How to improve FFF 3D print quality?

The quality of a 3D printout is the most important parameter that often determines the use of 3D printing technology to produce a planned component. How to increase the quality of prints in FFF technology? Certainly, we need to pay attention to two key elements: the 3D printer on which we are working and the quality of the filament that we want to use for the project.

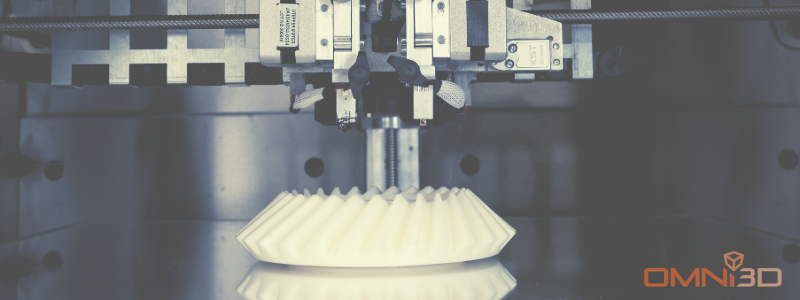

3D printing in FFF technology

FFF (Fused Filament Fabrication) technology, also known as FDM (Fused Deposition Modeling), is a versatile 3D printing technique characterized by the extrusion of a thick string material – filament from the print heads. Ease of use, optimal cost of implementation and durability of prints make this 3D printing technology very popular in industrial applications. We wrote more about this topic in the article „What is 3D printing with FFF technology?”

3D printer type and 3D print quality

Industrial 3D printers printing in FFF technology produce components with high accuracy (with error tolerance of up to 0.15%). Such devices allow greater control of parameters during printing and, as a result, a better quality of the printed component.

- The heated chamber plays a key role in industrial 3D printers. It minimises the effects of rapid cooling of the molten plastic, and allows materials with a higher melting point to be used.

- Most industrial 3D printers are equipped with a dual extruder which, thanks to the ability to use dedicated support material, makes it easier to print complex shapes and achieve a smoother surface.

- Industrial printers have a stable, metal construction, but also use components and solutions from the best manufacturers. These elements significantly influence the dimensional repeatability of printouts and guarantee constant, high quality 3D printing.

Watch the video: How to improve print quality in FFF technology? – answers Michał Kowalczyk, Sales Manager Omni3D: (with subtitles in English):

Kontakt:

m. +48 535 622 101

e-mail: mk@omni3d.com