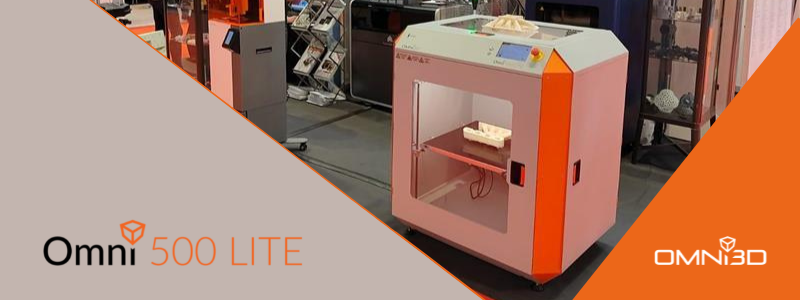

Omni500 LITE – new version for 2022 – the answer to the needs of users

The first items of the Omni500 LITE printer left the production line in 2020. The idea of this device was to provide to our customers the possibility of 3D printing large objects and working with basic and engineering materials. As a product dedicated to customers who wanted to implement a professional 3D printer at a reasonable cost, Omni500 LITE was characterized and still is characterized by a stable structure, advanced electronics and components, the open and wide access of spare parts in every corner of the globe, makes it a product ensuring stable, safe operation and quick solving of arising difficulties, no matter how far the manufacturer or its warehouse, or service is located.

In 2022, listening to the opinions of our partners and customers, we decided to renew the printer and introduce changes that would adapt to the growing market needs. Users who already have experience with Omni500 LITE and have learned to work with it asked to add a few elements that will allow them to use the full capabilities of the device and at the same time increase the sophistication of their prints. “The school” provided by Omni500 LITE is something wonderful and makes you want to break new barriers in industrial 3D printing

Omni3D Head Leveling Control™- now on the Omni500 LITE

The new version of the Omni500 LITE is primarily an inactive head lifting system. In this case, we decided to introduce a system that raises / lowers the right extruder. This system is already known from the Factory 2.0 and Factory 2.0 NET printers, and in the case of the Omni500 LITE it has been simplified and adapted to the existing equipment.

The introduction of the inactive head lifting system ensures:

- the ability to work with more geometrically complex designs. There is no risk of damage or touching our 3D print by an inactive head.

- this system also enables the automation of the head calibration process – and thus directly translates into the ease of use of the Omni’s printer

- significantly increases the level of repeatability of prints

What’s more, an additional advantage is the possibility of using a new Z axis leveling system, which now directly tests the distance of the heads from the working surface, making the measurement more precise.

NEW – Build platform in a 3D printer – more opportunities for users

In 2022, we also decided to change the building platform – a new aluminum structure, milled on both sides, means the highest surface flatness for users – which for a printer gives a chance to increase the level of printing precision which is a key element of the work.

The glass buils platform has also been modified, its mounting and the mounting of the platform itself. As a result, users of Omni500 LITE gained:

- print security for large items

- a system of new glass holders protects against „surface floating” and minimizes the effect of vibrations that arise during the printing process

- the new platform mount compensates for the negative effects of thermal expansion – ensuring surface stability throughout the printing time.

The new version of the Omni500 LITE printer expands the machine management capability, adding new functions supported not only from the LCD level, but also from a dedicated website. This is the next step to facilitate the operation of the printer and thus 3D printing is becoming more and more available. The use of modern engines in combination with modern drivers, the quality, work culture, and accuracy of prints are at the highest industrial level. The machine has a great potential for development, it is the result of the work of each R&D department and every day, and with each printout, it is used in various industries – Dawid Wojtas, Head of the R&D Omni3d Programmers Department

Construction of a 3D printer from Omni3D

The new aluminum construction affects the uniformity of temperature distribution, safe heating of the table, and also ensures stable conditions in the traction of printing. The last change – but also a very important one, is the newly designed cooling system of the head heatsink. This gives the user:

- improving the temperature stability of the heads, thus stabilizing the outflow of the filament

All the changes that we have introduced are a response to the needs of users who have noticed that the Omni500 LITE is a device that can do much more than in the original assumptions. The 2022 version was created thanks to customers who demand the highest possible quality from a 3D printer.

Importantly: current users of the Omni500 LITE printer can partially change – updrade – used printers, so that they can be retrofitted with an inactive head lifting system.

The new software and a chance of implemen Omni3D Head Leveling Control™, for the first versions of our Omni500 LITE, will ensure that you can make the most of the new possibilities.

More information from our Partners and directly from Customer Support Omni3D service@omni3d.net or mn@omni3d.net