Pre-purchase Testing Your Industrial 3D Printer is Essential

Investing in an industrial 3D printer is a significant strategic decision, transforming your production capabilities, streamlining workflows, and achieving tangible competitive advantages. Yet, for many, the leap into a new additive manufacturing technology can feel daunting. How do you ensure the technology delivers on its promises for your specific applications? This is why At Omni3D, we offer verification through rigorous testing and a comprehensive onboarding process. We guide our customers to be empowered and knowledgeable from your very first inquiry through seamless installation and full integration into your production workflow. A cornerstone of this approach is providing real-world 3D print tests on your actual parts.

Beyond the Brochure, a Tailored Print Test

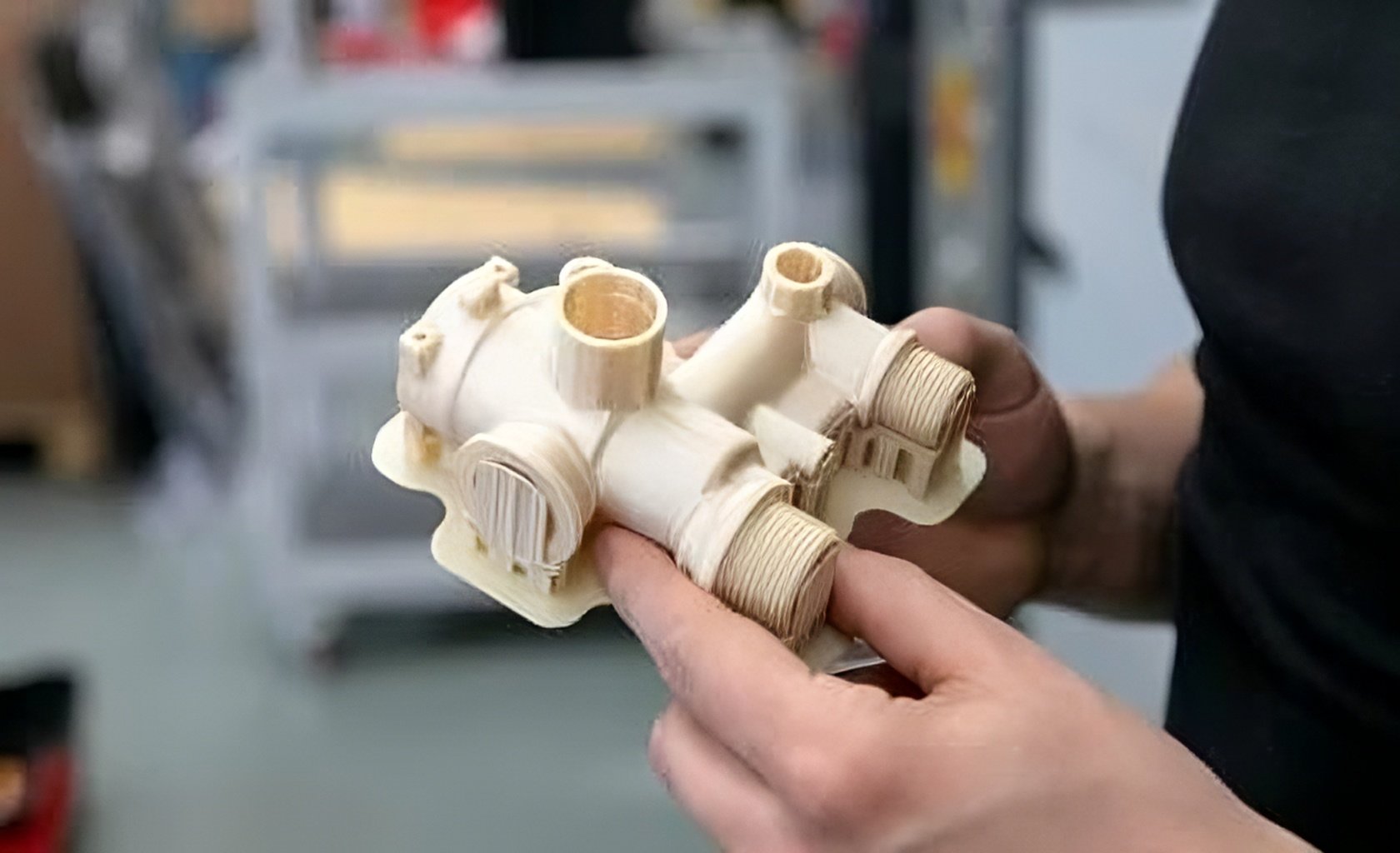

While specifications and features are important, nothing compares to seeing your own critical component come to life on an industrial 3D printer. This isn’t just a demonstration; it’s a vital, tailored evaluation that provides concrete, quantifiable data for your additive manufacturing technology evaluation.

Here’s why a custom print test is indispensable for your investment decision:

- Precise ROI Calculation: We move beyond theoretical savings. By printing your specific part, we can accurately compare the material consumption, printing time, and post-processing steps against your current manufacturing methods. This allows for a much more precise calculation of the Return on Investment (ROI) you can expect from integrating an Omni3D system. Understand how many parts you need to print to recover your investment, and the daily savings you can achieve.

- Validated Material Performance: Different industrial applications demand specific material properties. A test print allows us to validate the optimal engineering polymer or high-performance polymer for your application. We can assess its mechanical properties (e.g., tensile strength, impact resistance, heat deflection) under conditions that simulate its intended use, ensuring the material meets your exact performance requirements.

- Mechanical Stress & Functionality: Does the part need to withstand significant loads, vibrations, or extreme temperatures? A test print allows for direct evaluation of the printed part’s behavior under various mechanical stress scenarios. You can perform fit and function tests, ensuring the part performs as expected in its operational environment.

- Accurate Production Planning: Gain precise estimates for printing time for your specific components. This data is crucial for production planning, scheduling, and scaling your operations efficiently. No more guesswork about throughput – you’ll have data-driven insights.

- Uncompromising Quality & Repeatability: See for yourself the dimensional accuracy and surface finish capabilities of Omni3D industrial printers. Assess how consistently the Omni3D system produces identical parts, a hallmark of true industrial reliability. For critical applications, consistent quality means reduced waste and dependable performance.

Omni3D’s Commitment: We Partner with you from Inquiry to Integration

Our process is designed to empower you with confidence:

- Initial Consultation: We start by understanding your current manufacturing challenges, specific part requirements, and strategic goals.

- Application Analysis: Our experts work with you to identify the best materials and printing strategies for your components.

- Tailored Test Print: We take your STL file and produce your part on our industrial systems, providing a tangible output for your evaluation.

- Data-Driven Assessment: We present detailed data on material usage, print time, and potential cost savings, allowing you to perform a robust additive manufacturing technology evaluation.

- Seamless Integration: Once you decide, our team ensures smooth installation, comprehensive training, and continuous technical support, making sure your Omni3D printer integrates effortlessly into your existing manufacturing workflow.

We believe in no magic, just excellent professional engineering experts paired with industrial, reliable systems for the most demanding applications. This collaborative approach minimizes risks and maximizes the benefits of on-demand manufacturing.

What Should You Assess During a 3D Print Test?

When evaluating a test print, consider these critical factors:

- Dimensional Accuracy: Does the printed part precisely match the CAD model’s dimensions and tolerances?

- Surface Finish: Is the surface quality acceptable for your application, or does it require further post-processing?

- Mechanical Properties: Does the part exhibit the required strength, stiffness, flexibility, or other mechanical characteristics?

- Material Adhesion: Are the layers well-bonded, indicating robust part integrity?

- Weight Optimization: Can the design be further optimized for lightweighting without compromising performance?

- Support Structure Quality & Ease of Removal: Are supports effective yet easy to detach without damaging the part?

- Overall Print Reliability: Does the print complete without errors, reflecting consistent machine performance?

Ready for Your Free Assessment and Test Print?

Eliminate the guesswork and make an informed decision for your company’s future. Our sales team is ready to provide a free, no-obligation assessment tailored to your needs. Send us your STL files, and let us demonstrate the precision, reliability, and cost-effectiveness of Omni3D’s industrial 3D printers with a sample print of your own part.

Take the critical step towards optimizing your production. Contact us today for your free assessment and test print!