How to choose 3D printing technology for your application – guide

3D printing is the future of the world - not only industrial, it can also be a part of our everyday lives.

From many 3D printing technologies, it is difficult to choose the one that will be appropriate for a given application, i.e. the product that we want to finally receive. In the following publication, I will try to explain the methodology of these most popular methods and indicate their main features that will help to guide the right choice.

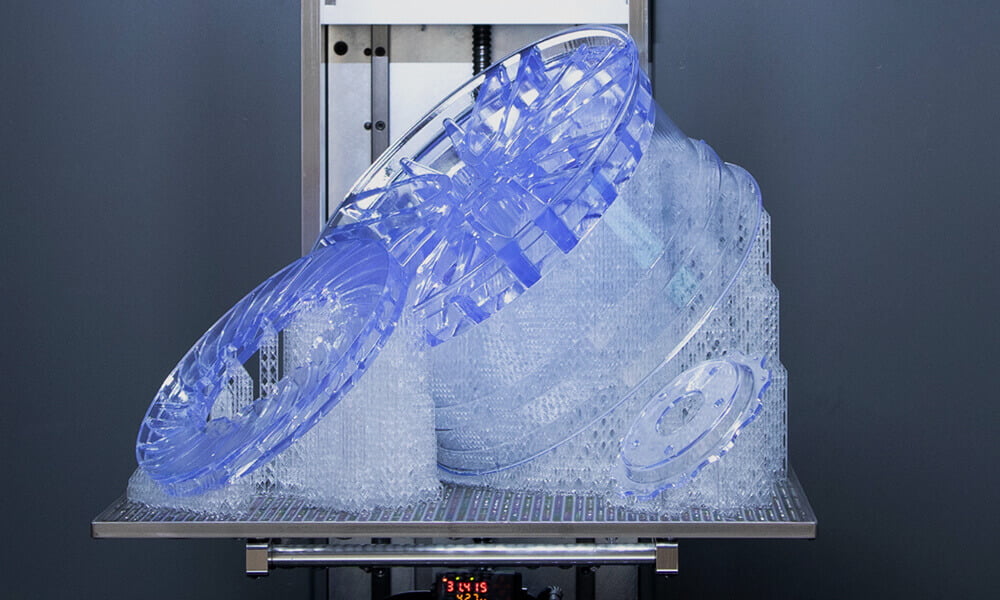

1. Stereolithography (SLA)

- It was created in the 1970s in Japan – popularized since 1986 by Charles W. Hull – the founder of the 3D Systems.

- A process based on photopolymerization with the use of a laser.

- Main features: speed, reflection of details.

Source: ipfl.co.uk

The SLA printing technology is based on printing from polymer resins. In addition to the above-mentioned features, the prints are isotropic, which explains their durability – the same in all printing axis. In addition, the individual layers of the print are bonded into a tight structure, which allows the elements to be considered waterproof, while the smoothness of the surface allows the use of SLA printers in any industry where these properties are important. Unfortunately, this technology is not indifferent to the environment and the user. Its limitation is also the necessity to harden the printed elements – in order to obtain maximum strength. It also determines the size of the printed objects, which are rather limited to small sizes.

Most often used in:

- Dentistry

- Stucco / Small design

- Jewelry

- Small industrial parts – great for printing PCBs for electronics

- Medicine – incl. biocompatibility materials

- Fashion

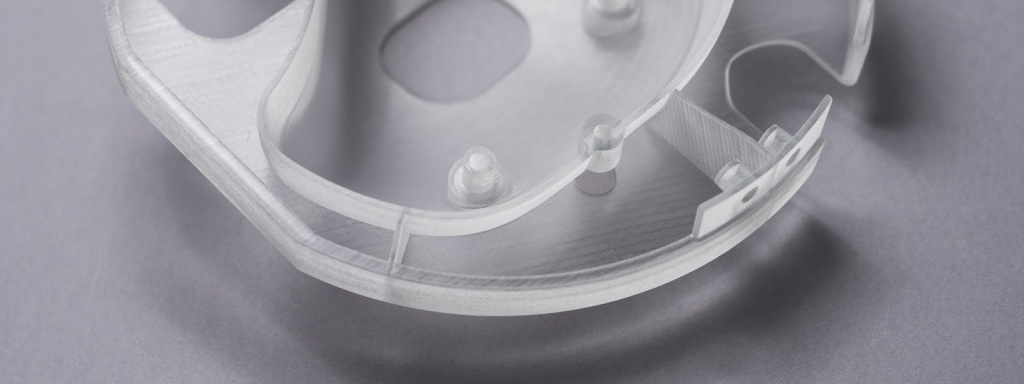

2. Low Force Stereolithography (LFS)

- I was shown to the market at the end of the previous decade, and it became popular in 2021.

- Improved SLA process – characterized by greater precision in printing details – popularized by Formlabs.

- Main features: speed, detail reproduction, more refined printing system compared to the classic SLA.

Source: additive-x.com

As a related and advanced form of SLA technology – it has the same uses. However, thanks to the increased printing parameters and the possibility of e.g. reducing the contact points of the printout with the support element, it gives the possibility of obtaining an even smoother surface immediately after printing.

Most often used in:

- As in SLA – with a strong emphasis on jewelry and dentistry

- Audio industry – components of earphones

3. Digital Light Processing (DLP)

- The history of this methodology begins in 1987 – thanks to an invention made by Larry Hornbeck.

- Process based on photopolymerization (VAT POLARIZATION) – thanks to the use of UV light.

- Main features: speed, resolution of small prints.

Source: wevolver.com

3D printing technology based on similar principles as SLA, but in this case the resin is cured with UV light. The projector’s resolution, height or the distance of light from the layer (print size) determine the quality of the surface. However, the big attribute of DLP is that the entire layer is cured simultaneously, which makes this method very fast.

Most often used in:

- Medicine

- Stucco / small design

- Dentistry

- Marketing / small gadgets – e.g. figurines, key rings etc.

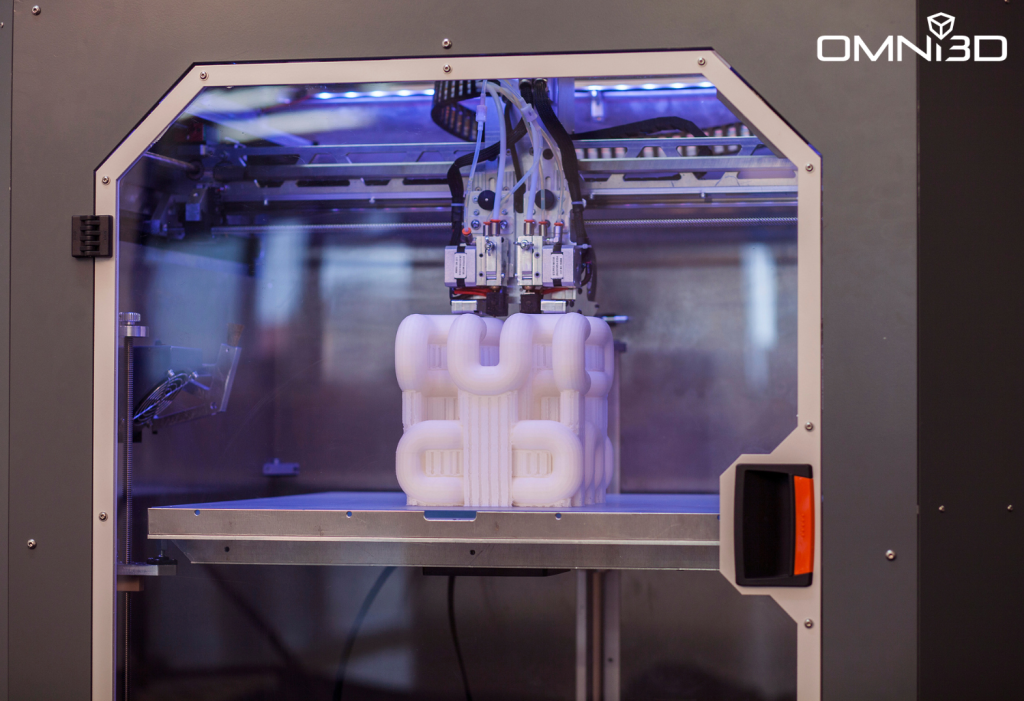

4. Fused Deposition Modeling (FDM/FFF)

- It was created in the early 1980s by Scott Crump and was distributed by his company – Stratasys.

- The process is based on the extrusion of plasticized polymer layers and is based on the thermoplastic characteristic of the materials.

- Main features: simplicity of basic processes, universal application, easy availability of raw materials.

Source: omni3d.com

The extrusion of plasticized polymer builds layer by layer the model set by the user. A manifestation of this is the characteristic appearance of prints, however, the visibility of the layers reduces in the case of industrial devices and some more engineering materials (PP, PA) . The uniqueness of this method is the full freedom to adjust the print parameters to the needs of the application. We are not just talking about hundreds of different materials, the properties of which can suit the needs of every user – from flex materials to very hard and resistant to many adverse environmental factors. Also, the printing methodology itself may be strictly determined by the operational needs. It is also one of the first methods in which it is possible to use two or more materials in one process (most often the base and support material – broken or soluble). FDM is also characterized by the freedom of setting the model during printing, which makes it possible to adjust the strength properties to the utility needs of the project.

Most often used in:

- All industrial sectors – automotive (ABS), aviation industry (PEI, PEEK), heavy

industry (PEKK, PEEK) - Medicine – preoperative models, biocompatible materials

- Architecture – models, visualizations, design

- Maintenance – spare parts, tooling etc.

- Hobby applications

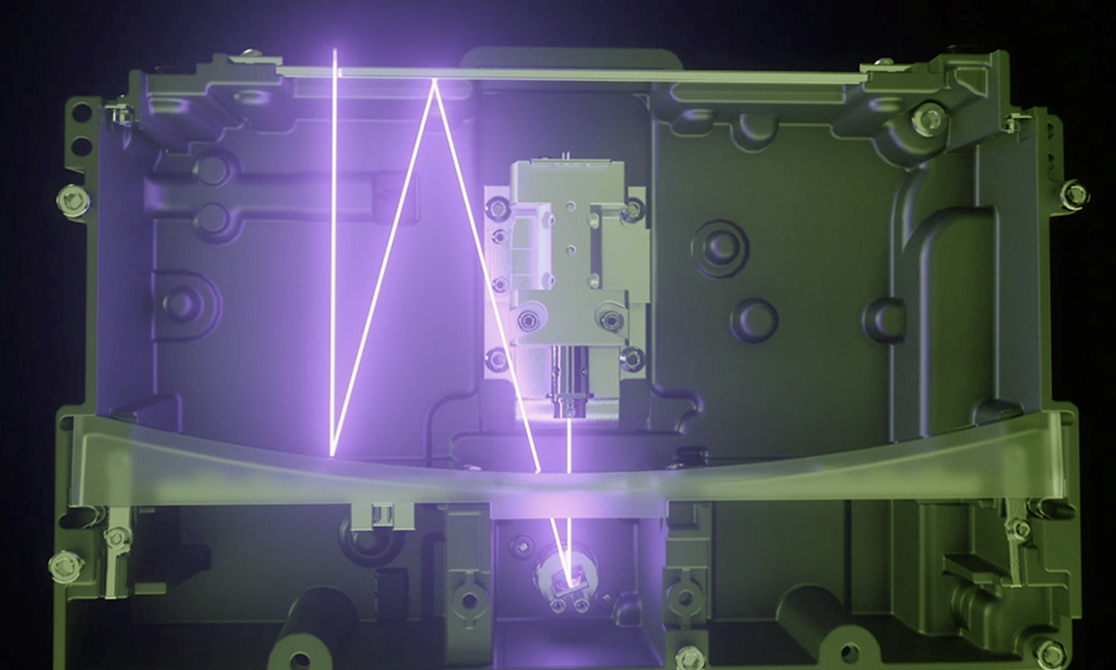

5. Selective Laser Sintering (SLS)

- The first appearance of this technology was in the mid-1980s – thanks to the development and patent of Carl Deckard and Joe Beaman, but the first non-commercial patent was created in the previous decade – In 1979.

- Technology based on sintering powdered material (plastics – polimers) in a powder bed fusion.

- Main features: no need for supports (the sintered powder itself is the support), detail reflection and dimensional accuracy.

Source: sinerit.com

Technology in which the tank is gradually filled with powdered polymer layer by layer. At the same time, the places that will be sintered are heated. Then, a high-temperature laser beam sinters specific layers of the printout. An important element in this technology is the powder, which is both the base substance and the support material, and protects the printout against possible deformations (although not completely – both shrinkage and layer hemming can take place). Therefore, this technology is characterized by very high accuracy, minimization of post-processing (no imperfections at the support) and freedom of design. The drawback is the need to prepare the process room and the user – as the SLS methodology is not indifferent to health (definitely more than other 3D printing technologies).

Most often used in:

- Medicine

- Engineering – eg housing

- Small production – small parts, also moving parts with complicated geometry (SLA, DLP do not provide this possibility)

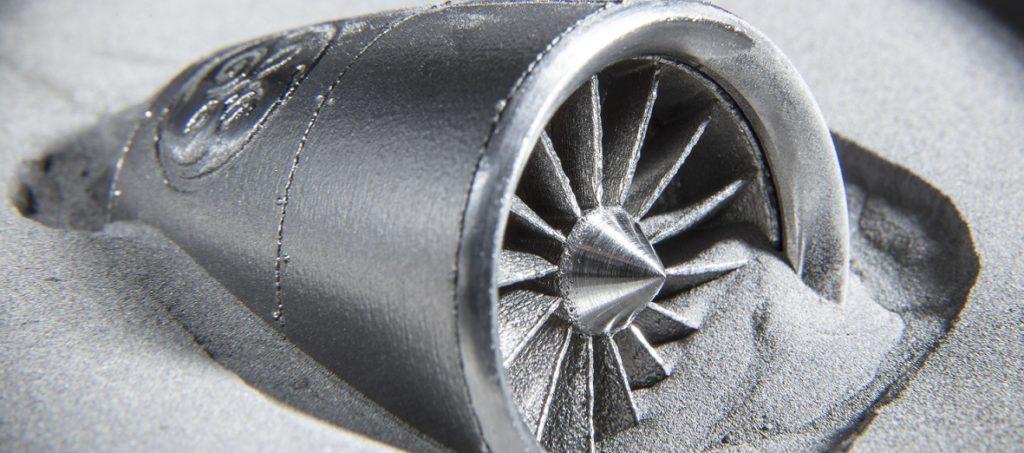

6. Selective Laser Melting (SLM)

- Established in 1995 in Aachen, Germany.

- Like SLS, it works by sintering the powder using a laser, but in this method the laser beam is designed to liquefy the powder. The second difference is that the powdered material is metal (niche: ceramics).

- Main features: print precision, post-processing minimization, metallic or ceramic production substances.

Source: wdoose.de

Thanks to the possibility of using metallic or ceramic substances, this method has opened the door to the use of 3D printing in the aviation and space industry. It also made it possible to appear in consumer industries – such as food industry – thanks to the possibility of printing from stainless steel. It is still a niche methodology, mainly due to the high investment cost, expensive materials and very expensive and difficult operation. However, introducing it into the world – made it possible to show the power of 3D printing and use the process t significantly improve production elements, through, among others, reducing their weight and geometric optimization of designs.

Most often used in:

- Aerospace industry

- Food industry

- Oil and Mine Industry / heavy industry/ construction industry

- Jewelry

- Arms industry

7. Electronic Beam Melting (EBM)

- The world saw it for the first time in 1993, but it was popularized in 1997 thanks to the company Arcam AB. In 2016, the company was acquired by GE and is known as GE Additive.

- A method similar to SLM, but here a high-energy beam of electrons in a vacuum environment is used to combine metallic powder.

- Main features: high resistance of printed elements, printing from metallic powders (mainly titanium).

Source: engineeringproductdesign.com

This methodology is very similar to SLM – however, thanks to the use of an electron beam and a vacuum, unnecessary stresses are not created in the printed element, which increases the possibility of printing elements, e.g. more fragile. An additional advantage – enabling the emergence of these technologies, e.g. in the space industry – is the reduced level of oxidation, which affects the possibility of their adaptation in confined spaces – while minimizing the need to introduce security measures such as in other methods of printing from metal. It is a very expensive technology and at the same time still limited in terms of materials, additionally characterized by lower printing accuracy than SLM – but it is faster.

Most often used in:

- The space industry

- Defense Industry

- Aviation industry

- Medicine

8. Laminated Object Manufacturing (LOM)

- The origins of this methodology date back to 1991 and the work of Helisys, but the technology itself was commercialized by Mcor Technologies – the MacCormack brothers.

- LOM consists in arranging layers covered with adhesive material and cutting them with a laser (mostly new solutions) or knife.

- Main features: possibility to use equal laminating materials – paper, plastic, metal, ceramics, etc., multi-color printouts.

It is a methodology that is based on the simplest of all professional principles, which makes it one of the cheapest and fastest to implement methods. At the same time, its versatility makes it possible to make models similar to those obtained in SLS and SLA technology. In this case, the „resolution” of the model is determined by the layer thickness. An additional advantage is the possibility of adding elements during the process – e.g. arranging electrical bundles or sensors. All this thanks to the lower temperature of the process itself. The distinguishing feature of LOM is the ability to use several colors in individual layers, which makes this method ideal for printing visual elements. Unfortunately, a very important element of this methodology is the material used – its quality determines the necessity or lack of post-processing. Additionally, the substances sticking the layers together significantly affect the quality and lifetime of the prints.

Most often used in:

- Design / architecture

- Electronic industry

- Prototyping

9. Binder Jetting (BJ)

- The history of this technology dates back to 1993 and the American MIT university of technology. However it was distributed by the Extrude Hone Corporation in 2005.

- The technology is based on gluing the powdered material with a binder. A characteristic feature of this methodology is the necessity of hardening and, at a later stage, sintering the printout.

- Main features: up to 40 kg of print per hour (really fats), minimization of environmental influence on the process (minimization of warping and shrinkage), possible multi-color printing.

Source: exone.com

Contrary to previous technologies, this method is based on dispensing the adhesive into a very fine (0.05 mm) powder. As a result, the „resolution” of the printouts is very high. In addition, printing takes place at ambient temperature, so the prints are not exposed to deformation. Printed elements, however, need two additional processes that will result in obtaining the final result – these are curing and the sintering process. The advantage of Binder Jetting is the ability to work with various materials – such as metal, sand, ceramics without the use of supports and with materials of various colors. This method is also characterized by an incredible printing speed, and due to the lack of influence of the environment on the printout, we can produce much larger elements in one printer.

Most often used in:

- Foundry (molds and cores)

- Design / architecture

- Multicolor prototyping

- Printing from „sand”

- Medicine

10. Material Jetting (MJ)

- The technology began in the mid-1990s when SolidScape commercialized 3D printing

technology through wax spraying. - The technology is based on spraying successive layers with the base material.

- Main features: printing precision up to 10mic, possibility of using different materials (colors) in the same layer.

Źródło: hubs.com

It is one of the most expensive methodologies, but also one of the most effective and fastest, while maintaining the highest possible accuracy. A characteristic feature is the possibility of printing transparent elements, which is impossible in the case of other 3D printing technologies. It is not a method without the need to build support structures, but thanks to the use of soluble supports, it has the ability to create elements with very complex geometry.

Most often used in:

- Medicine – dentistry

- Automotive – e.g. lamps

- Architecture / design

- Rewelers and stucco

I know that not all of the technologies are mansion in the this publication but I hope that this text will give you the opportunity to better understand the maze of technologies that create the biggest part of 3D printing world. If you want to ask about something – contact us any of the companies mentioned above.

Contact:

LinkedIn: Tomasz Garniec

m. +48 886 618 588

e-mail: tg@omni3d.com