Omni3D patented solution – US 2019/0184633 Al – 1st patent in the USA – that describe the reason of having Omni3D Printer

In today's world of 3D printing, there are still many areas that require further research. Every month we hear about new solutions. Almost every manufacturer can boast of functionalities that give them an advantage. In Omni3D, from the beginning, we followed the path that was to give us the feeling of the best possible control over the printing process, stabilization of the basic conditions, in terms of the filament temperature, the speed of its feeding, "holding" on the feeding gear and possible flow control. As a result, we can introduce one of the most important implementations related to extruders.

The entire patent is described under the number US2019 / 018633 A1 in the USA, Europe and Poland under the number EU / PL: 230139 (PL230139B1)

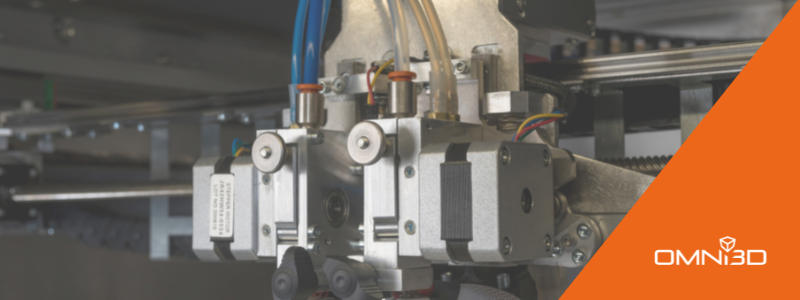

The purpose of this solution was to introduce an extruder system together with a printing head and an assembly system that could be used in the 3D printing process – in the FDM / FFF technology. The system provides greater control over the temperature of the supplied filament and significantly affects the quality (exact) of the temperature control of the printing head.

The main task for me, as the designer of this solution, was to improve the working conditions for the knurled-filament-filament clamp system. These elements had to work at a sufficiently low temperature to ensure the right force for pressing the filament into the heated head. To improve these parameters, we used a cooling system that receives thermal energy from the extruder body, transmits energy through the liquid pipes to the cooler, which „ejects” excess heat energy to the environment, and thus improves the operating conditions of the previously mentioned system. Thanks to the use of such a solution, it was also possible to stabilize the operating parameters of the extruder motor and it made it possible to resign from the head heat sink. In this case, the heat sink function was taken over by the extruder body. Thanks to this, the extruder became compact, and at the same time allowed for printing for many hours in a heated printing chamber – Piotr Maslej, Senior Constructor and Patent Inventor in Omni3D

The aim was therefore to design the extruder in such a way that it was possible to directly cool the element feeding the filament to the head and the filament itself, under the conditions of increased temperature of the heated chamber. In other words, the task of this system was to reduce the temperature of the filament as much as possible on the path leading to the liquefaction zone – so as to minimize / eliminate the risk of softening at the wrong stage, i.e. in front of the printing nozzle. Cooling also significantly affects the operation of the stepper motor, which, by lowering the temperature, minimizes the risk of, for example, lost steps.

The head cooling system provides to the users of printers from Omni3D the possibility of maximizing control over the printing process, in the sense of controlling the quantity and stability of the fed filament.

The stable operation of electromechanical components at higher temperatures of the environment is one of the major challenges faced by designers of current 3D printers. The use of the described patent allows for stable operation of the extruder motor without the need to use heat sinks to remove heat from its body. By eliminating heat sinks, the head weight of the device is reduced, which in turn enables printing with greater acceleration and maximum speed. Effective heat dissipation from the body of the stepper motor also reduces the risk of losing steps, and thus the loss of the motor shaft position, which can always occur in drive systems with an open feedback loop. Another advantage of the described solution is the ability to quickly replace the print head. Changing the head is intuitive, fast and does not require specialist knowledge from the printer User. Mounting the head through a thin-walled connector prevents heat from getting into the elements above the heating block that should not be heated. As a result, the heater power is consumed only for heating the heating block and there is no energy loss – Piotr Nawrocki, R&D Manager

Another solution that was included in the described patent was the modular head assembly system. This was to make it as easy as possible to change the heads and minimize errors that could affect printing.

Replacing the heads in Omni3D, consistent with the patent, provides the user with safety and thanks to its functionality, much greater reliability and certainty that the heads will always be installed correctly. This is necessary for the proper use of the double print head, which allows us to print from 2 types of filaments (base and support) at the same time.

The use of a double head system thus determines and explains the importance of the patented Omni3D solution, which provides:

- stable and equal base conditions

- constant low filament temperature on the element feeding the filament to the head and in front of the head itself

- increasing the controllability of the process, wherein the 2 filaments may have different softening temperature parameters

- gives the user a much greater sense of control and increases process stability

Many users tell us: „Omni3D printers are the only ones that give the feeling that what we have designed on the computer will actually be printed, and additionally every parameter that we change in the software (slicer) will be visible on the printout”. This level of „feel” is the most important for everyone who knows about 3D printing, because it allows you to minimize costs, time, and ensures safety and unparalleled repeatability of prints.

The patented Omni3D solution enables better control of the amount of filament fed, and thus increases the accuracy of the printed elements. Thanks to this solution, it was possible to implement filament flow control sensors, which in a continuous system compare the amount of filament fed with that set in the gcode.

The whole solution makes Omni3D printers often the choice of those who want to provide themselves with the final solution from the very first print, and thus increase their competitive advantage … by printing faster, more reliably thinks and minimizing unnecessary costs in the same time.

Here you can find more information about Omni3D Cooling System™ oraz Omni3D Filament Flow Control™

patent EU/PL: 230139

patent USA: US 2019/0184633 A1

* lost steps in 3D printing – Shifting the position of the head or table most often caused by the inability to perform rotation by the stepper motor driving the axis. For example, due to a collision or drag on the axle.