What will bring the 2021 in 3D printing?

Experienced by the difficult and unpredictable year of the pandemic, like every industry and segment, FDM technology is coming out of the corner. We have to find ourselves in this strange and new reality by finding new applications for 3D printing. What challenges lie ahead in 2021? The previous years have already directed the development of FDM and although 2020 has slowed it down a bit, the trends are still clear.

Author: Tomasz Garniec, Export Manager Omni3D

Customizing production with 3D printing

The previous years strengthened our belief that 3D printing, and in particular FDM / FFF, is an element used in prototyping and has already been classified as such. However, this is only the beginning of a long list of 3D printing applications. With the increase in the availability and functionality of 3D printers, more and more companies decide to introduce 3D printing as a production improvement. There are personalized special products and short production series on the market, where the 3D printing, and in particular FDM / FFF, has found its way perfectly. Low production costs, the ability to quickly change and adapt even individual elements to the manufactured product is what has been a trend for a long time. In 2021, the development of this functionality will be noticeable – companies increasingly want to adapt to customers, to their individual requirements, and at the same time seek to reduce costs and reduce the associated risk. Personalization is a word that will be repeated often in the context of 3D printing in 2021.

3D medicine in the fight against Covid19, but not only…

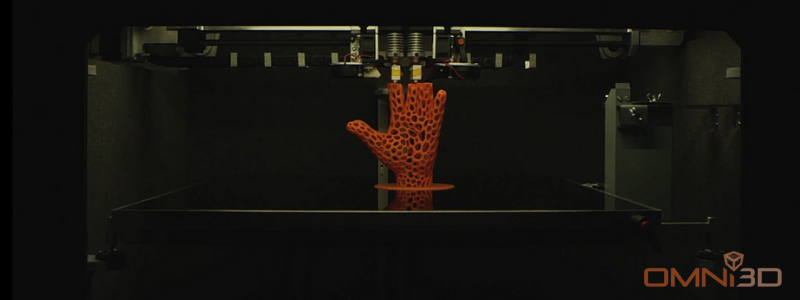

We often hear that 2020 was the year when 3D printing was rediscovered, and it’s hard to disagree. 3D printing gained popularity during the fight against Covid 19: face shileds, respirators made by 3D printer, face masks, Covids’ testers – all this showed that the greatest benefit of 3D printing is the ability to quickly adapt to a situation, which is often a decisive factor and live saving item in critical times. In 2021, it will be no different. The epidemic continues to cast a shadow over the economic future of many countries. 3D printing will be on the front lines, but not only that. Recently, more and more medical and rehabilitation units pay attention to the possibilities of 3D printing in order to more effectively respond to the changing reality. Increasingly, FDM / FFF printing is used in the production of stabilizers, orthoses, personalized drug dispensers, training models and spare parts used in hospitals or other medical-related units. What’s more, 3D printing in medicine is not only an area related to humans, but also veterinary medicine.

Body-neutral 3D printing – the future of FDM/FFF and medicine

One of the features of FDM / FFF printing is the rapidly expanding range of filaments. The largest chemical concerns, as well as individual research units, are looking for new applications and accelerate the development of filament types and blends. Bio-printing, which is mostly associated with printing cells, has recently been extended to include the possibility of using filaments. Biocompatible filaments, neutral for the body, will be a significant trend in 2021, but also in the following years. The materials are diverse in terms of characteristics and properties, which makes them an ideal material for use in this segment of medicine and related industries, and the universality of 3D printers will be a key challenge for manufacturers here.

- Rapid growth in 3D printing materials a driving force for 3D printer manufacturers

Increasing consumer awareness of the possibilities of using 3D printing and the trend to more unify production has become the driving force behind the creation of more specialized filaments. This is how PEEK – CF was created, which is the strongest material printed by FDM printers (which do not require additional processing). We are observing the rash of mixtures that respond to specific application needs: CFPA, ABS-PC, ABS-ESD, PETG-ESD and many others …

Material ranges meet the needs of specific, ever narrower groups of users and mean that the development of FDM / FFF printing is ahead of another year with a strong trend of dynamic development.

Someone might say – „cosmic!” and it will not be surprising, because the use of 3D printing in space is also nothing new.

I can certainly say that 2021 will be the time that will not run much faster, it will be by the pandemic that is all around, but it will be also the year in which companies will look for development opportunities and ensure security for themselves and their operations. 3D printing – and FDM / FFF in particular, will be a great source of inspiration and can help in the above processes. The development of materials and the development of printer manufacturers will undoubtedly provide a wide field for managing the current and future related needs. It will be an interesting year and I wish You success.

Want to know more about 3D printing?

Contact us and discover the possibilities of industrial 3D printers

Contact:

LinkedIn: Tomasz Garniec

m. +48 886 618 588

e-mail: tg@omni3d.com