Preparing a 3D model for printing – the most common problems

Preparing a 3D model for printing can be difficult and challenging for both beginners and experienced printer operators. Here's a list of common issues that appear during the printing process that we recommend paying attention to.

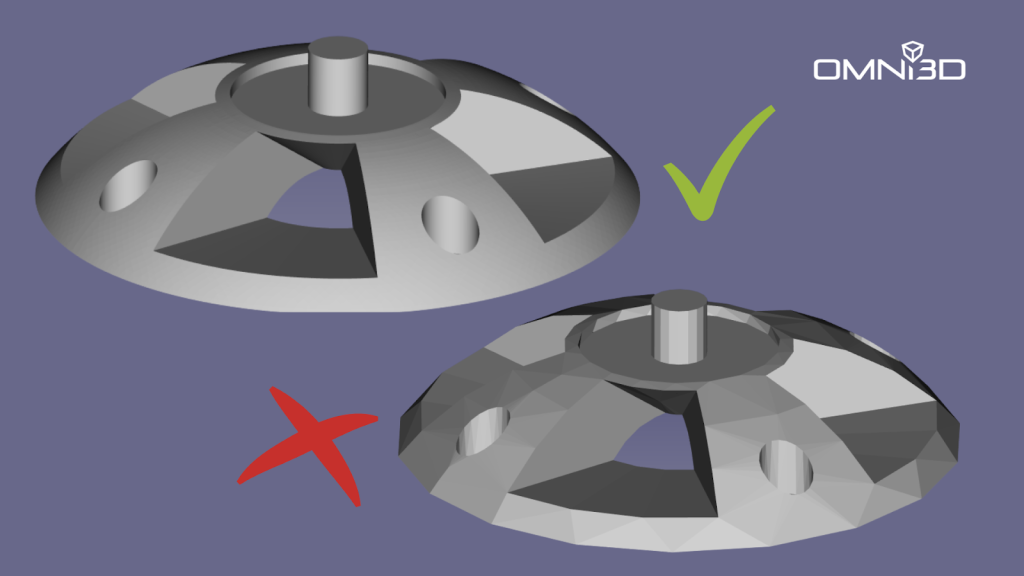

Lack of sufficient accuracy

The 3D model must be properly exported from the CAD program so that the slicer can properly interpret it and prepare commands for the printer. It is worth paying attention to the quality of the exported model set in the CAD program. High-quality models allow you to get the best results. It may happen that instead of round holes, the model has octagon-shaped holes. It is also important that the model forms a continuous, closed solid. Otherwise, the path generation software will not be able to interpret it correctly.

Incorrect model orientation

In 3D printing technology, it is important to properly align the part on the printer’s working platform. Improper orientation of the model can lead to deformation, an increase in the number of supports needed, or deterioration of the print surface quality, among other things.

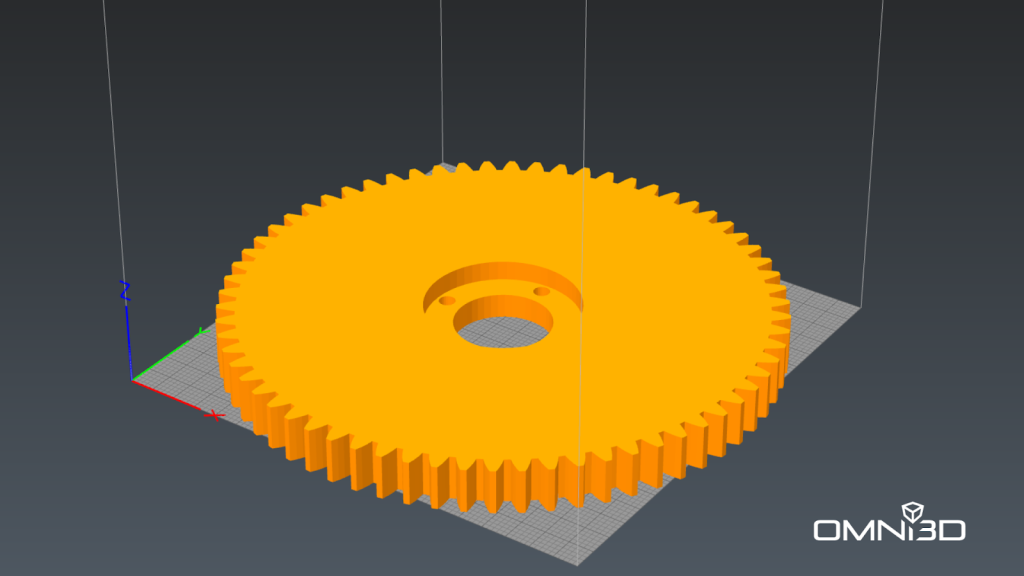

Model size too large

The item must have dimensions that fit within the printer’s working space. In case you want to make a printout of a larger size, you should divide it as much as possible into smaller parts and print them separately.

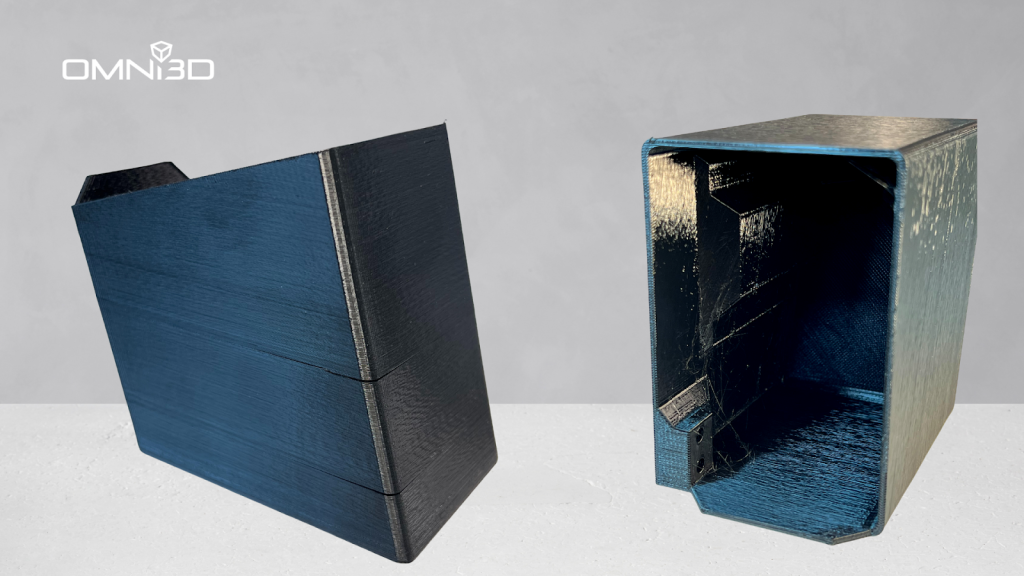

Inappropriate material

The choice of material is crucial to achieve a durable and quality print. Each material has different properties, so you need to properly prepare the process parameters before you start printing a specific part. For example, if you start printing an ABS part with printer settings optimized for PLA then the print will start to separate between layers.

Lack of proper software support

Preparing a 3D model for printing requires the use of appropriate software. Incompetent use of software or inexperience with it can lead to serious printing problems. It is also worth paying attention to the file format, which may not be supported with the software. In this case, it is necessary to convert the file to a compatible format.

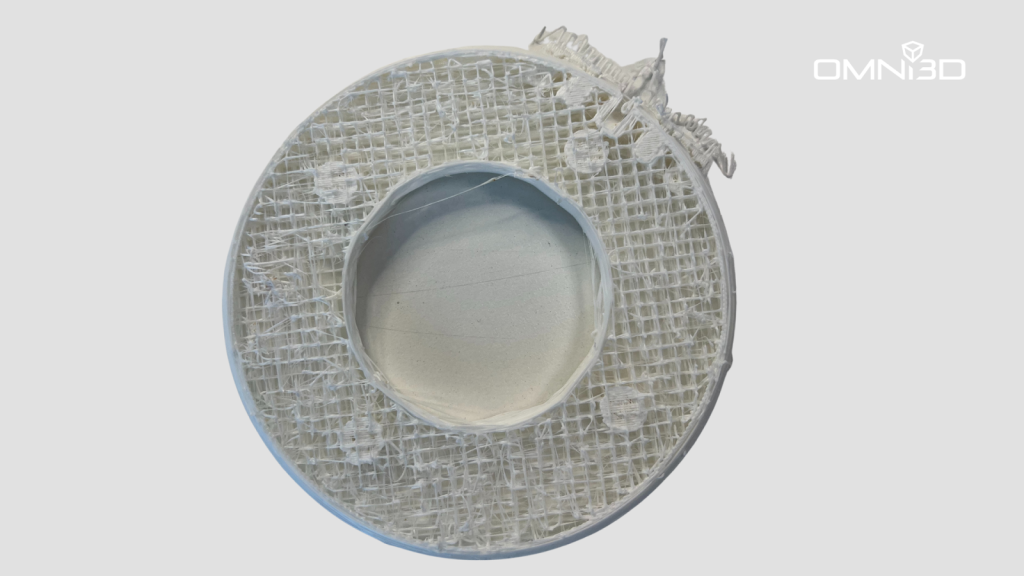

Improper process settings

Before printing a 3D model, it is necessary to set printing parameters correctly, such as layer thickness, printing speed and fill densities. An improperly prepared printing process will result in an unsuccessful print. This can lead to distortion, reduced strength, or poor surface quality of printed models, among other things.

Below is an example of a print with a poorly chosen extrusion ratio.

Stability issues

For more complex 3D models, it is often necessary to use additional support material. . It is used to make additional structures on which the printer can continue printing. Without it, the printed paths could not connect well together.

Summary

Preparing a 3D model for printing can involve some problems, which can usually be solved by using the right techniques and tools. It is important to conduct an evaluation of the process, paying attention to the above problems and their causes, in order to avoid unpleasant surprises during printing.

Contact:

LinkedIn Wojciech Wiśniewski

e-mail: wwis@omni3d.net