Navigating Rail Filaments: Why Printout Certification Matters for Railway Additive Manufacturing

The railway sector is increasingly embracing additive manufacturing for its potential to revolutionize design, streamline production, and enhance maintenance. As the industry advances, so does the critical importance of material safety and regulatory compliance. For railway manufacturers, operators, and suppliers, understanding the nuances of rail filaments 3D printing and, crucially, their ultimate certification, is paramount. This post will provide an overview of railway additive manufacturing materials available today, while emphasizing a vital distinction that directly impacts the usability and safety of 3D printed components in railway vehicles.

The Essential Distinction: Material Approval vs. Printout Certification

A common misunderstanding in the market today is that a non-flammability approval of the material (filament) automatically translates to a non-flammability approval of the printout. This is fundamentally incorrect.

The process of 3D printing—including the specific printer, parameters, post-processing, and even the geometry of the part—can significantly alter the material’s flammability characteristics.

Therefore, a pre-print certificate from a filament manufacturer (e.g., Formfutura or 3D4makers for their base material) is meaningless and useless for railway applications. No railway manufacturer, operator, or company will install a 3D printed component if it does not possess the necessary safety approval for the finished print.

Understanding EN 45545-2: The Gold Standard for Railway Safety

Every railway vehicle operating under the UIC (International Union of Railways) standards must strictly comply with comprehensive non-combustibility standards, specifically EN 45545-2. This European standard for fire protection of railway vehicles outlines strict requirements for the fire behavior of materials and components.

- Certification Authority: The EN45545 certificate of non-flammability is issued by certification bodies, so-called accredited laboratories, following rigorous testing of the actual 3D printed part, not just the raw filament.

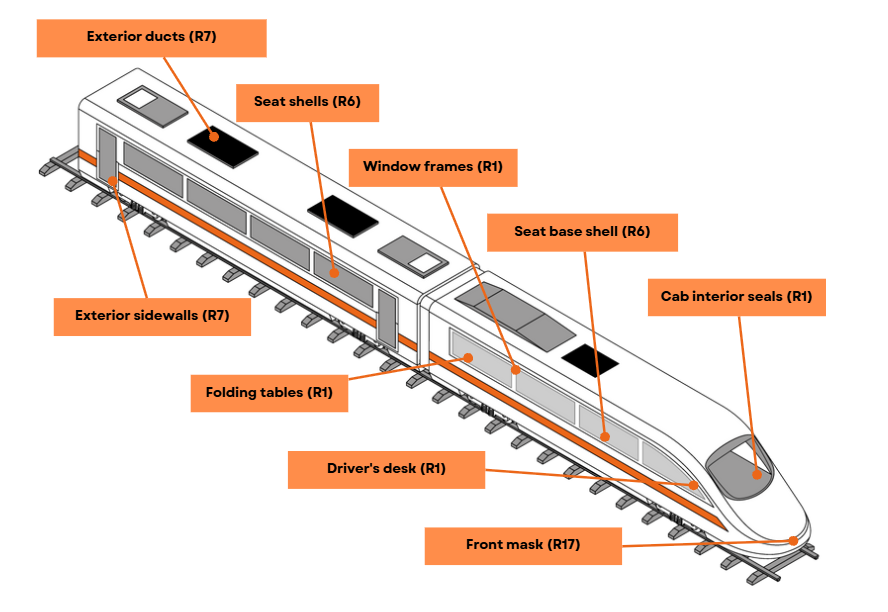

- Scope of Approval: The approval applies to specific hazard levels (HL1, HL2, HL3) and defined application areas (R1, R2, R6, R7, R17, R22, R23, R24, R25, R26). This detailed categorization ensures components meet the exact safety profile required for their intended use within a railway vehicle.

- Mandatory Compliance: Omni3D provides to all of our railway customers a non-combustibility certificate for the printed part, confirming its compliance with these stringent safety protocols.

There are rare exceptions where certification is not mandatory, such as for very small printed items (e.g., up to 60 grams for in-vehicle printouts, up to 200 grams for printouts outside the vehicle), but only if they are used in an already non-flammable environment, which is highly uncommon in most practical scenarios.

Download our brochure on railway

Why Certified Prints are Non-Negotiable for Railway Manufacturers

For companies engaged in railway vehicle interior parts 3D printing or any component destined for rail use, ensuring flame retardant 3D printing materials result in certified 3D prints for rail is not just a preference; it’s a regulatory and safety imperative. Without this final certification of the printed component, parts, regardless of material quality, cannot be legally or safely installed.

Omni3D’s Certified Solution for Rail Applications

Omni3D’s focus aligns precisely with the railway sector’s most stringent demands. Our interest is exclusively in enabling manufacturers to achieve EN45545 non-combustibility approval for the final 3D print. We understand that manufacturers are often approached with materials lacking this crucial final certification, which is why we emphasize transparency and compliance from the outset.

Our approach centers on providing industrial 3D printing solutions that not only offer design flexibility and optimization of the production process but, critically, guarantee the safety approvals necessary for the railway environment.

Main Benefits of Omni3D for Rail Additive Manufacturing:

- Guaranteed Safety Approvals: All our 3D prints undergo rigorous testing to secure non-flammability certificates at the demanding HL3 R1 and HL3/R6 levels. This certification encompasses not just the raw print, but also glued and painted elements, ensuring comprehensive usability in the demanding interiors of railway cars.

- Unmatched Design Flexibility: Our industrial 3D printers facilitate the rapid creation of prototypes and the production of highly customized parts. This capability allows for quick adaptation to individual design needs, accelerating innovation cycles while adhering to strict UIC compliance 3D printing requirements.

- Optimization of the Production Process: By leveraging industrial 3D printing for rail, our solutions enable the efficient production of parts with complex geometries. This leads to significant material optimization and cost reduction, all while maintaining high strength and full compliance with international standards for additive manufacturing safety rail.

See our solutions

Learn more about Omni3D industrial solutions for Railway applications

Request a quote for 3D printed EN45545 compliant components

Conclusion: Partnering for Reliable and Compliant Railway AM

The promise of industrial 3D printing for rail is immense, offering unprecedented capabilities for custom railway components 3D printing and optimized railway production. However, genuine value in this sector is intrinsically tied to certified safety. For railway manufacturers and operators, selecting a partner who understands and delivers on the critical distinction of EN 45545-2 approval for the final 3D print is essential.

Omni3D is committed to providing reliable, certified solutions that meet the highest safety standards, enabling you to confidently implement additive manufacturing for critical railway applications.