Resources

Insights, trends, and actionable strategies for aerospace, automotive, industrial maintenance, and defense industries using cutting-edge large-format 3D printers.

3D Printing Service – 3D printing on demand

The market for 3D printing services is growing rapidly. It responds to the needs of the changing world and the development of technology. Investment in a professional 3D printing machine is profitable only for high volume 3D printers. 3D custom printing services is an alternative to buying an industrial 3D printer.

3D printing in education

3D printing technology is becoming increasingly popular in school education. 3D printing helps to understand the secrets of three-dimensional space, stimulating children's imagination and perception of reality. This, of course, results in better school achievement. In this article you will learn the benefits of using 3D printing in education!

FDM / FFF technology is a chance for our planet and us- we just need a broader view

For a lot of us, the argument contained in the topic may be controversial - after all, how can something that produces "plastic" be eco friendly and be an element that can save the world? Well, let’s face with this! I will try to prove it in this publication.

3D printing in furniture manufacturing

INEX System, a furniture manufacturing company, asked Omni3D to print 15,000 elements used

in the production of shop furniture. 3D printing turned out to be the cheapest and fastest method of producing parts - compared to traditional production, our client saved time (production ended 21 days earlier) and production costs were reduced by 79%!

3D printing in the production of the final parts of the racing car part 2

The PRz Racing Team decided to use elements printed on a 3D printer when building their car. The task of Omni3D was to print an element that would be adapted to the requirements of racing cars. The gear mount is a geometrically complex printout for the student formula car.

3D printing in the production of the final parts of the racing car

The PRz Racing Team decided to use elements printed on a 3D printer for their project. The task of Omni3D was to print an element that would be adapted to the requirements of racing cars. The inlet manifold is an element exposed to vibrations, high temperatures of approx. 100°C and chemicals.

Optimization of the production line thanks to the Omni3D printer

3D printing allows you to quickly check the accuracy of the dimensions before ordering an expensive form for the production of the tool. Thanks to the Omni3D printer, the customer could try out the designed tool and apply corrections before ordering the production of the final product.

ABS – universal and durable material

ABS, i.e. acrylonitrile butadiene and styrene, is a material that almost all of us have had a contact with. Car parts, machine elements and tool housings are made of ABS, but it is also used in the Electronics Home Appliances and the toy industry.

Large-size 3D printing

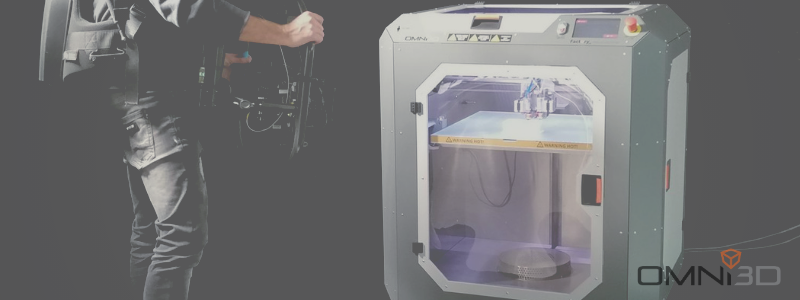

3D printing is not only limited to small parts and models that can be produced with desktop printers. The widespread use of this type of printers causes many people to believe that the dimensions of the printed elements are limited. The alternative turns out to be printing entirely. Some machines offer a very large print volume, which can reach even one cubic meter! This type of professional large-format 3D printer is presented by the industrial Omni3D printers.

Omni200 / Omni200 (CF) – desktop solution from Omni3D

Metal housing, accuracy, speed, build volume enabling the printing of smaller elements - these are only some of the features of desktop 3D printers Omni200 / 200 (CF) from Omni3D. Most importantly, their high quality is also accompanied by an attractive price.

No results found.

Industrial 3D printing solutions trusted by