Application of 3D printing in architecture

The use of 3D printers in architecture and construction is increasing, and already many architects and designers are convinced that the implementation of 3D printing on a wider scale will be a real revolution. Creating functional final elements - decoration, furniture and gadgets are just a fragment of the possibilities offered by 3D printing technology. Discover examples of 3D printing applications in architecture!

3D printing technology in the construction industry is valued for its speed of realization – printed parts are created incomparably faster than those produced traditionally, for example in metal. In addition, printed forms provide greater flexibility for architects to incorporate unusual shapes and design solutions into their projects.

3D printing in the construction industry

Printing a few or several hundred pieces of a specified element may be more beneficial than ordering individual production. Moreover, 3D printing gives us the possibility to manufacture products with complex geometry, using a wide range of colors. Dedicated materials for this industry are ABS, CF-PA, or PVC. Why is it worth considering 3D printing in the construction industry?

Advantages of 3D printing

- Production of the number of elements according to the demand and needs of the customer

- Possibility of making changes in the model

- Quick, creative and individual approach to the product

- Low cost of manufacturing any amount of elements

- Reduction of costs in the tooling sector

- Flexibility of tool design

Examples of 3D printing applications in architecture

A 3D printed sanding block is the first example of a desktop 3D printer being used in the construction industry.

A tool specially designed to work with sandpaper was printed on our OmniSTART desktop printer using ABS-42 filament

INEX System company asked Omni3D to print 15 thousand elements used in furniture production. 3D printing turned out to be the cheapest and the fastest method of production of the specified parts – in comparison to traditional production, our Client saved time (production ended 21 days earlier), and production costs were reduced by as much as 79%! Series production was realized on two models of desktop 3D printers – OmniSTART and Omni200 using PET-G filament. You can read the full case-study here.

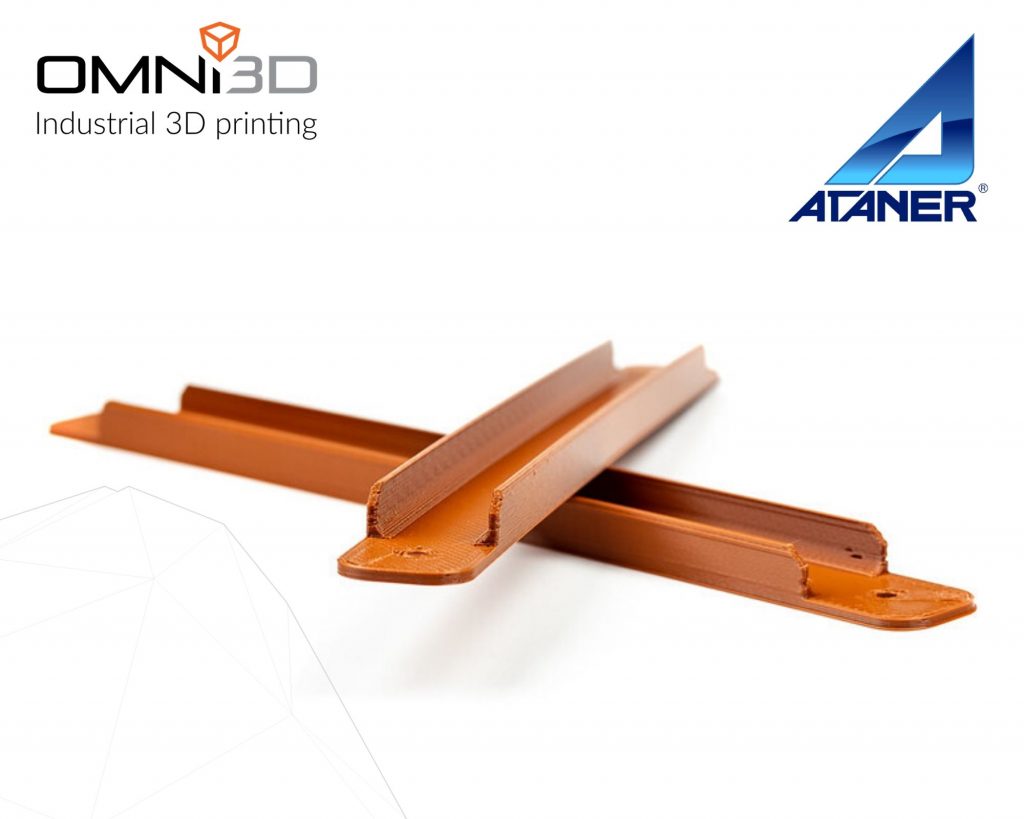

ATANER, a developer from Poznań, focusing on comfort and personalization, asked Omni3D to design a door end cap.

As a standard, in the apartments under construction, the entrance doors will be adapted for easy installation of a door closer. Thanks to this, the customer does not have to decide on such a specialized door when buying an apartment, but if he wanted to use such a functionality, the solution used was to enable him to do so. Full case-study of the project can be read here.

Want to know more about 3D printing?

Contact us and discover the possibilities of 3D printers