3D printing in industry

There is no doubt that industry today is prepared to pay a premium price to engage in low-volume, customized or personalized manufacturing and to produce items that cannot be produced by traditional methods. Keep in mind that just a decade ago, no company in the industrial sector was using final parts made in whole or in part on a 3D printer in their manufacturing facility. It is therefore impressive that we are moving dynamically towards automation and robotization.

The advantages of 3D printing in the industrial sector

- Rapid prototyping

The wider industry is perhaps the best example of the use of incremental technology for prototyping. Design changes that would take much longer using conventional manufacturing methods can be implemented much faster, often in less than a week, using 3D printers and at a much lower cost.

- Shorter lead times

According to Sculpteo’s State of the Industry report: 52% of those in the industrial sector prefer 3D printing for its ability to reduce lead times and implementation. As the process does not require any tools, manufacturers can reduce the time it takes to produce parts. This is confirmed by the use of 3D printing in 3D printing in the furniture industry

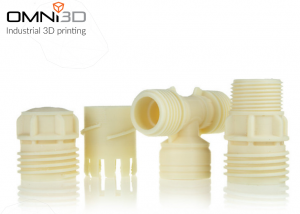

- Models with complex geometries

Industrial 3D printing is a cost-effective technology for producing parts with complex geometries. With 3D printers equipped with dual heads, we are able to realize projects that we previously thought impossible. 3D printing is a chance to create personalized elements, such as in the Volkswagen factory, parts for robots that cooperate with humans!

- Low-volume production

An industrial 3D printer with a large build volume can produce real parts from digital files in a few hours. On-demand production parts become an advantage for the company. Producing a batch of 100,200 or 500 parts is no longer a challenge. What’s more, by being able to get an estimate for 3D printing, we can quickly compare the cost of producing an item.

- Maintenance

Optimizing production processes reduces operating costs. An integrated system based on the specific use of the production line’s resources allows us to predict the load and failure-free operating time of components. Printing specific spare parts minimizes the risk related to production downtime. It is perfectly illustrated by our Luk-Plast case, 3D printing of a vacuum pump.

- Industrial 3D printing

The demands on the quality of the materials used are becoming ever higher. 3D printing technology is an answer to the actual needs of everyday businesses and a solution to optimize costs. The fact is that 3D printing is changing the manufacturing industry. It gives us the advantage of reducing costs and production time. So let’s analyze what features a 3D printer for industrial applications should have:

- large-format build volume (500x500x500)

- automatic machine calibration

- high temperature capabilities

- possibility of remote management

- 3D printer farm management

A 3D printer that meets the above requirements will be the right choice for customers who expect a higher standard of printer management and work with demanding materials.

Want to know more about implementing 3D printing technology in your company?

Contact us! Receive a free audit of using 3D printer in your company