The industrial 3D printing ecosystem – what is it?

3D printing is a viable manufacturing alternative with great potential. The intense growth that 3D printing experienced at the end of the first decade of the 21st century put the idea of a viable alternative to downsizing technology in the minds of some. It can be said that 3D technology came at the most opportune time, when the crisis of the early 21st century changed the "thinking" of many entrepreneurs. Since then, every additional cost has been analyzed, and companies have increasingly sought to minimize the risk of them. 3D printers fired the imagination of manufacturers, who finally got a tool that reduces material costs and the generation of "waste." A viable alternative has become one of the key elements of the development strategy of many companies in the automotive or product design sectors. 3D printing changed the prototyping process, which has since become simpler, faster and cheaper. However, as new possibilities were discovered, the industrial user began to demand more.

Ecosystem – getting out of the prototyping zone

An ecosystem is a collection of tangible and intangible factors that work together in harmony to optimize the performance of the whole. In industrial 3D printing, the ecosystem determines the optimal use of potential. Its components are not only hardware elements, but also knowledge, process preparation, post-process preparation and processing, etc. The further we move away from „prototyping,” the greater the importance of other elements of the overall process. Today, the biggest challenge of the entire industry is to stabilize the ecosystem in such a way that it can meet the needs of as many industrial users as possible while managing as many aspects of its work as possible. In the following, I will focus on defining and describing the basic components of the modern industrial 3D printing ecosystem.

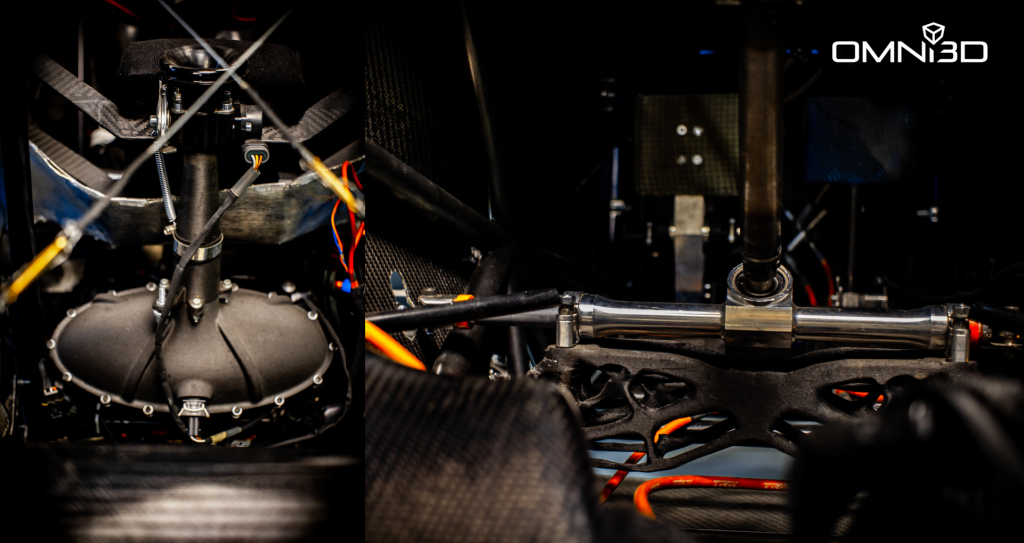

Collector & steering gear mounting printed on Omni3D printer and installed in racing car.

Material and equipment education is key to taking the next step

At the core of the theory of working with professional 3D printers is education. What’s more, it’s not enough just to know about the printer, its design or software – when entering the world of industrial 3D printing, knowledge of the material we will work with becomes important. Without directional studies, it is difficult to gain complete knowledge, and even sometimes they are not enough to achieve sufficient qualifications to print unhindered from all materials. This is why in the world of 3D printing such an important function is performed by companies that provide 3D printing service and technological advice. This is where knowledge development is fastest and easy to condense into a form acceptable to users. The concepts of shrinkage, layer adhesion, warping, infill, layer height, oozing, raft, seam and many others also related to the design process are elements that every user should assimilate. He needs to learn about their properties and parameter variation, which depends on the size, geometry, material and other components of the 3D printing process. The more knowledge a 3D printing user has, the more efficiently he can navigate the technological aspects and the more he can optimize or even maximize the use of 3D printers.

Designing for 3D printing – another dimension, another look

Another indispensable part of the ecosystem and a continuation of 3D education is a different perspective on proper model preparation and design. In this regard, there is some dissonance between expectations and manufacturing realities. Like any technology, 3D printing currently has some limitations that sometimes affect the expected results. Reconciling every component point is not possible, but a user who has knowledge of the material and equipment he or she will be using is able to set the parameters of the model to optimize it in every respect. What’s more, 3D printing offers a wonderful opportunity to make a component according to requirements – the right resistance, surface quality and speed of manufacturing – all of which are possible, striking a balance between expectations or selecting the component that is crucial and significantly improving its properties in that particular aspect. The performance features are among the first and basic questions that any vendor should ask a prospective user. They determine: the knowledge he should possess, the device he should operate and how he should use the model after it is printed.

Material – the key to success in the world of 3D printing

In the current world, there are hundreds, if not thousands, of materials for 3D printing. Each of them has different properties both manufacturing and determining their final use. Manufacturers boast blends that affect the ease of printing and give a given material certain unique parameters such as non-flammability. Choosing the right material should be the basis for implementing 3D printing – but it should be remembered that determining even the ideal one will not ensure stability and repeatability of the process at 100%. That is why it is so important that in addition to selecting all the parameters of the material – it is also necessary to set up internal procedures so that the material maintains its original properties for as long as possible. Many times it happens that users are unable to repeat a previously successful process – due to poor storage of the material or a change in its parameters by the manufacturer. In this aspect, even the smallest parameter can make a difference – because it determines the secondary analysis – of the composition, properties and capabilities of the device. Manufacturers are also increasingly paying attention to the regularity of the material that is processed on their equipment. Brendering, profiling of materials, or closing systems is just one aspect. Another trend is the development of the market for equipment equipped with drying (climatic) chambers, or the development of external equipment itself, which slows down the process of material degradation – ensuring a greater likelihood that a given print will come out again and again.

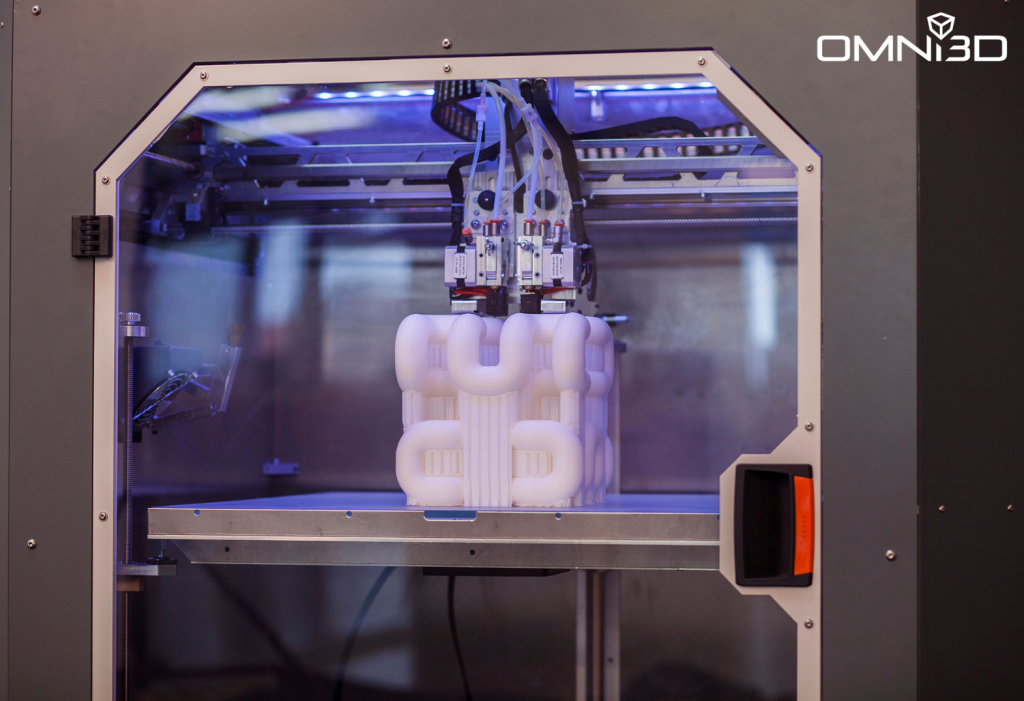

3D printer – tailored to your application

Closed desktop printer, open printer, professional printer, engineering printer, industrial printer, each has limitations. There is no hardware that will meet the needs of every user and every application. The choice of the right one should be determined by the application and the level of knowledge of future users. The goal of building an industrial 3D printing system should always be to optimize its performance – in terms of production and cost, as well as investment risk. It is also important to remember that in the case of 3D printing, which is still a technology of the future and which is constantly developing and adapting to the needs of increasingly demanding customers, investing „for the future” should not be the key element – because tomorrow there will be something new. With each new installation, each new application, often a print and a new material, users are breaking down the little barriers that push the additive world forward, changing it from the day before.

Printed and ready to use

In the world of 3D printer users, the perception of the printing process as something that corresponds to the realities of the printing itself and the process of drying the prints has become established. However, it is a much more complex concept that is becoming an increasingly important component in industrial 3D printing. Very often a printed part, must undergo further processes that will determine its final use. From the aforementioned „proper” cooling, through elimination of supports, cleaning of the print, coating, painting, curing, or firing. Each of the aforementioned elements is a product of the material used, the model designed, the printer and the type of application in which we want to use the model. Adding more post-processing elements significantly increases the possibilities and range of applications in which the elements can be used. At the same time, it should also be mentioned that at the same time, the level of material and hardware knowledge must increase in order to optimize the entire broad ecosystem.

Final test – product qualification

The ecosystem performs an additional function that for many industrial manufacturers is a key element of modern manufacturing. Ecosystem – defines and describes the process and optimizes the product at each stage. The result is the receipt of a print/product with the parameters as intended – that is, it gives the opportunity to standardize the product in terms of quality. A well-composed ecosystem can give confidence in the safe use of the final print – and thus certify the entire manufacturing process.

Lamp prototype for a new sports car model from Arrinera S.A. company – printed on Omni3D printer.

Ecosystem disruption – a path to innovation or failure?

Like any modern technology, evolving every day, it needs a fresh new look for every new component. 3D printing appreciates innovators and risk-takers who push the boundary every day. In industrial terms, this is an element that can lead to failure. The legitimate question then is – how should the ecosystem function in industrial realities. Each expansion of the ecosystem, each new attempt should be the initiation of a process that would include an analysis of the material, the device, the necessary post-processing activities, but also an analysis of the risks that such a move – beyond the defined and proven ground – may bring. The answer may be different in each case, which does not mean that it cannot be done. It just has to be done within a well-defined process.

The industrial 3D printing ecosystem has much more potential than it might have seemed just a few years ago. With the increase in knowledge, development of equipment and materials, more and more manufacturers are inclined to implement 3D printing, which means not just selling a printer – but implementing 3D – that is, the Industrial 3D Printing Ecosystem.

At Omni3D, we have nurtured the comprehensiveness of our services from the beginning, putting maintaining the right way to implement 3D printing first. Many years of experience gained by working with major companies around the world have made the process refined and guaranteed a seamless entry into the world of industrial 3D printing.

We provide:

- Multidimensional pre-implementation audit.

- Selection of the right printer – for the given application.

- Assistance in establishing internal processes.

- Selection of the right product eco-system components – from printers, to filaments, filament dryers, washers, or climate cabinets.

- Technology support.

- Service support.

- A series of training courses to continuously improve user skills.

LinkedIn: Tomasz Garniec

m. +48 886 618 588

e-mail: tg@omni3d.com