How to calculate maximum overhang angle

The use of supports is an inseparable part of working in 3D printing. In places where the overhang angle of the printing walls exceeds the boundary angle, the program used to prepare the printout will insert additional structures that will serve as support for the printed element. Depending on whether your printer is equipped with one or two printheads, the supports are made of the same material as the model or from a different filament, such as PVA or HIPS.

What is overhang?

Overhang is the angle of inclination of the print wall from the vertical axis. If the overhang exceeds the maximum angle defined in the settings, a support is generated under the printed wall

What is a support?

The support is an additional lightweigth structure that supports the model where the next layer would be printed 'in the air’. After printing, the support is removed by breaking or dissolving (it depends on the filament used).

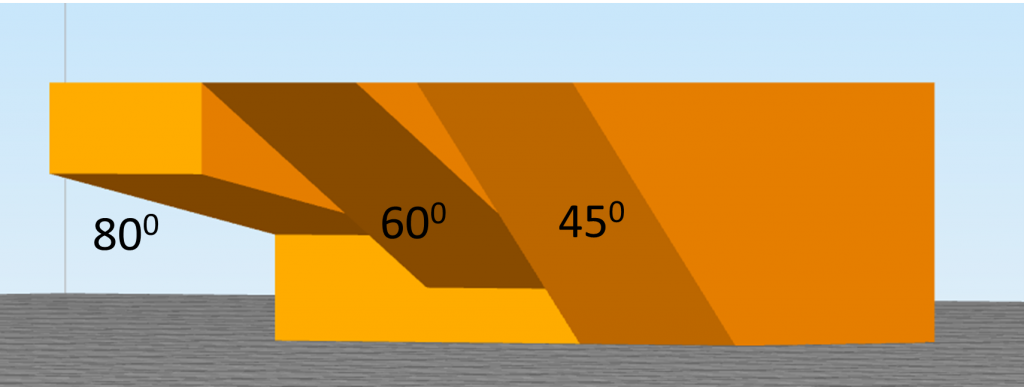

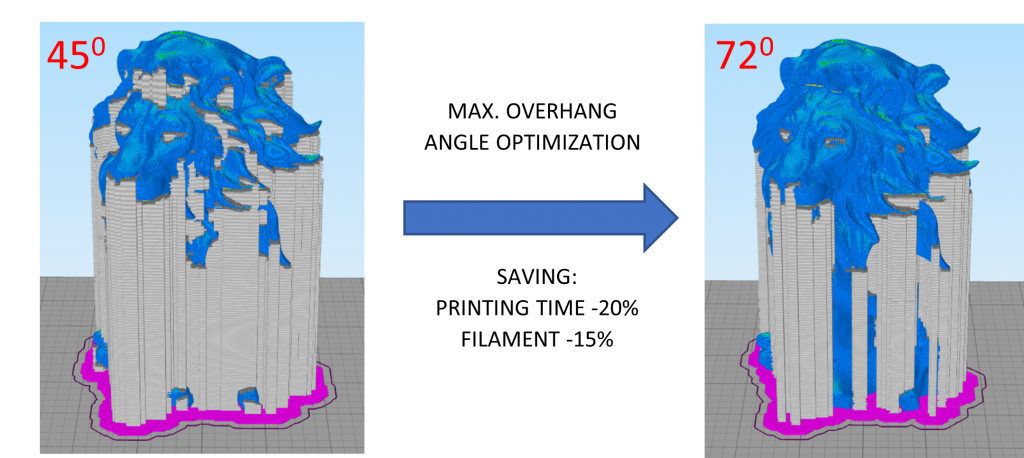

Printing a support is always a cost. Printing time is longer and the amount of material used is higher. Therefore, it is important to adjust the max overhang angle so that the supports are used only where they are most necessary. Thanks to this, the printout will last shorter and the consumption of the filament will decrease.

Most often a relatively low value of about 45 is used, which guarantees that all print elements that require support will be printed correctly. However, the lower the MOA value, the more supports will be printed. Therefore, it is important to set the highest possible value.

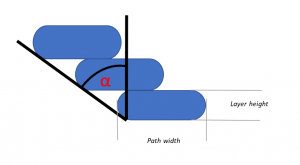

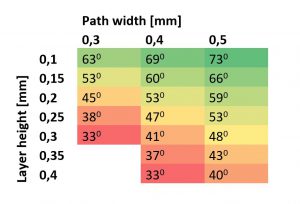

Importantly, the MOA value is not constant and varies depending on the printing parameters used. The basic settings that determine the MOA are the width of the printed filament path and the layer height. The higher the layer height, the lower the MOA we have to apply. On the other hand, increasing the path width will increase the MOA

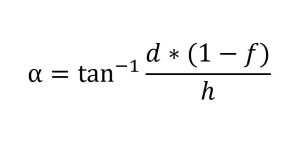

α – maximum overhang angle,

d – width of the printed path,

f – percentage overlap of the printout outlines (the sugested default is 33%),

h – layer height.

Below you can find the calculated max overhang angle for common settings:

By using the MOA calculation method you will not have to experiment with the settings, and by changing the layer height, for example, you will always choose the optimal number of supports for your print.

Want to know more about the possibilities of 3D printing

Interested in the possibility of 3D printing on demand?

Contact us and find out more about the possibilities of industrial 3D printers

![]()

Kontakt:

LinkedIn: Krzysztof Kardach

e-mail: printroom@omni3d.com