Large-Format, Heated Chambers: The Cornerstone of Defense-Grade 3D Printing

Reliability and performance are paramount in defense and 3D printing has emerged as a transformative technology. The successful implementation of this technology hinges on several critical factors, with chamber size and temperature control standing out as particularly crucial to blend 3D printing into established manufacturing processes.

The Imperative of Large Build Volumes

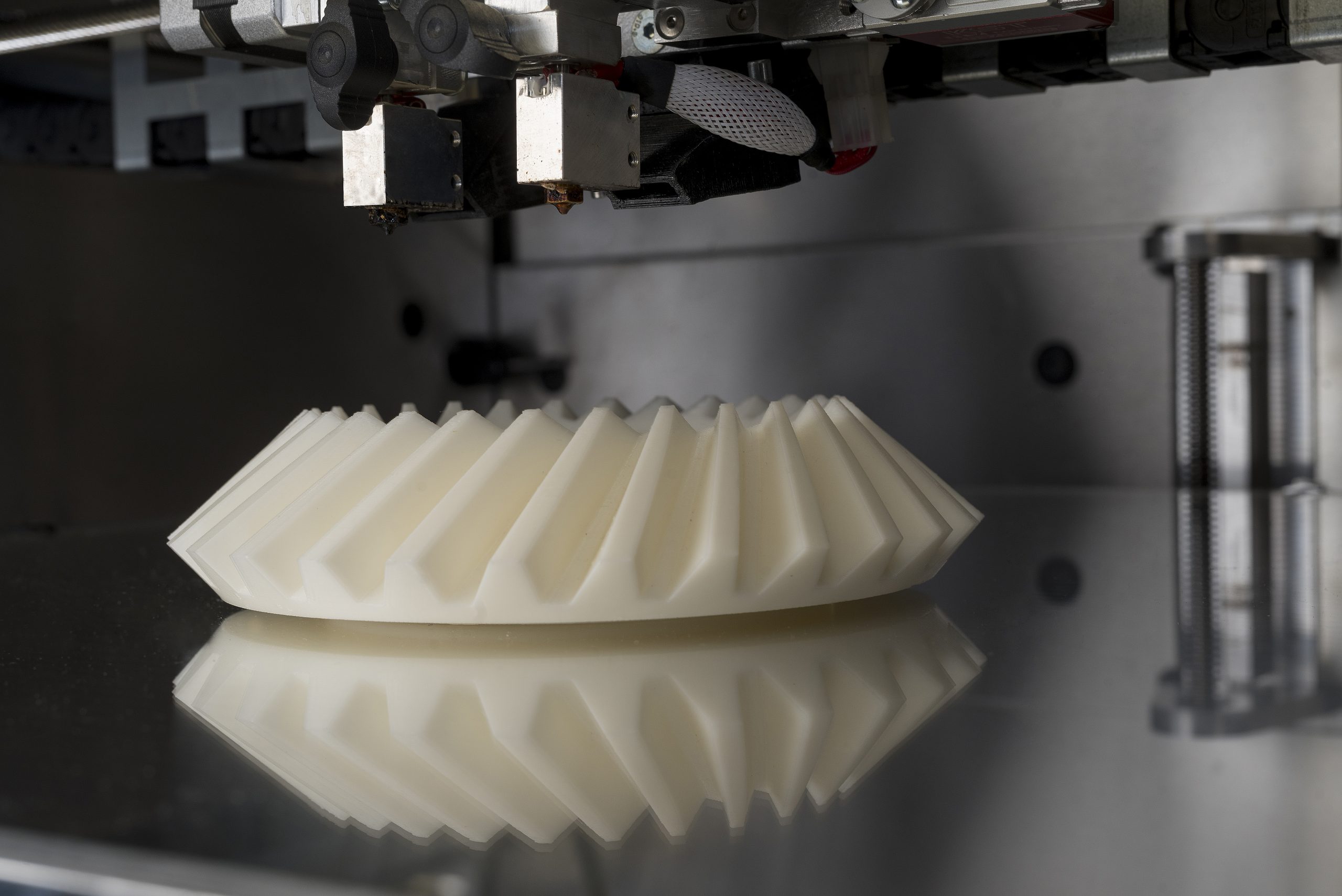

Defense applications often demand components of substantial dimensions. From UAV airframes to structural elements for ground vehicles, the ability to produce large-format parts in a single build is essential. Large-format 3D printers, like those offered by Omni3D, address this need by providing ample build volumes, eliminating the need for assembly and ensuring dimensional accuracy, especially while replacing mission-critical parts.

The Science Behind Heated Chambers

The behavior of polymers during the 3D printing process is complex. As the material is extruded, it undergoes a phase transition from a solid to a viscous liquid state. To achieve optimal part quality, it’s imperative to control the cooling rate to allow polymer molecules to properly align. This is where heated chambers come into play.

Heated chambers create a stable thermal environment, preventing rapid cooling that can induce internal stresses and lead to warping, delamination, or reduced mechanical properties. By maintaining a consistent temperature, the material has sufficient time to crystallize properly, resulting in parts with enhanced strength, durability, and dimensional accuracy. This is particularly critical when using high-performance polymers like PEEK, PEI, and ULTEM, which require precise thermal management for optimal results and that are currently used as substitutes to metals.

Real-World Applications

The combination of large build volumes and heated chambers empowers defense industries to tackle a wide range of applications, including:

- UAV and drone components: Produce large airframes and structural elements with complex geometries.

- Ground vehicle parts: Manufacture replacement or upgraded components for tanks, armored vehicles, and other ground-based equipment.

- Naval applications: Create large-scale prototypes and end-use parts for shipbuilding and maintenance. By investing in large-format 3D printers with heated chambers, defense organizations can enhance their capabilities, reduce reliance on traditional supply chains, and accelerate the development of innovative solutions.

Omni3D: Your Partner in Defense Manufacturing

Omni3D is at the forefront of large-format 3D printing technology, offering solutions tailored to the demanding requirements of the defense industry. Our printers are equipped with advanced features such as heated chambers and open material systems, enabling you to produce high-quality parts with confidence.