Resources

Insights, trends, and actionable strategies for aerospace, automotive, industrial maintenance, and defense industries using cutting-edge large-format 3D printers.

Chemical resistant 3D printer filaments

The more we delve into the world of filaments and the possibility of their use in various industries and sectors, the more often we think about chemical "durability". The field of research in this aspect is not yet developed - and some experiments are burdened with a long term of feasibility. What does it mean?

Application of 3D printing in industry

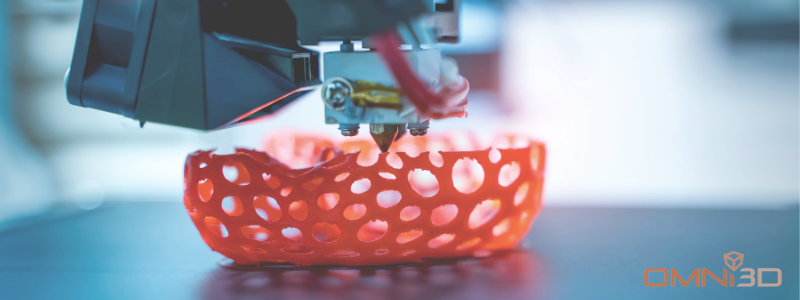

3D Printing is growing more and more in industry. It's a technology that offers newer and better solutions, with the goal of optimising production and improving the quality of manufactured elements. 3D printing not only significantly facilitates and speeds up concept work, but also enables implementation of more effective solutions on production lines.

Can metal components be replaced with 3D printed CF?

3D printing technology gives us the advantage of cost reduction and makes the production time shorter. The 3D printing materials that are available on the market create the possibility to replace even the hardest components on the production lines. So it's no surprise that it's possible to replace metal parts with 3D printing. Today, we will answer the question: why You should choose 3D printing?

Omni3D virtual showroom

The pandemic has forced many companies to transfer sales and communication with customers to the virtual world of the Internet. Year of 2020 forced a lot of enterprenaurs to focus on creativity and marketing activities that would allow for uninterrupted contact with customers at this exceptional time. In response to these needs, Omni3D provides a virtual showroom inviting customers to the world of 3D printing

How to improve FFF 3D print quality?

The quality of a 3D printout is the most important parameter that often determines the use of 3D printing technology to produce a planned component. How to increase the quality of prints in FFF technology? Certainly, we need to pay attention to two key elements: the 3D printer on which we are working and the quality of the filament that we want to use for the project.

When and why is it worth outsourcing 3D printing services?

If You are just getting started with 3D printing technology, considering buying a 3D printer for your business, or just want to see the possibilities of this technology - it is worth to outsourcing the project and 3D printing to companies that specialize in it every day.

What will bring the 2021 in 3D printing?

Experienced by the difficult and unpredictable year of the pandemic, like every industry and segment, FDM technology is coming out of the corner. We have to find ourselves in this strange and new reality by finding new applications for 3D printing. What challenges lie ahead in 2021? The previous years have already directed the development of FDM and although 2020 has slowed it down a bit, the trends are still clear.

How to calculate maximum overhang angle

The use of supports is an inseparable part of working in 3D printing. In places where the overhang angle of the printing walls exceeds the boundary angle, the program used to prepare the printout will insert additional structures that will serve as support for the printed element. Depending on whether your printer is equipped with one or two printheads, the supports are made of the same material as the model or from a different filament, such as PVA or HIPS.

Which filament to choose for spare parts production?

If you have already managed to buy an industrial 3D printer - time for the first printout! Its quality depends on the filament you choose and the choice is not easy at all - the amount of materials available on the market can make you dizzy.

Wake up creativity with 3D Printing

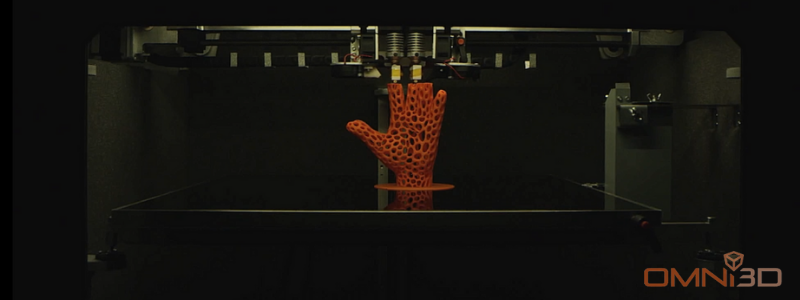

"Release your creativity" - this slogan is present and repeated everywhere, but is it easy to implement? In industry, more attention is paid to not making mistakes, and this restricts the free will and freedom of creation. Safety is a priority in medicine, maintenance, defense and aerospace industries. What if creativity and risk minimization could go hand in hand? What if creativity was the way to reduce the risk?

No results found.

Industrial 3D printing solutions trusted by