ABS material advantages

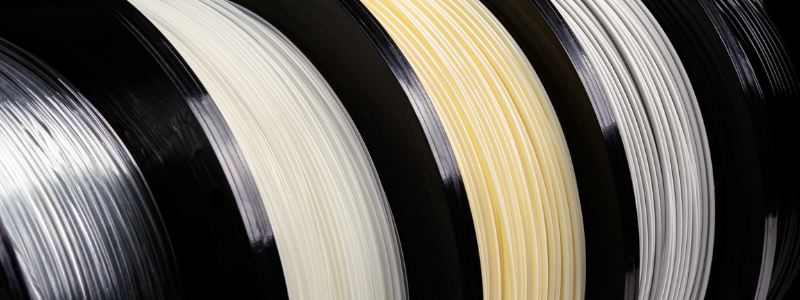

Until now, ABS has mainly been used in injection molding, but has also become one of the most popular materials for additive printing. Why has this happened? It is primarily a material that is characterized by very good durability in relation to the price. It is a hard, stiff material, resistant to scratches and dents, and it works well in the environment of oils, greases, fats and selected acids. In addition, it is prone to dyeing, therefore the filaments market is available in very different colors. Among the filaments for printing, You can also find reinforced ABS variants, i.e. PC-ABS, which has a higher temperature resistance than a standard ABS, and has an impact resistance similar to PC.

ABS temperature resistance

The popular ABS, like any other material, has its advantages, but also disadvantages. As a one of disadvantages ABS is relatively low temperature resistance and very poor resistance to UV radiation. When the printout is exposed to the sun for a long time, it turns yellow very quickly. If for someone this defect disqualifies this material, then it is worth considering the ASA-39 material, which is resistant to UV radiation. High resistance to high temperature allows You to test printouts in direct sunlight without the risk of discoloration or deformation.

How to print from ABS?

The ABS-42 filament offers many possibilities, but not every printer is able to print from this filament. In order to be able to print ABS, the absolute minimum is a closed chamber of printing and a working table that is able to heat up to at least 70 ° C. However, as for the extrusion temperature, it should not be lower than 230 ° C. In a situation where we plan to create large, repeatable ABS prints, it is worth investing in an industrial printing solution that will guarantee a higher temperature in the chamber thanks to an active heated chamber. This is very important from the point of view of controlling material shrinkage, which can throw many printers off balance on lower-class equipment.

The ABS-42 filament is supported by the industrial series of 3D printers from Omni3D:

Factory 2.0, Factory 2.0 NET, Omni500 LITE.

and OmniSTART, Omni200 and Omni200 (CF) desktop printers.

Contact:

m. +48 535 622 101

e-mail: mk@omni3d.com