Resources

Insights, trends, and actionable strategies for aerospace, automotive, industrial maintenance, and defense industries using cutting-edge large-format 3D printers.

3D Printed Rotor for a Pulse-Free Gas Meter CGR-05

Case study: Common S.A. (Energy sector)

High dimensional accuracy for end-use parts

3D printing is often associated with prototyping. This project highlights something different: 3D ...

3D Printed Scale Model for a Container Transformer Station (FUTURA)

Case study: ELGÓR + HANSEN S.A. (Energy sector)

3D printed scale model prototyping can turn large, complex products into fast, portable, and low-cost presentation tools, especially when ...

3D Printed Car Body Prototype in PC-ABS

Case study: SUPERQUAD SLOVAKIA s.r.o. (Automotive)

A common bottleneck in automotive prototyping is dependency on external suppliers, especially when parts must be produced fast, iterated, ...

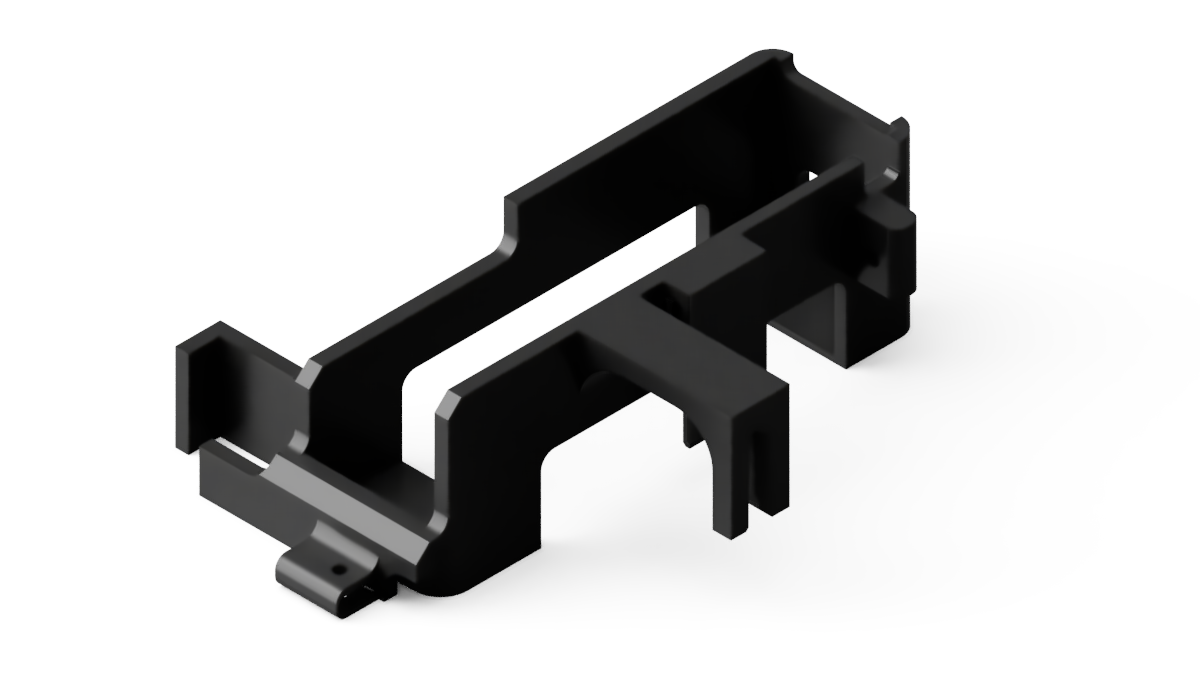

Increase Strength of 3D Printed Parts by Splitting the Model and Optimizing Orientation

Case study: Diehl Controls

Increase strength of 3D printed parts is often limited by anisotropy in FFF printing—especially along layer lines. This case study shows how splitting the model and ...

Breaking Vendor Lock-In: How Omni TECH Reduces Machine Downtime Costs

Learn how the Omni TECH industrial 3D printer helps maintenance engineers eliminate vendor lock-in, reduce spare parts lead times from 8 weeks to 3 days, and achieve ROI in the first ...

Why Omni3D Recommends ASNARE for High-Temperature 3D Printing

First-layer adhesion is the single most critical factor preventing polymer warpage and build failure when processing High-Performance Polymers (HPPs) in industrial systems. In the context of a ...

Navigating Rail Filaments: Why Printout Certification Matters for Railway Additive Manufacturing

The railway sector is increasingly embracing additive manufacturing for its potential to revolutionize design, streamline production, and enhance maintenance. As the industry advances, so does ...

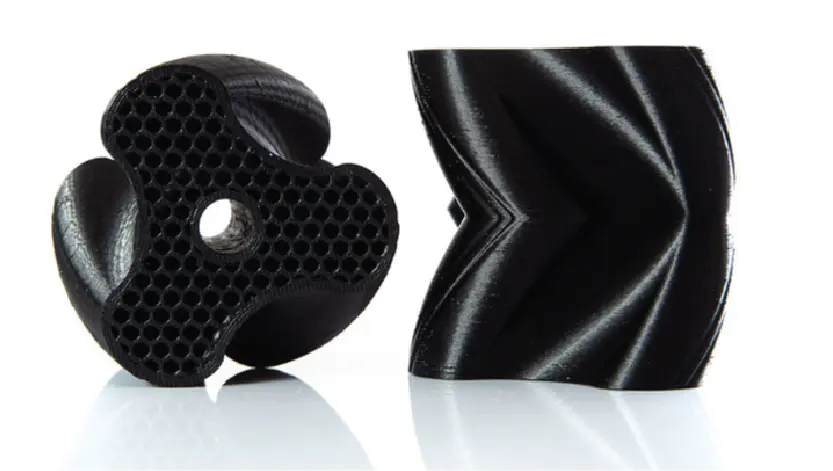

A Practical Guide for 3D Printing Functional Industrial Parts

Achieving complex geometries and intricate features often necessitates the use of support structures. These are temporary scaffolds that help the printer hold up filament in places where there’s ...

Industrial Large Heated Chamber Printers needs OSD-20 Soluble Support Material

Omni3D large-format heated chamber industrial 3D printers is designed to meet the demands of high-performance applications. Omni3D printers are engineered to deliver unmatched precision, ...

What Are Industrial 3D Printers Used For? Enhancing Modern Manufacturing

Industrial material extrusion 3D printing, or additive manufacturing (AM), has firmly established itself as a reliable and indispensable process within the global manufacturing landscape. Far ...

No results found.

Industrial 3D printing solutions trusted by