by admin | Feb 12, 2024 | Case Study, Maintenance

John Cockerill Services is a leading provider of industrial equipment maintenance solutions for a large number of industries such as chemicals, steelmaking, petro-chemicals, railways, ports, inland waterways, cement, mines and quarries, renewable and nuclear energy. It designs and supplies unique pieces of new industrial equipment, components and sub-assemblies (shunting locomotives, gearboxes, reducers, butterfly valves and diesel engines) along with spare parts for legacy equipment repair.

by admin | Feb 10, 2024 | Case Study, Maintenance

The possibilities offered by 3D printing technology have been used for a long time in the automotive industry and at every stage of production – from prototyping to the production of spare parts and final elements. The available materials allow us to print not...

by admin | Feb 10, 2024 | Case Study, Knowledge, Maintenance

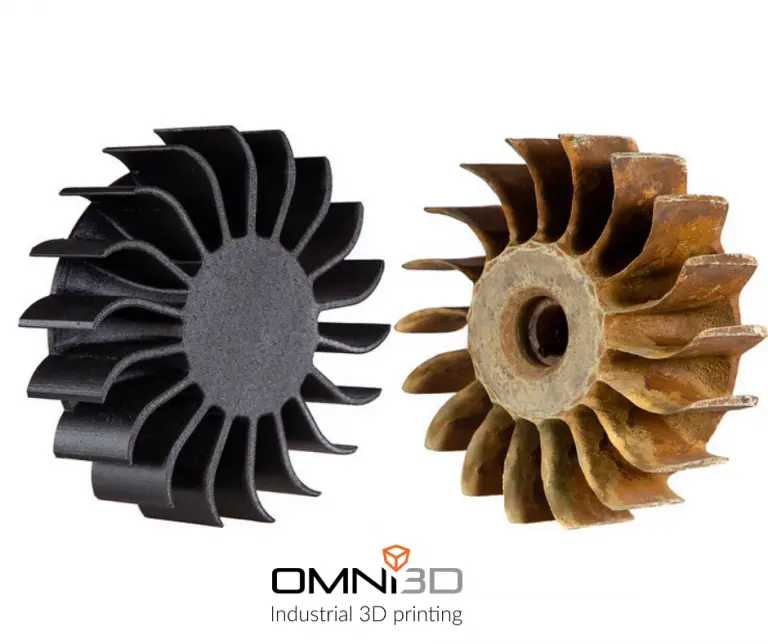

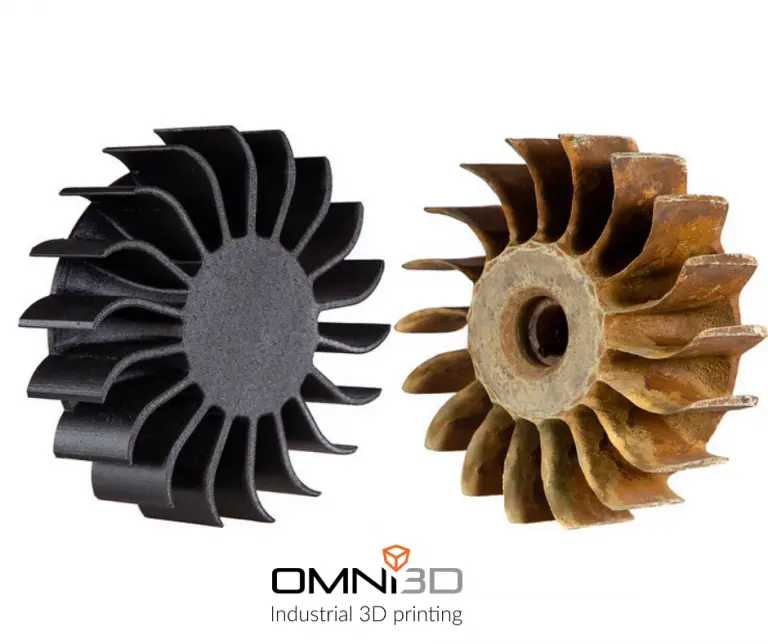

Luk-Plast, a plastics recycling company, commissioned us to print an impeller for a vacuum pump in a process line where waste plastic film is recycled into pellets. Our job was to design the impeller to effectively replace the existing brass component, both on a...

by Gioia G | Mar 29, 2023 | Case Study, Manufacturing

Advanced Robotic Engineering is an innovative robotics engineering company. The Wroclaw-based company designs, manufactures and develops mobile industrial robots that improve work efficiency and safety. ARE has ordered Omni3D to 3D print a remote control housing. The...

by Gioia G | Sep 8, 2022 | Automotive, Case Study, Manufacturing

An automotive manufacturing company approached Omni3D with a request to print a custom part of a police car body component. The main goal was to finalize the project quickly while staying on budget. Instead of having to produce an expensive injection mold, we used the...

by admin | May 13, 2021 | Automotive, Case Study

PRz Racing Team asked us to print another part for the PMT-03 car. This is the third part printed by Omni3D after the intake manifold and gear mount.