Resources

Insights, trends, and actionable strategies for aerospace, automotive, industrial maintenance, and defense industries using cutting-edge large-format 3D printers.

Large-Format, Heated Chambers: The Cornerstone of Defense-Grade 3D Printing

Reliability and performance are paramount in defense and 3D printing has emerged as a transformative technology. The successful implementation of this technology hinges on several critical ...

Soaring to New Heights: Material Extrusion takes Flight in Aerospace Applications

Building upon our commitment to safety-first innovation in regulated markets, Omni3D's industrial extrusion 3D printing technology is taking flight in the demanding world of aerospace. This blog ...

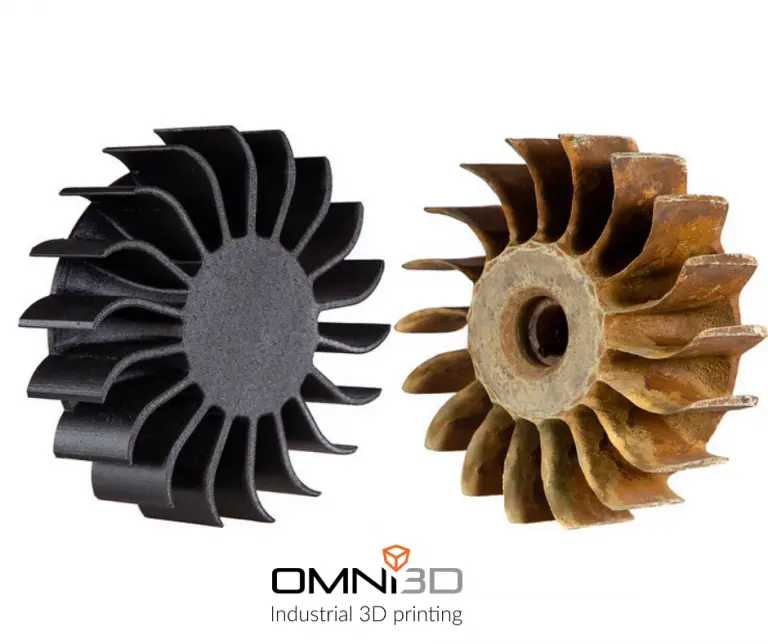

Refurbishment of a vacuum pump using 3D printing technology

Luk-Plast, a plastics recycling company, commissioned us to print an impeller for a vacuum pump in a process line where waste plastic film is recycled into pellets.

Our job was to design the ...

Remote control housing – 3D printing in the production of final components

Advanced Robotic Engineering is an innovative robotics engineering company. The Wroclaw-based company designs, manufactures and develops mobile industrial robots that improve work efficiency and ...

Cheaper and faster low-volume production

An automotive manufacturing company approached Omni3D with a request to print a custom part of a police car body component.

The main goal was to finalize the project quickly while staying on ...

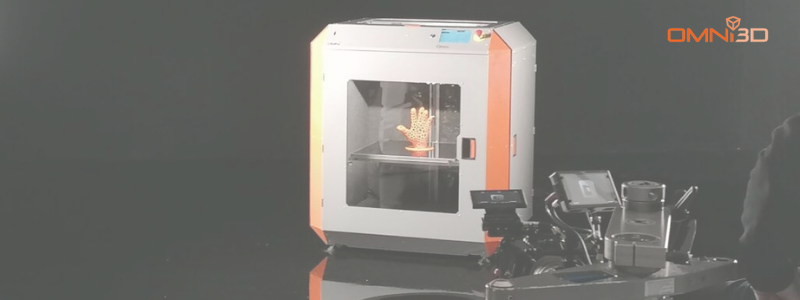

Industrial 3D printing – an unequal battle with desktop printers

In the FDM / FFF technology there is a belief that anyone who can print anything more than PLA, can be treated as a solution for the engineer and industry. What is professional, industrial 3D printing? Where is the line that mark a border between the printers for amateurs, semi-professional and the industry printers for engineers and production? Why, despite many years of existence of 3D printing, the knowledge related to it, is not common? I will try to define the line between, explain the aspects, both technological and usable that is associated with professional 3D printing. That needs to be done, to know what it is, what it gives and makes it different from desktop and semi-professional devices.

BioElectroCathode project – biofuels thanks to 3D printer

BioElectroCathode is an innovative project that aims to apply 3D printing technology to the production of electrochemical bioreactors. Together with Scientists – Omni3D’ team is involved in developing the way to produce cathodes necessary for the bioelectrosynthesis process. The solution is to find a way to convert CO2 from exhaust and the air into biogas that can be used as a fuel. How 3D printing technology from Omni3D can help in production of “the fuels of the future”?

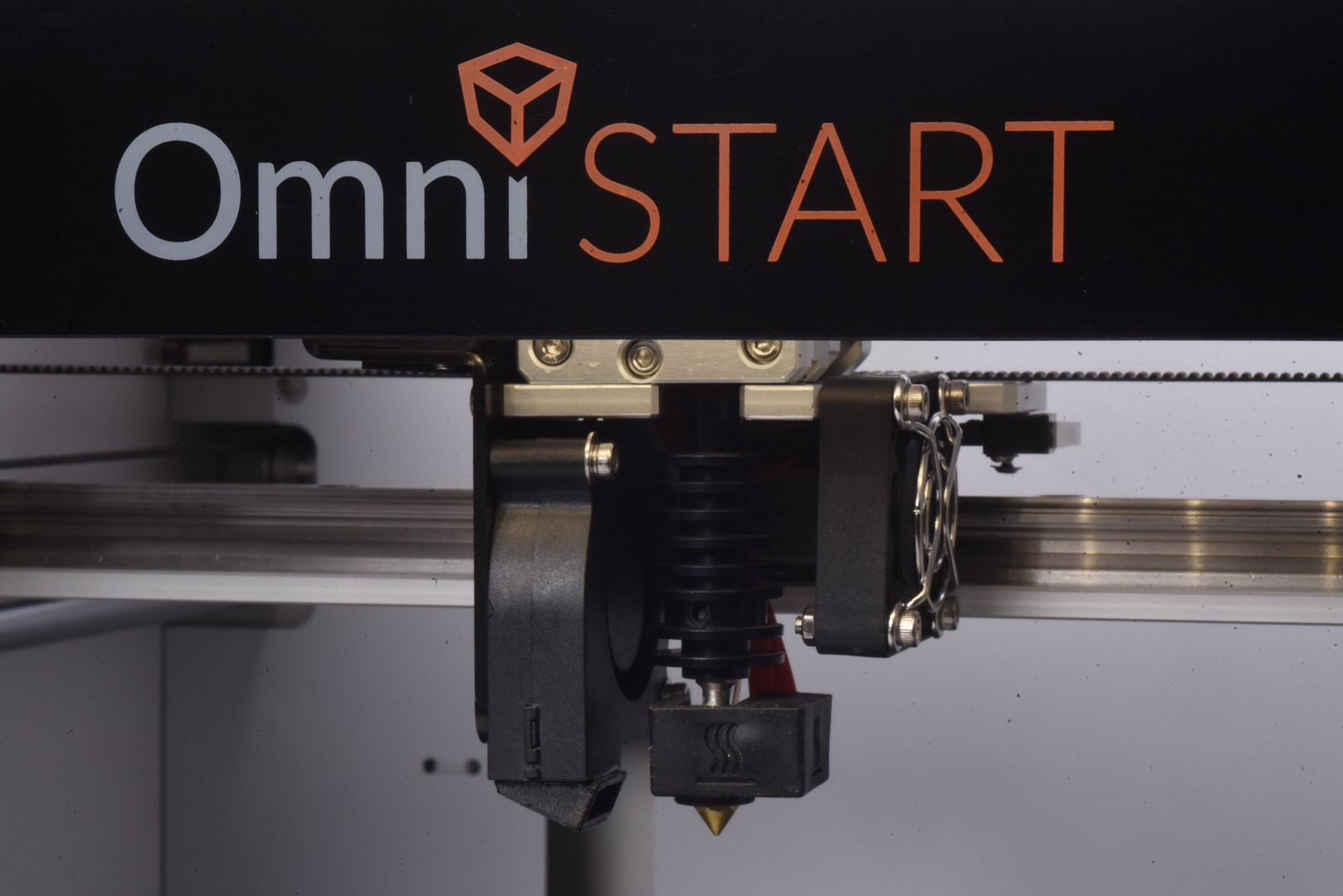

START with 3D printing

It has only been two months since the premiere of the OmniSTART, Omni200 and Omni200 (CF) printers in our online store and we can safely say that these products enjoy a lot of interest. They are used not only in industry, but also in education.

We gain especially valuable experience thanks to lessons conducted for high school students.

Omni3D has received the ISO 9001: 2015 certificate. What changes await the company and customers?

For Omni3D, quality has always been a priority. As a start-up, we have taken many steps to achieve this goal. It has now been formally sealed. On May 4, under number 487345, the ISO 9001: 2015 certificate was issued for Omni3D. The successful completion of the certification audit confirms the compliance of our services and products as a manufacturer of 3D printers with the international standard specifying the requirements for quality management.

3D printing in the production of the final parts of the racing car part 3

PRz Racing Team asked us to print another part for the PMT-03 car. This is the third part printed by Omni3D after the intake manifold and gear mount.

No results found.

Industrial 3D printing solutions trusted by

Latest blog posts

3D Printing Impossible-to-Machine Large 3D Parts for Hexapods

More...

On-Demand Parts for Legacy Armor: Maintaining BMP-1 Vehicles with Omni3D’s Large-Format Printing

Maintainin...

3D Printed Fairings for Suborbital Rocket Boosters: Lighter, Faster, Mission-Ready

In the...