Resources

Insights, trends, and actionable strategies for aerospace, automotive, industrial maintenance, and defense industries using cutting-edge large-format 3D printers.

Large-Format, Heated Chambers: The Cornerstone of Defense-Grade 3D Printing

Reliability and performance are paramount in defense and 3D printing has emerged as a transformative technology. The successful implementation of this technology hinges on several critical factors, with chamber size and temperature control standing out as particularly crucial to blend 3D printing into established manufacturing processes.

Material Matters: Choosing the Right Filament for Defense Applications

When it comes to 3D printing for defense applications, material selection is paramount. The ability to choose the right filament is crucial for producing parts that meet the stringent requirements of military operations and lasts.

Maximizing 3D Printing Success: The Key to Drying Filament for High-Temperature Polymers

Welcome to our blog! In this post, we will delve into a crucial aspect of achieving optimal results in material extrusion 3D printing: the importance of drying filament, especially when working with engineering high-temperature polymers. We will explore the benefits of filament drying and share valuable insights on how to reduce costs along the way.

Soaring to New Heights: Material Extrusion takes Flight in Aerospace Applications

Building upon our commitment to safety-first innovation in regulated markets, Omni3D's industrial extrusion 3D printing technology is taking flight in the demanding world of aerospace. This blog entry, a continuation of our exploration of 3D printing within highly regulated industries, dives deeper into the specific considerations and exciting possibilities for large-format material extrusion within the aerospace sector.

Mastering the Cool-Down: Thermal Management in Large-Format Industrial 3D Printing

In the realm of large-format industrial 3D printing, achieving optimal part quality demands meticulous attention to every stage of the process. While the excitement often lies in the creation of complex geometries, in industrial applications the often-overlooked cooling phase is paramount for ensuring dimensional accuracy, mechanical properties, and overall part performance.

Pioneering Industrial Extrusion 3D Printing for Regulated Markets: Safety First with Openness for Innovation

In the fast-paced world of transportation, safety regulations are the cornerstone of every innovation. At Omni3D, we understand this responsibility deeply. That's why our industrial extrusion 3D printing technology prioritizes not just cutting-edge capabilities, but also strict adherence to critical safety standards.

Omni3D Earns NCAGE Code (9BT1H): Boosting Industrial 3D Printing for the Defense Sector

Major news for the defense sector and industrial additive manufacturing! Omni3D has been officially granted the prestigious NCAGE code (9BT1H). This signifies our commitment to delivering ...

From Brainstorm to Boardroom: How ORSA Streamlined Office Chair Design with Omni3D’s Large-Format Printing Powerhouse

In the ever-evolving world of product design, efficiency and innovation are the cornerstones of success. This is precisely the challenge ORSA, a leading engineering services company with a keen ...

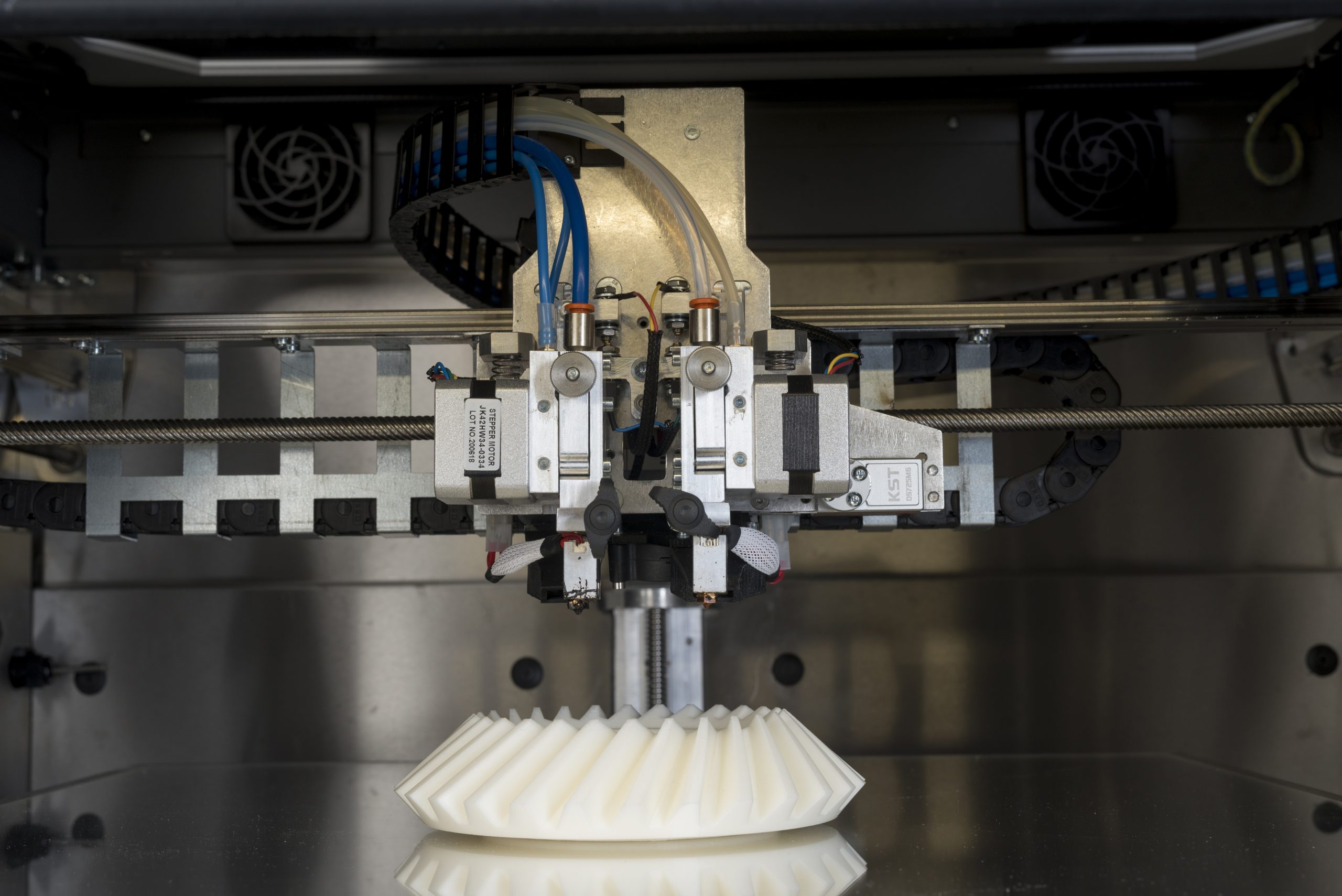

Large-format 3D printed parts accelerates repairs of legacy industrial equipment

John Cockerill Services is a leading provider of industrial equipment maintenance solutions for a large number of industries such as chemicals, steelmaking, petro-chemicals, railways, ports, inland waterways, cement, mines and quarries, renewable and nuclear energy. It designs and supplies unique pieces of new industrial equipment, components and sub-assemblies (shunting locomotives, gearboxes, reducers, butterfly valves and diesel engines) along with spare parts for legacy equipment repair.

Automotive: Durable spare parts printed on an industrial 3D printer

The possibilities offered by 3D printing technology have been used for a long time in the automotive industry and at every stage of production - from prototyping to the production of ...

No results found.

Industrial 3D printing solutions trusted by

Latest blog posts

What Are Industrial 3D Printers Used For? Enhancing Modern Manufacturing

Industrial...

How to Choose the Optimal 3D Printing Technology for Your Industrial Application: A Comprehensive Guide

Industrial...

What Are Industrial 3D Printers Used For? Beyond Prototyping to Production Realities

For...