Maximizing 3D Printing Success: The Key to Drying Filament for High-Temperature Polymers

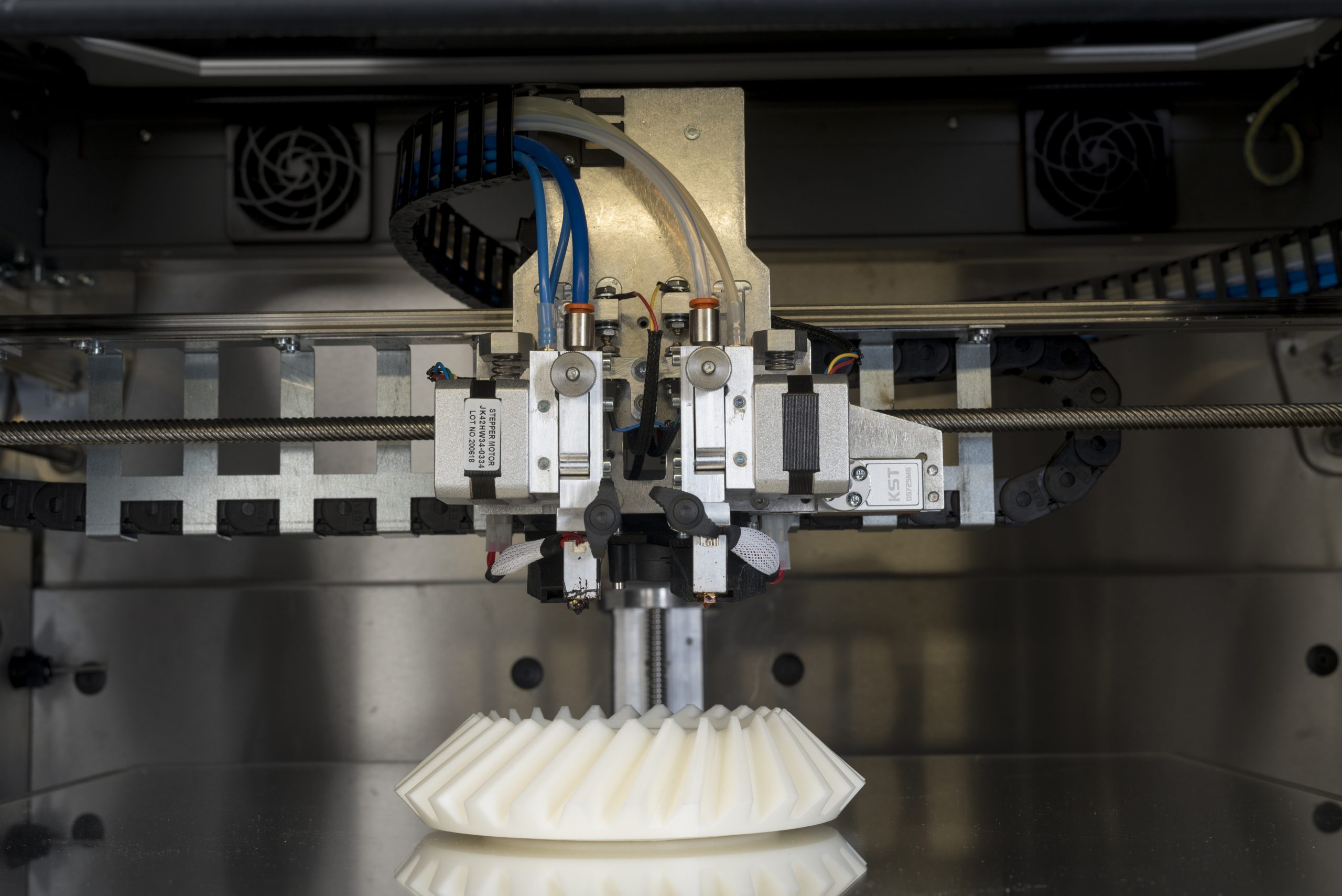

Welcome to our blog! In this post, we will delve into a crucial aspect of achieving optimal results in material extrusion 3D printing: the importance of drying filament, especially when working with engineering high-temperature polymers. We will explore the benefits of filament drying and share valuable insights on how to reduce costs along the way.

Why is filament drying so important, you may wonder?

Well, high-temperature polymers, such as PEEK, ULTEM, and Nylon, possess excellent mechanical and thermal properties. However, they are also hygroscopic, meaning they readily absorb moisture from the air. This moisture content can significantly impact the quality and performance of your 3D prints.

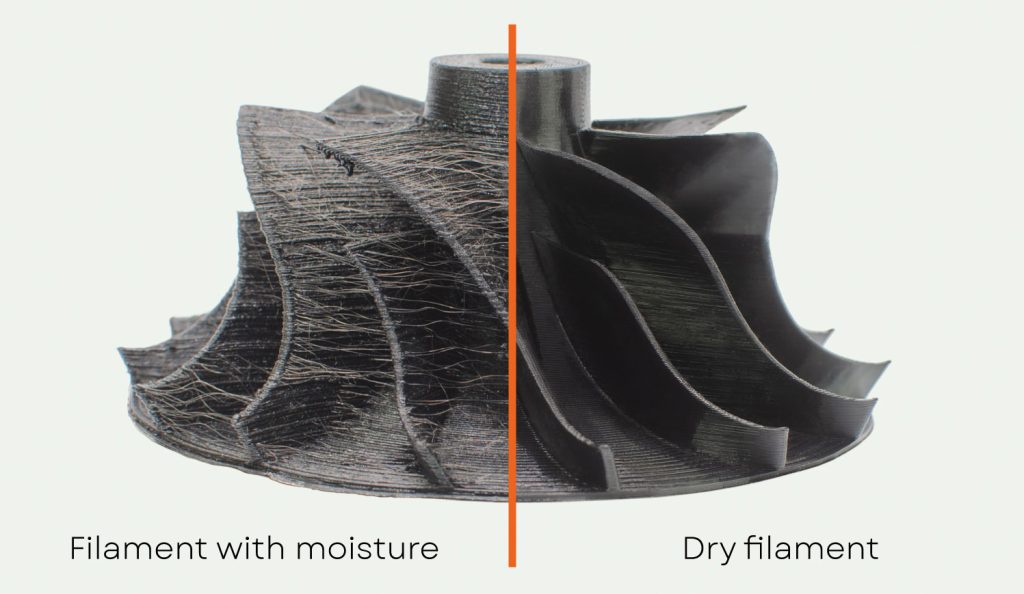

Damp filament can lead to various issues, including decreased print quality, poor layer adhesion, and even structural weaknesses in the final object. Moisture trapped within the filament may cause bubbling, popping, or steam formation during printing, leading to inconsistent extrusion and compromised part integrity.

To overcome these challenges and achieve the best possible results, it is essential to thoroughly dry your filament before printing. By doing so, you eliminate moisture-related defects, improve layer-to-layer fusion, and enhance the overall surface finish of your prints.

Now, you might be wondering about the cost implications. Investing in a filament drying solution may seem like an additional expense, but it can actually save you money in the long run. By drying and preserving your filament properly, you minimize the risk of failed prints and material wastage. This translates into significant cost savings, especially when working with high-value engineering polymers.

To further optimize your filament drying process, here are a few practical tips:

- Utilize a dedicated filament drying chamber: Consider using a specialized drying chamber or a desiccant-based storage system to maintain low moisture levels in your filament.

- Pre-dry your filament: Before printing, follow the manufacturer’s guidelines for temperature and duration to pre-dry your filament effectively.

- Proper storage: Store your filament in airtight containers or vacuum-sealed bags with desiccant packs to prevent moisture absorption between prints.

- Moisture monitoring: Regularly monitor and record the moisture content of your filament using a moisture analyzer to ensure optimal printability.

Remember, drying your filament is not just about achieving superior print quality; it’s also about maximizing the value of your investment in high-temperature polymers. By taking proper care of your materials, you can reduce material waste, minimize print failures, and ultimately improve your bottom line.

We hope this information proves valuable to your 3D printing journey. Dry your filament and unlock the full potential of your high-temperature polymer prints.