Aerodynamic studies on combat aircraft FA-50

In the age of technological advancement, 3D printing is becoming a crucial tool supporting the development of modern scientific and industrial research. A prime example of this is the collaboration between Omni3D, a company based in Poznań, and the Air Force Academy (LAW) in Dęblin. This partnership has resulted in the creation of a 1:14 scale model of the FA-50 aircraft, which serves as an integral part of a master's thesis focused on analyzing the aerodynamic properties of this aircraft.

Project Goal

The aim of the project was to create an accurate 3D-printed model of the South Korean FA-50 Fighting Eagle, which would be used for detailed aerodynamic testing in a wind tunnel. The aircraft is manufactured by Korea Aerospace Industries Ltd. (KAI), headquartered in Sanam-myeon. Pilots from the 23rd Tactical Air Base in Mińsk Mazowiecki will be flying these aircraft, making them a significant addition to the Polish Armed Forces. The research conducted on the model aims to deepen the understanding of the FA-50’s aerodynamic properties, helping to determine the fundamental aerodynamic characteristics and assess the forces and moments acting on the aircraft over a range of angles of attack and sideslip. Additionally, it will serve as an educational tool for engineers and scientists, aiding in the comprehension of complex aerodynamic phenomena and playing a key role in pilot training. The findings will be essential for future development and optimization of the aircraft model, potentially leading to structural modifications for performance improvements.

It was established that the FA-50 model would be made to a 1:14 scale, enabling experiments while maintaining proper aerodynamic proportions. This scale ensures the model is large enough to accurately replicate the aerodynamic features of the full-sized aircraft, yet small enough to fit within the available wind tunnel for testing.

Project Execution

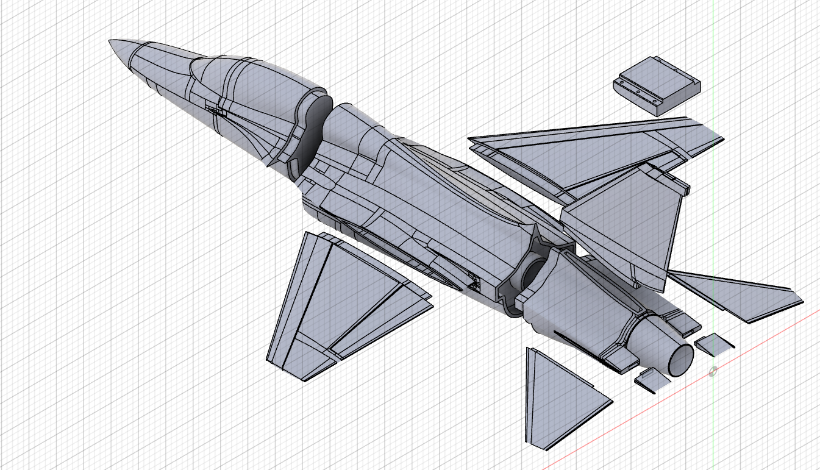

The Air Force Academy provided Omni3D with a digital version of the aircraft in the form of a 3D model. Omni3D was selected for the project based on their prior experience with similar tasks.

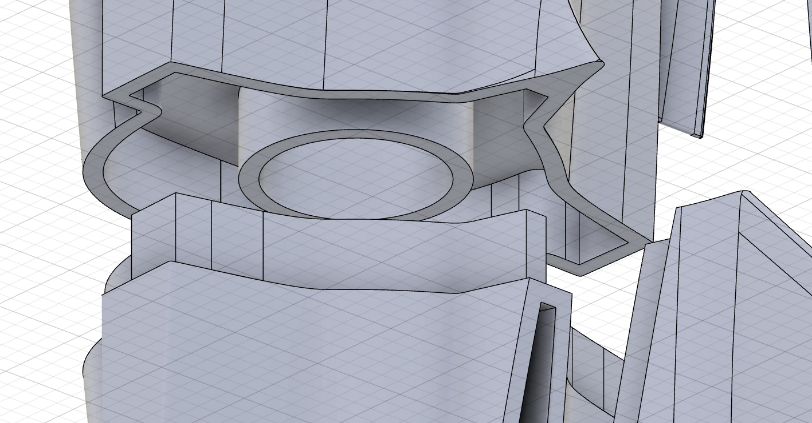

„Omni3D stands out for its professional approach to every project, carefully selecting the printing technology to ensure the highest quality and precision. Each detail is meticulously prepared, guaranteeing a perfect fit for all components. Thanks to a well-thought-out division of parts and practical joining systems, the final assembly of the entire model will be quick and straightforward.” – said Dr. Zbigniew Czyż.

In Poznań, at Omni3D’s headquarters, the process began with an analysis and preparation for printing, as well as the selection of materials. „”For printing this type of model, we typically recommend PLA or PET-G filaments. However, since the model was to be glued, sanded, and painted, we opted for ABS-42 filament, which, apart from offering high durability and strength, allows for such post-processing” – said Grzegorz Król, 3D Printing Specialist at Omni3D.

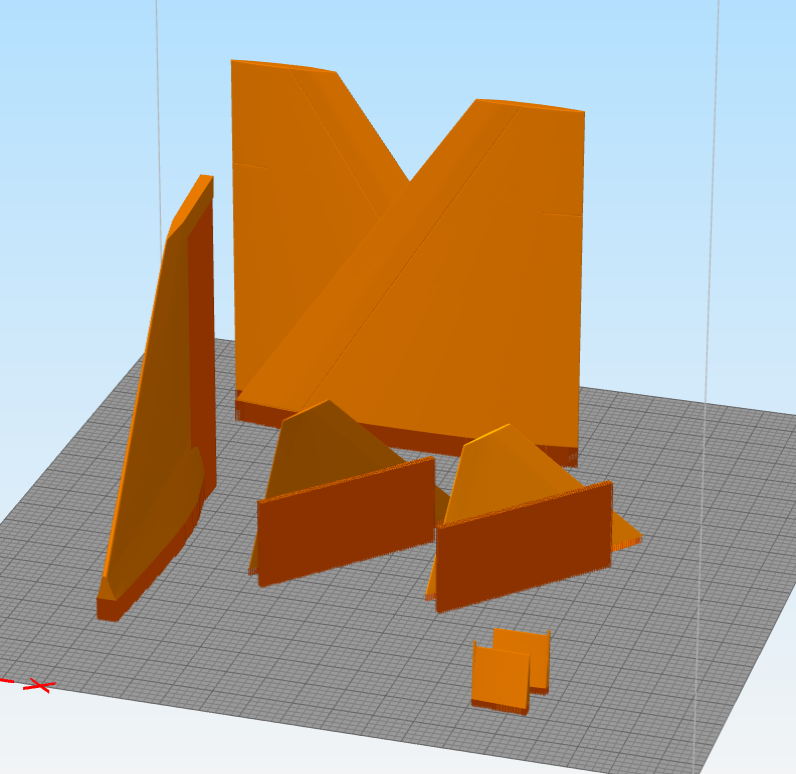

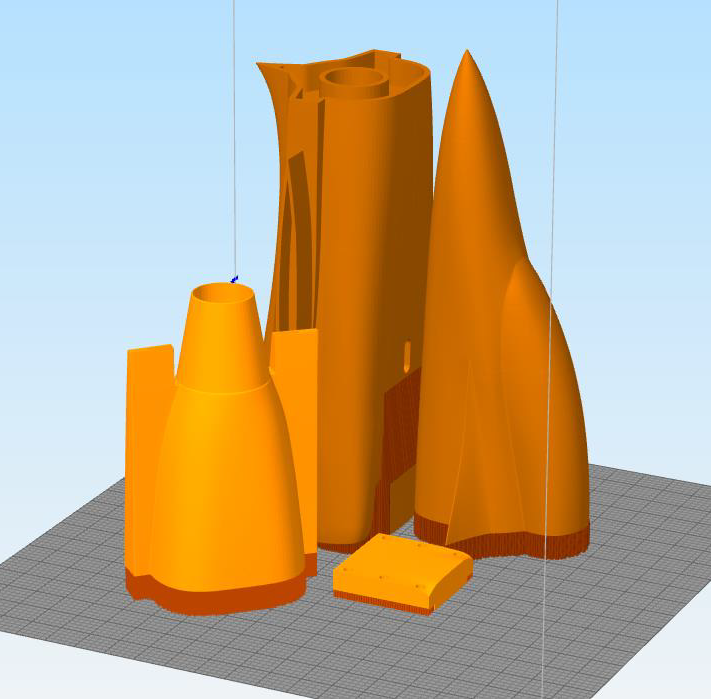

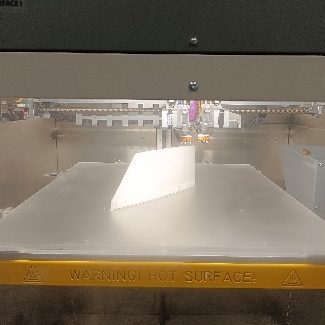

The model, measuring 100 cm by 70 cm, had to be divided into sections to fit the build volume of the Omni TECH industrial printer, which has a workspace of 500 x 500 x 570 mm. To accurately reproduce all details, two nozzle sizes were used. A larger 0.8 mm nozzle was used for the aircraft’s body, allowing the main large-format part to be both sturdy and precisely printed in a shorter time compared to using a 0.4 mm nozzle. The 0.4 mm nozzle was reserved for printing thin components such as wings and tail surfaces. Each segmented part was designed with additional tabs to increase the glue contact area with the material during assembly, ensuring durable and rigid joints.

The entire printing process took approximately five days.

The completed model was delivered to the Air Force Academy, where it will undergo additional post-processing. It will then be sent to the Center for Innovation and Advanced Technologies at Lublin University of Technology for wind tunnel testing. This facility simulates flight conditions, and the detailed measurements and observations conducted using the printed model will provide valuable data for analysis. We eagerly await the results.

Results and Benefits

The collaboration between the Air Force Academy in Dęblin and Omni3D has yielded tangible benefits for both parties. For LAW, it offers not only academic support for a master’s thesis but also the opportunity to use cutting-edge technologies, which elevates the quality of scientific research being conducted. For Omni3D, the project serves as an excellent opportunity to showcase the capabilities of innovative technologies in practice, potentially leading to further contracts and the expansion of cooperation with the military and academic sectors. We look forward to many more ambitious projects like this in the future.