Category: 3D Printers - USP, 07.01.2022

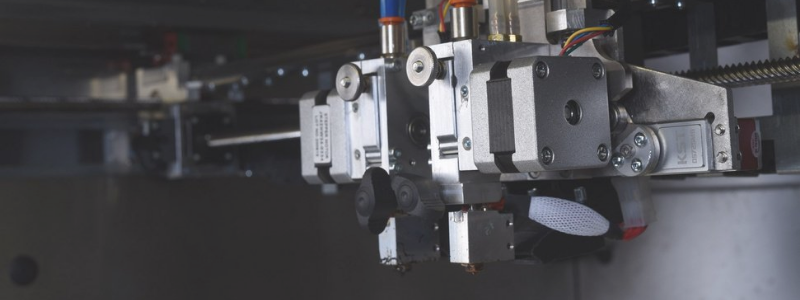

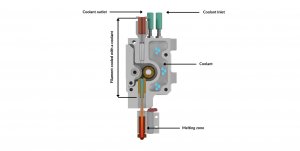

Omni3D Cooling System™

The Omni3D Cooling System enables the use of the extruder in a heated chamber and provides better control over the dimensional precision of the printout.

The main assumptions of the system are:

- The extruder direct cooling system, which effectively reduces the temperature inside the filament „path” by 40 – 60 ° C. This prevents the filament from reaching the softening point (called Deflaction Point), increasing its stiffness, which affects its control, increases printing speed and process stability over long periods.

- The special construction of the extruder allows to shorten the path between the filament feeding wheel and the nozzle, ensuring more precise feeding of the filament to the softening zone.

The use of this patented technology of direct extruder cooling allowed users of Omni3D printers to print at a higher level of accuracy and gave them the ability to precisely control the amount of filament that is extruded during printing.

Find out more about Omni3D Unique Points:

Powiązane artykuły