PC-60: a filament that combines strength with high temperature resistance

PC-60 (polycarbonate) filament is an engineered material successfully used in FFF technology.

Polycarbonate (PC) is an amorphous material characterized by a number of properties, such as transparency, bio-compatibility, good weather resistance and high impact strength. Its special feature is its low flammability, as it spontaneously extinguishes on ceasing contact with a flame. It has found its use in items such as halogen lamps, fairings, solar panels, CDs and DVDs and many others.

PC is one of the advanced industrial thermoplastics and is characterized by its extraordinary strength. It is designed for printers working with 1.75mm diameter materials.

Here are the characteristics and applications of the PC-60 filament:

Characteristics of PC-60 filament:

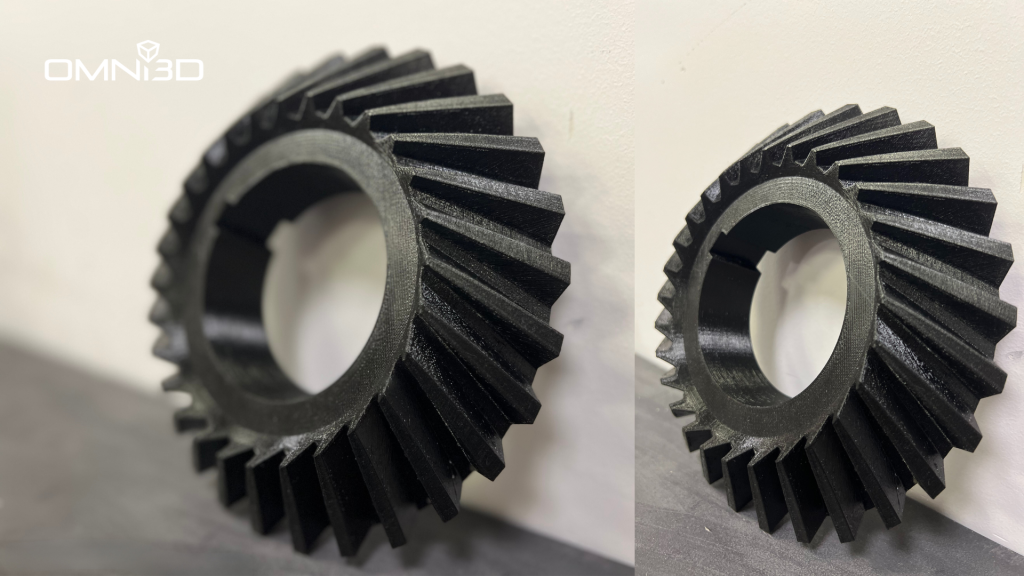

- Mechanical strength: PC-60 filament is characterized by its high strength, which means that printed objects made from this filament are strong and resistant to breakage. It has a tensile strength of 60.4 MPa and a Young’s modulus of 1462 MPa.

- Slight anisotropy of properties: No matter how the model is placed on the work table, it will have a similar strength. Typically, prints are weaker in the vertical direction than in the horizontal direction. For this material, the difference is less than 1 MPa.

- Impact resistance: PC-60 has very good impact strength, which means that the printed parts are resistant to cracks and sudden impacts. In a charpy hammer fracture test, a sample made of this material did not break.

- Temperature resistance: polycarbonate has a high operating temperature of up to 120℃. This makes it able to withstand demanding applications. The deflection temperature under a load of 0.45 MPa for this material is 143 ℃.

- Flame resistance: polycarbonate is a material with limited flammability. PC-60 has a flammability rating of V2, making it suitable for use in the electrical and electronics industries.

- UV resistance: PC-60’s composition gives it greater UV resistance compared to competing PC filaments.

Use of PC-60 filament:

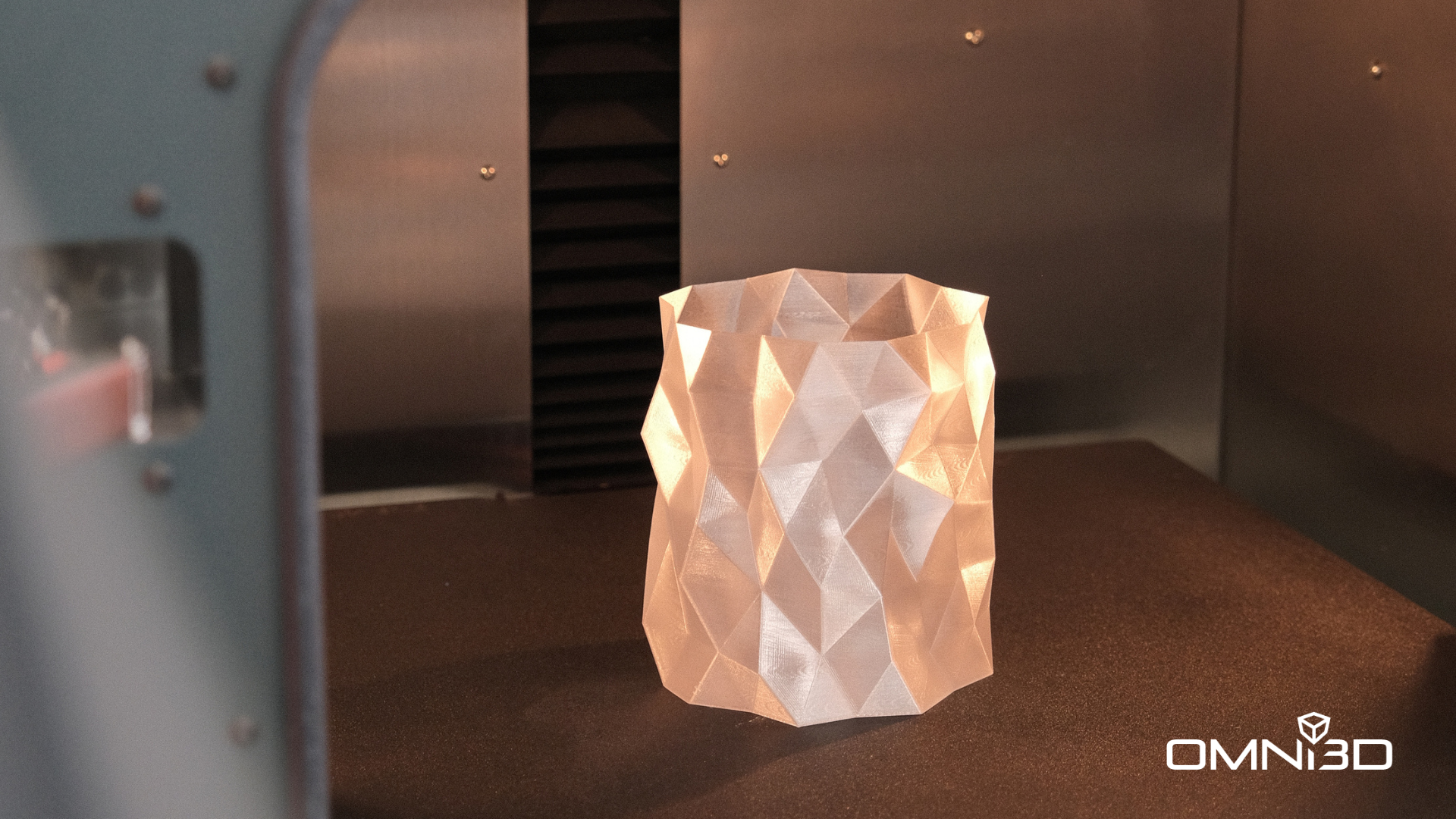

- Functional prototypes: PC-60 filament is widely used for prototyping as it is an admixture-free filament, allowing functional and visual testing.

- Final products: Thanks to its very good impact resistance, PC-60 filament is often used to print housings, covers and other parts that require high durability.

- Medical devices: PC-60 filament is also used in the 3D printing of medical devices such as prostheses, anatomical models, diagnostic tools thanks to its sterilization capability.

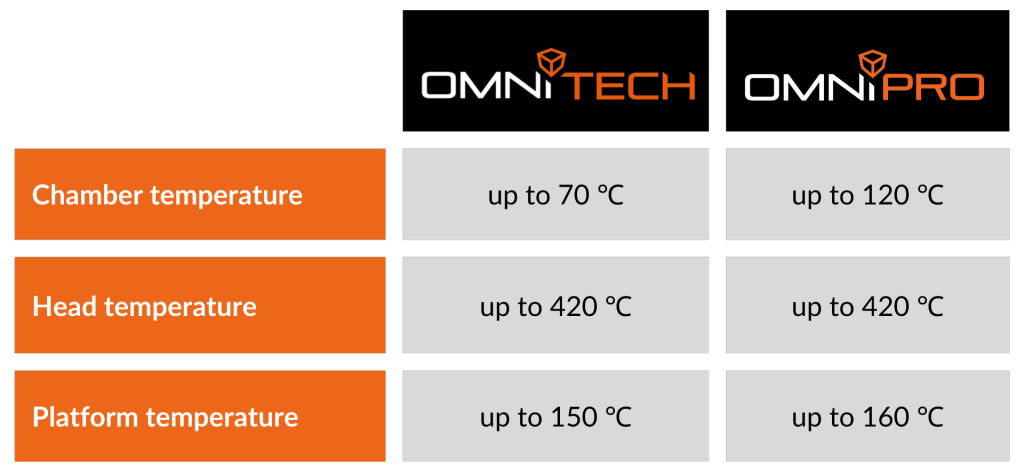

It is important to remember that PC-60 is an engineered filament for which it is necessary to have a printer that has an actively heated chamber and has a head that heats up to at least 280°C, which is achievable with Omni3D printers.

Contact:

LinkedIn Wojciech Wiśniewski

e-mail: wwis@omni3d.net