Author: Monika Niedźwiedzińska

Many articles have been written about the use of 3D printing in the fight against the COVID-19 pandemic. Such initiatives as: #MaskForMedic – 10 thousand masks for health care, Diving Mask adapted to hospital respirators thanks to 3D printers or Omni3D project provides a face shields project. Such projects filled with hope and confirmed the potential of 3D printing technology, which became perversely popular in this difficult period. However, for many years scientists, engineers and doctors have been working on the use of this technology in the broadly understood health care.

How can future medicine use 3D printing?

- PERSONALISED printouts (dentures of extremities, blood vessels, teeth, jaws, bone parts, skulls), implants, 3D bioprinting

- DIAGNOSTICS (preoperative, treatment planning)

- FAST REACTION – a modern patient is a physically active person, often practicing extreme sports (more injuries, but also the need for quick rehabilitation).

- LESS COSTS for producing personalized “replacement parts”

- NEW MEDICAL TOOLS, SPARE PARTS, TEACHING AIDS

The popularity of personalized precision medicine is steadily growing. More and more hospitals are buying 3D printers. Long-term partnership agreements are made with printer manufacturers, because it is no longer just about selling a machine, but about introducing customized 3D technology for the daily work of medical services. The possibilities of using 3D printing in medicine are extremely wide.

Analysis of anatomical models in 3D technology

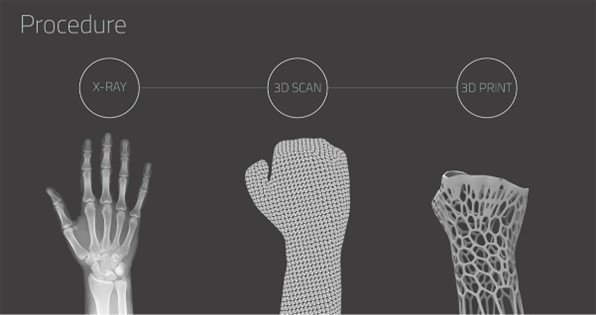

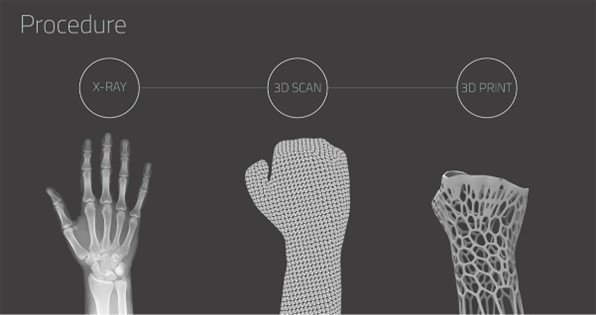

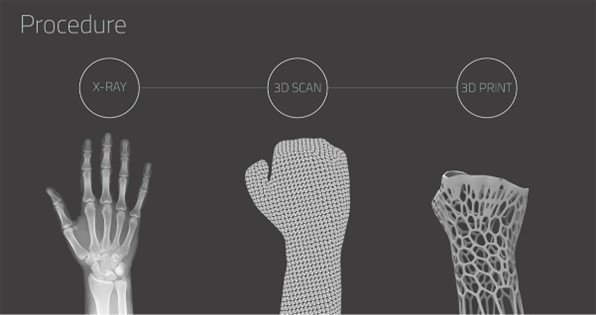

In medicine, a digital model is created on the basis of available imaging data, i.e. CT scans, MRI and ultrasound. Currently, 3D scanners have also been added to the diagnostic equipment, which will certainly soon be used in all hospitals. 3D scanners allow to obtain a realistic and accurate representation of external surfaces and provide fast, contactless and safe measurements. Thanks to it, the patient’s medical image can be visualized and then transformed into a suitable 3D file, which will be sent to a 3D printer.

When doctors realized the power of visualization and planning operations with 3D models, professional 3D printing laboratories were created in many clinics and hospitals. Employees create anatomical models printed in 3D as reference tools for pre-operative planning, intraoperative visualization and size selection.

3D printing – support in planning operations

Virtually planned surgery significantly reduces the time of the actual procedure, but also eliminates the risk of potential mistakes. Surgery planning with printed 3D models is a widely used procedure today. 3D prints make the work easier not only for doctors, who can see the organ before the surgery and without any surgical intervention perform for example a trial cut. After such training during the surgery, there is no possibility to make a mistake or to improvise from doctors. The advantages of 3D printing are also appreciated by patients and students, for whom the explanation of the operation with the use of a printed, e.g. kidney, is much clearer and more comprehensible than the image from CT or ultrasound.

Application of 3D printing in stomatology

3D printing also affects the dental industry. Over the last few years, the additive manufacturing has offered new possibilities in the creation of braces, dentures and dental crowns. Thanks to 3D technology, the dentist can make implants very quickly, avoiding the long process of forming, trying and difficult fitting. It saves valuable time and at the same time reduces pain for patients.

3D printing in physiotherapy and rehabilitation

Professionals around the world use 3D printing to design patient-specific insoles and orthoses, as well as other tools to speed up physiotherapy. The physiotherapists confirm that 3D printed insoles and orthoses are delivered faster and better fit. This ensures better therapeutic results and patients feel less discomfort during use. Isn’t that what this is all about?

The medical revolution and 3D printing

The medical industry has always needed affordable, reliable tools, but the challenge was that there are no two identical patients, cases and diseases. 3D printing technology solves this problem, making it increasingly present in this industry. Every day we hear about a new discovery, another application or a successful operation involving 3D printing. All this drives development and makes the cost of 3D printers and materials systematically decrease, their spectrum and properties are improved. Further barriers to the production of organs for transplantology are being overcome. We witness and benefit from this medical revolution.

Omni3D participates in a medical project using 3D printing – details in 2021!

Do you want to know more about the use of 3D printing in medicine?

Contact us and find out examples of 3D printing applications in medicine

Contact:

LinkedIn: Monika Niedźwiedzińska

m. +48 881 757 632

e-mail: mn@omni3d.com