Faced with the challenge of safely transporting sensitive electronic components, BOSCH sought a reliable, fast and efficient solution. By partnering with Omni3D, they were able to develop a 3D-printed custom transport solution that met their specific needs and improved operational efficiency.

Project Overview

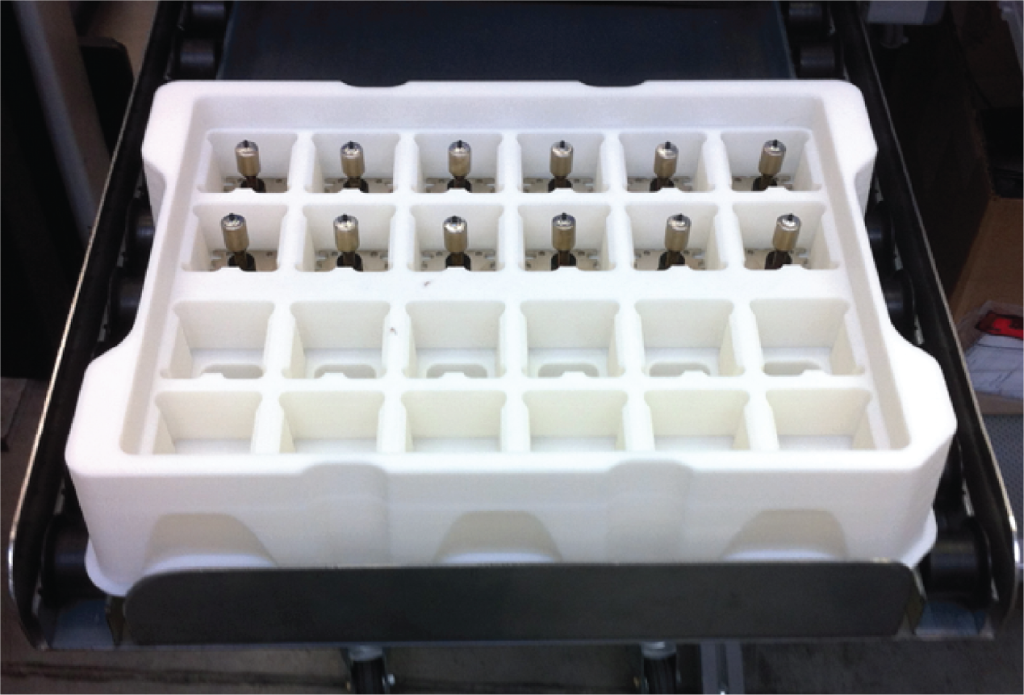

BOSCH’s main goal was to optimize the production process on one of their lines by designing a specialized tray for the safe transport of electronic components.

This tray needed to meet several critical requirements:

- Precisely fit the component dimensions.

- Lightweight for easy handling.

- Stackability with other trays to optimize space and ensure ergonomic transport.

BOSCH needed to validate the design’s accuracy before commissioning an expensive production mold. This is where 3D prototyping played a pivotal role.

Execution Process

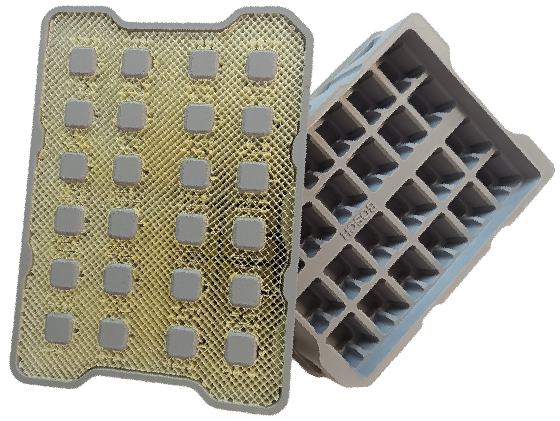

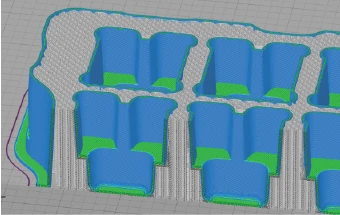

The model was printed on an Omni TECH printer using ABS-42 material and ODS-20 as a support material. The use of the soluble ODS-20 support material was particularly advantageous given the complex geometry of the model. Easy removal of supports after completion of printing eliminates the risk of damage to the model surface and increases the precision and quality of the details. This 3D technology enabled exact and swift adjustments even for complex shapes, meeting BOSCH’s high-quality standards.

“Our equipment consists of many components that we need to transport between production halls. The tray must be perfectly suited to the components and to our infrastructure to ensure safe transport. Thanks to prototyping, we can verify the design accuracy in real-time before moving to final production” explained a BOSCH representative.

Results and Benefits

Thanks to the 3D technology provided by Omni3D, BOSCH was able to assess the accuracy of the tray model and make necessary adjustments, leading to a final design that met strict requirements. Using the soluble support material ODS-20 allowed for high surface quality and dimensional accuracy, expediting the design refinement process and preparing it for final production. 3D printing enabled quick and economical adjustments, avoiding high costs from potential production errors in traditional manufacturing methods and streamlining the development of the final thermoforming mold.

Part Technical Details

| Material | ABS-42 and ODS-20 (soluble support material) |

| Print Time | 58 hours |

| Weight | 900 g |

| Dimensions | 360 x 260 x 75 mm |