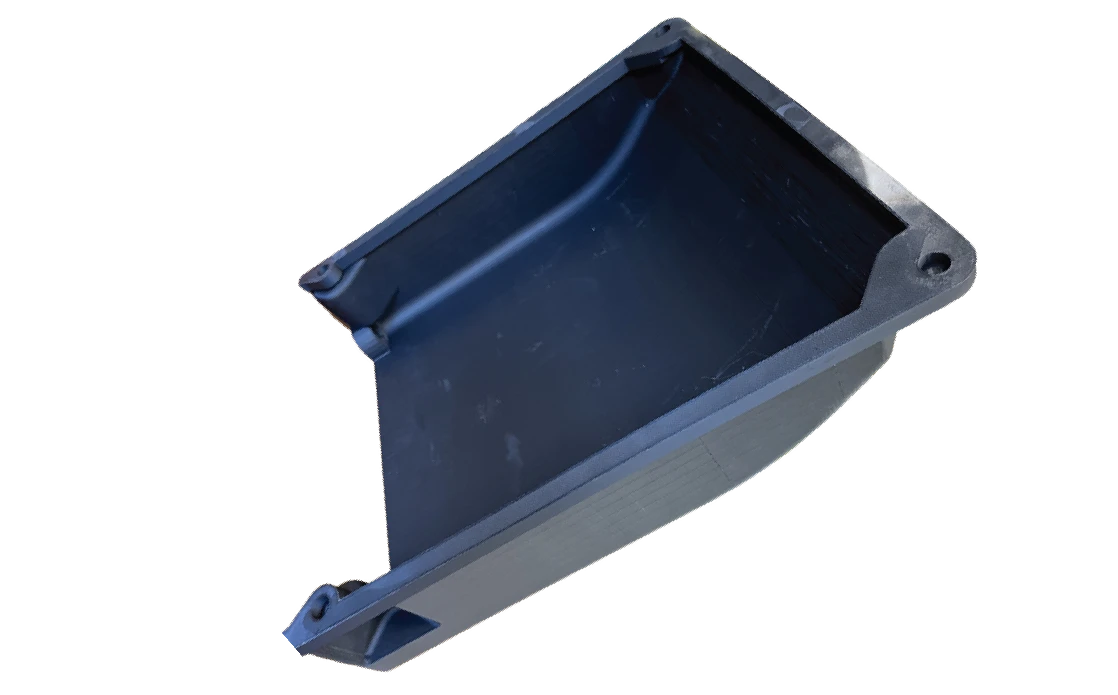

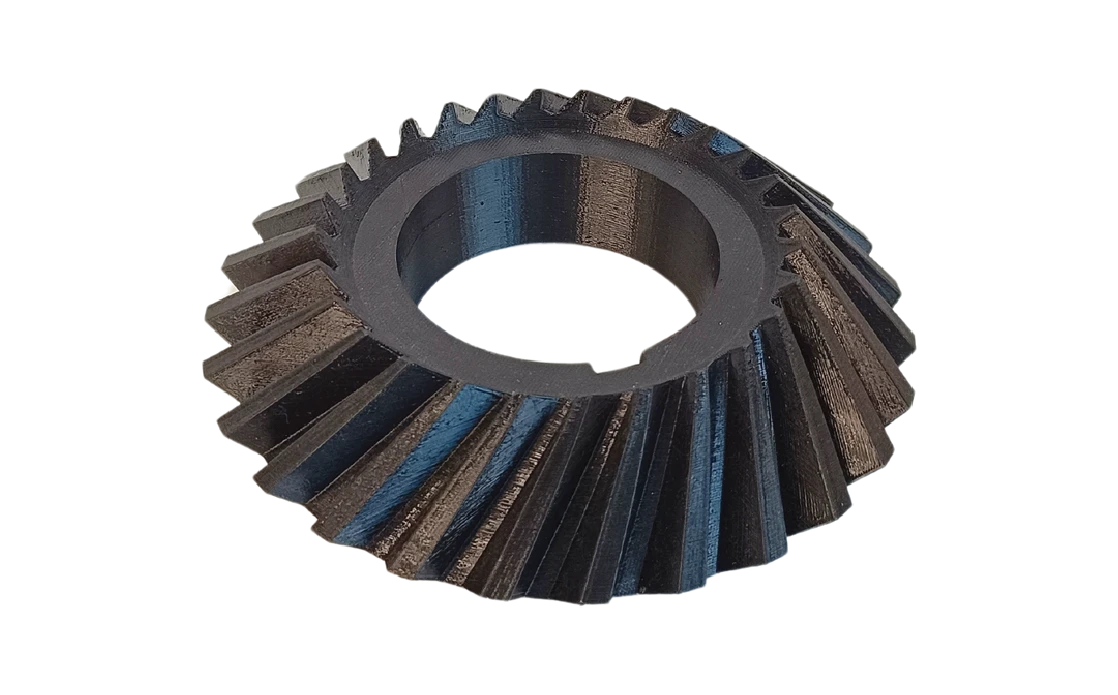

Metal sheet bending knife

Replacement Part

3d printers for maintenance

OmniPRO |

OmniTECH |

OmniLITE |

|

|---|---|---|---|

| Build size | 500 × 500 × 500 mm | 500 × 500 × 570 mm | 460 × 460 × 560 mm |

| MAX. HEAD TEMPERATURE | 500°C | 420°C | 360°C |

| Max Chamber temperature | 220 °C (ACTIVELY HEATED) | 70 °C (ACTIVELY HEATED) | 50 °C (PASSIVELY HEATED) |

| BUILT-IN FILAMENT DRYER | YES | NO | NO |

| Brochure | Download | Download | Download |

Materials

At Omni3D, we believe in the power of choice. Our open material systems allow you to explore a vast array of materials, tailored to your specific needs. From engineering-grade thermoplastics to specialty filaments, our printers are designed to handle it all.

Omni compatible materials include:

ABS ESD

CF-PA12

PC

PEKK

ABS

Industrial 3D printing solutions trusted by