Resources

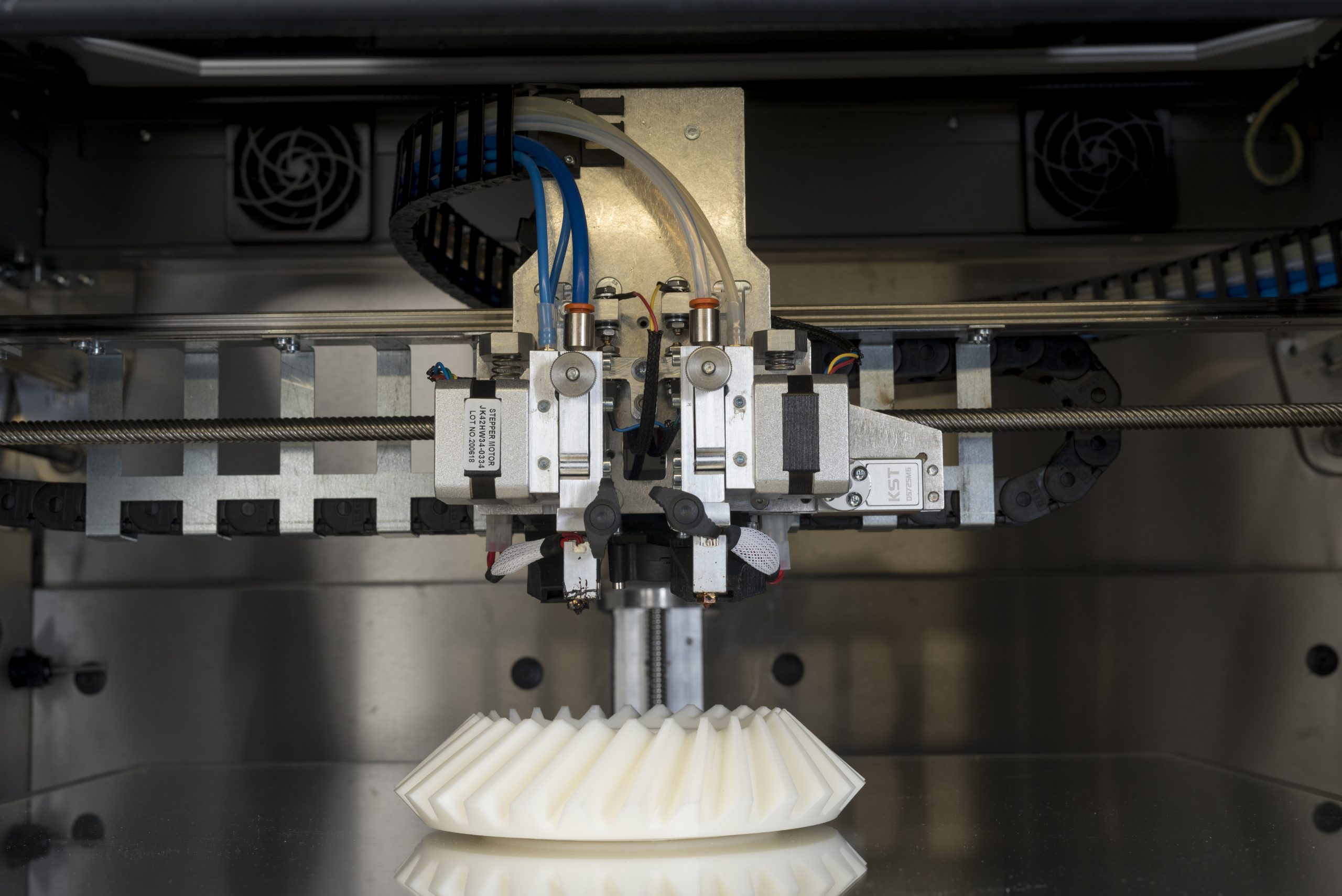

Insights, trends, and actionable strategies for aerospace, automotive, industrial maintenance, and defense industries using cutting-edge large-format 3D printers.

The Role of Adhesives in FDM 3D Printing: Your Key to Perfect Prints

In material extrusion 3D printing, ensuring proper first-layer adhesion to the build plate is paramount for success, especially in large-format prints. A well-adhered print guarantees precise ...

Reviving Obsolete Machinery: On-Demand 3D Printing for Agricultural Spare Parts

In the demanding world of agriculture, downtime is costly. When critical machinery parts become obsolete or unavailable, it can halt operations and disrupt productivity. That's precisely the ...

Replacing Metals With 3D-Printed: High-Performance Polymers

Are you struggling to replace large metal parts in your manufacturing processes? Discover how Omni3D's 10+ years expertise with companies like yours and open-source large-format industrial 3D ...

Optimizing BOSCH Production efficiency with 3D Printing

Faced with the challenge of safely transporting sensitive electronic components, BOSCH sought a reliable, fast and efficient solution. By partnering with Omni3D, they were able to develop a ...

3D Printing for Industrial Robotics: Custom Frame Component for Robotic Arms

Flexlink, a leader in manufacturing automation, needed a solution to create custom protective covers for robotic arms to meet safety standards in collaborative workspaces. Omni3D provided an ...

Aerodynamic studies on combat aircraft FA-50

In the age of technological advancement, 3D printing is becoming a crucial tool supporting the development of modern scientific and industrial research. A prime example of this is the ...

The Use of 3D Printing in AIRFUKA’s Touchless Car Dryers

AIRFUKA is a leader in innovative solutions in the field of car wash touchless air blowers with airflow power exceeding 500 km/h. Their products are characterized by unparalleled performance and ...

3D Printing on Textiles

3D printing technology is gaining popularity across various industries, offering new opportunities for design and production. One of the latest and most innovative applications of this ...

3D printing replacing steel

Eba sp. z o.o., based in Krosno, specializes in metal processing and production of all kinds of metal parts. It is constantly developing its production capabilities, the specialists use 3D ...

Chamber Temperature’s Impact on Strength in material extrusion

Achieving optimal part quality in additive manufacturing material extrusion often hinges on factors beyond mere geometry and material selection. One such critical aspect is the controlled thermal environment provided by heated chambers, particularly when working with advanced materials like super polymers.

No results found.

Industrial 3D printing solutions trusted by