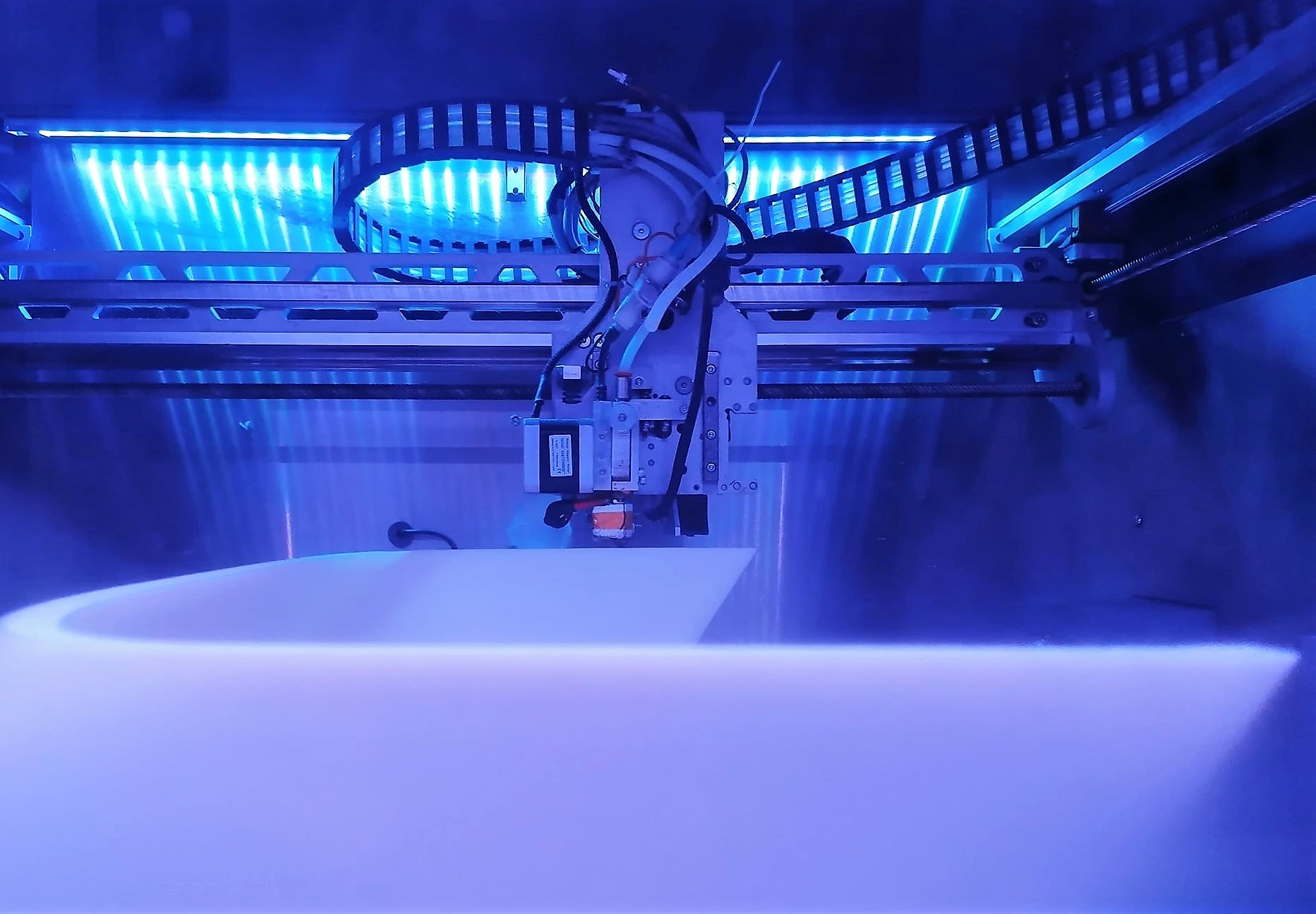

3D printing on demand – the benefits of cooperation.

The purchase of an industrial 3D printer is just one of the options offered on the additive technology market. An industrial 3D printer can be rented or leased. Another solution is the 3D printing service on request.

Is it profitable to outsource 3D printing to an external company? According to the Sculpteo 2020 report (The State of 3D printing), over 60% of companies using 3D printing notice a significant cost reduction of producing one part using 3D printing. Let’s take a closer look at the benefits of a 3D printing on demand:

Time and cost savings by implementing 3D printing

3D printing supports the proper handling of resources within the company. By implementing 3D printing in such a form, the company receives access to spare parts or frequently worn-out machine elements and production lines – in unlimited quantities and exactly when needed without unnecessary storage and freezing of resources. Printing a specific part in 3D takes several hours. The result? Reduced downtime during the implementation of individual projects and the delays that result from waiting for the necessary tools and parts.

The 3D printing on demand is a great way to gain a competitive advantage when we don’t have the right equipment and investment budget. What’s more, this way we can also save costs associated with the need to train employees on 3D materials and technology. We test new materials and projects without worry – because 3D printing can save up to 90% of costs and 80% of time!

Knowledge and technology in 3D printing

Without a doubt, 3D printing has become a significant competitive advantage. 3D printing technology opens up new opportunities for prototyping, spare parts and final parts – from the automotive, medical and aerospace industries to architecture and industrial design. It allows you to create the most complex models and complete difficult projects much faster than traditional methods – so it’s no wonder that more and more companies are implementing 3D printing technology permanently into their production.

3D printing on request gives us a wide range of material possibilities. Individual parts can be tested from different materials (filaments) and new solutions, ideas and technological projects can be tested much faster. Since 3D printing is a more economical form of production (material waste is minimal), you should not be afraid to print several versions of the model and test how such elements work in real conditions. The applications of industrial 3D printers are really wide and easy to implement in the form of a 3D printing on demand.

Cooperation in 3D printing on demand

Buying your own 3D printer has the obvious advantage of retaining all the knowledge and know-how associated with printed projects inside the company. However, 3D printing on demand is an ideal option to implementing 3D technology in your company.

How to make a decision on the proper implementation of 3D printing in your company? You should start by contacting experienced 3D printing specialists, who will help you choose not only the right printing technology, but also the best materials that will work in the production process. Remember that you can always get an estimate of the price of the printed element.

Summarizing, according to the already mentioned Sculpteo 2020 report (The State of 3D printing), over 50% of the respondents admitted that in the coming years 3D printing will play a significant role in production and business. So consider working with 3D printing in your company – ask our specialist and find out more about the possibilities offered by industrial 3D printing.