Reference printing – what is it and when is it used?

How do we find out about the capabilities of a printer before buying it? How to verify whether it will actually provide us with a printout in line with our expectations and technological needs? With help comes the reference printing service.

What is a reference printout?

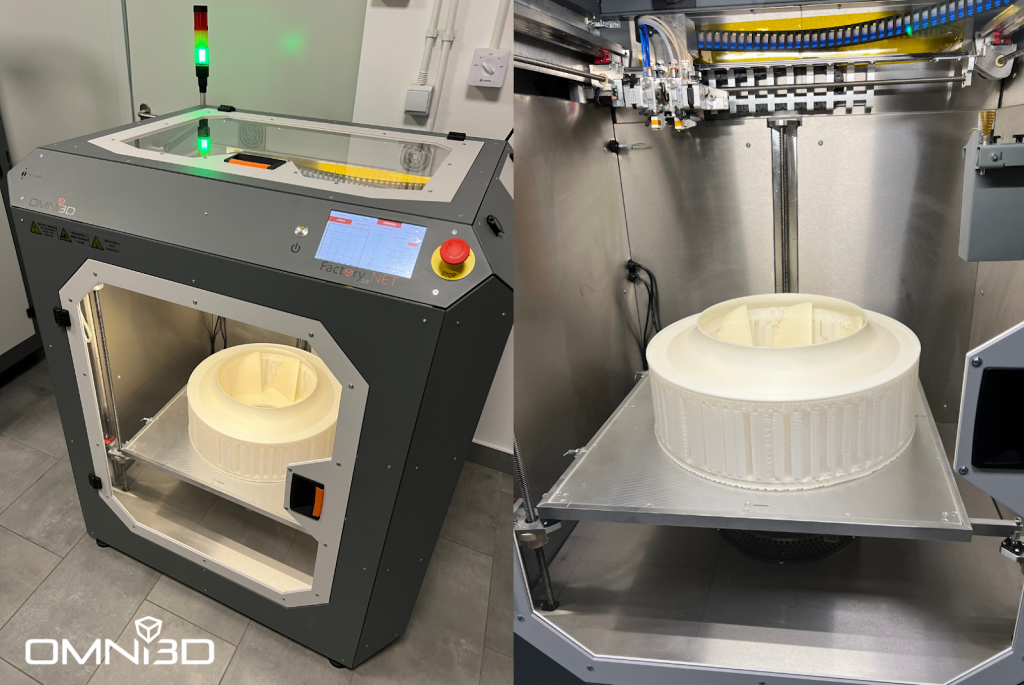

Reference printing is a popular method of verifying the quality of a 3D printer before purchasing it. The customer can see for himself on his own model whether the printing characteristics offered by the manufacturer are actually confirmed.

For whom is it targeted?

We recommend the print to all customers who want to test a 3D printer before buying it, compare the print quality with other 3D prints, or verify a 3D print with its authentic counterpart.

Benefits of reference printing

The realization of a specific print allows you to determine the time needed and the cost of producing it, which will help estimate the return on investment. This facilitates the decision as to whether to purchase a 3D printer.

On the basis of a reference model, the customer is able to verify whether the component has the necessary dimensional and strength accuracy. He can also check the ergonomics of the model and see if the printed part is identical to the real one.

In a situation where the customer is not sure about the choice of the technology for manufacturing components for the needs of his business, the trial print allows comparing products obtained by different methods and testing them.

Reference printing at Omni3D

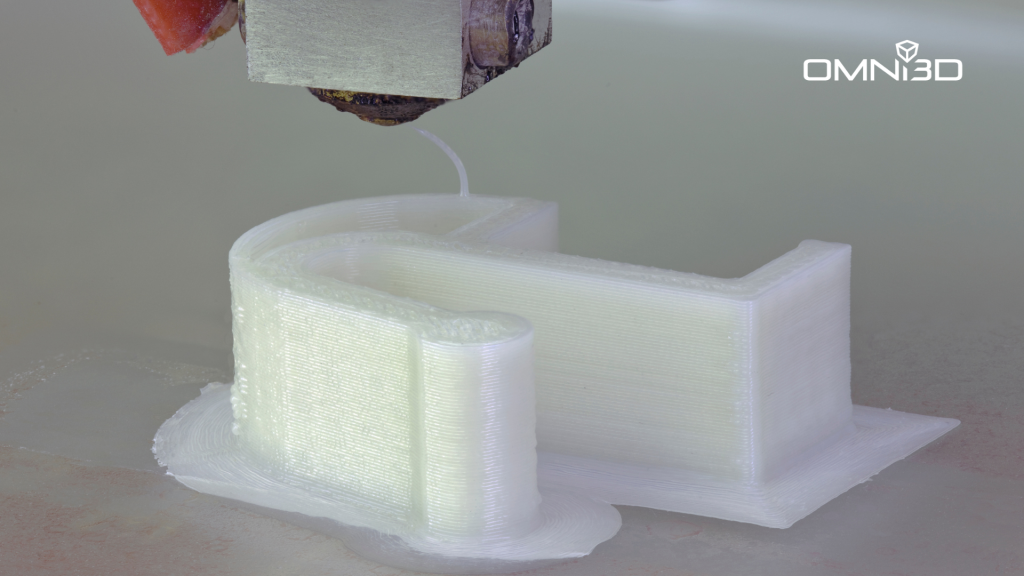

By performing reference printing in Omni3D, the customer has the ability to compare the relationship of quality and printing time against different head settings, such as 0.4 mm vs. 0.8 mm.

The ability to print the same model from different filaments allows us to show the differences in material properties, i.e. strength, finish, flexibility or temperature resistance. Filaments such as CF PA-12, TPU, PEKK, PPS or PLA differ significantly in their properties, so we can match prints to a variety of needs. The 3D printing technologist, knowing the customer’s requirements, will select the appropriate filament and printing parameters. Receiving a finished 3D print, the customer can test it, so it will be easier to make decisions on the purchase of the machine.

Setting various printing parameters provides an opportunity to demonstrate the capabilities of the Omni3D slicer. Using a concrete example, the printer’s ability to connect bridges or print overhangs and surface finishes can be demonstrated. Very quickly, we can show several iterations, i.e. make models with different print parameter settings, so we can illustrate that the user of the printer has an impact on the speed of the print, its weight, quality and strength, and thus the cost of its production.

If you are thinking about implementing 3D printing technology in your company – write to us – our experts will be happy to share their knowledge and advise you in choosing the right solution.