ADDITIVE MANUFACTURING FOR AUTOMOTIVE INDUSTRY

Streamline Assembly & Enhance Aftermarket Services: Omni3D’s High-Strength, Precision Large-Format Printing for Customizable Automotive Parts, Tooling, and Efficient Supply Chain Solutions.

Accelerate Innovation with On-Demand Automotive Manufacturing

From lightweight structural components to complex tooling and on-demand spare parts, Omni3D’s large-format, heated chamber 3D printers deliver the reliability and precision required for critical aerospace applications. Our open material platform supports a wide range of aerospace-grade materials, enabling you to optimize designs and streamline production.

Partner to leading companies

Volkswagen is one of the world’s largest car manufacturers. Known for models like the Golf, Passat, and Tiguan, it emphasizes innovation, sustainability, and electric mobility while maintaining its reputation for quality and reliability.

Arrinera developed high-performance sports cars. It gained recognition with the Arrinera Hussarya, Poland’s first supercar, featuring aerodynamic design and advanced engineering for track and road performance.

PRz Racing is a student-led motorsport team from Rzeszów University of Technology in Poland. Competing in Formula Student events, the team designs, builds, and tests high-performance race cars, focusing on engineering excellence and automotive innovation.

Autoclima is an Italian company specializing in air conditioning systems for various vehicles, including industrial, refrigerated, and electric vehicles. With over 60 years of experience, it is part of the Indel B Group and is known for its innovative and efficient climate control solutions.

application cases

Adapter for cooling systems

Low Volume Manufacturing

Glue Dispenser

Jigs And Tooling

Parts for Racing Cars

FUNCTIONAL END-USE PARTS

3d printers for automotive

OmniPRO |

OmniTECH |

OmniLITE |

|

|---|---|---|---|

| Build size | 500 × 500 × 500 mm | 500 × 500 × 570 mm | 460 × 460 × 560 mm |

| MAX. HEAD TEMPERATURE | 500°C | 420°C | 360°C |

| Max Chamber temperature | 220 °C (ACTIVELY HEATED) | 70 °C (ACTIVELY HEATED) | 50 °C (PASSIVELY HEATED) |

| BUILT-IN FILAMENT DRYER | YES | NO | NO |

| Brochure | Download | Download | Download |

Materials

At Omni3D, we believe in the power of choice. Our open material systems allow you to explore a vast array of materials, tailored to your specific needs. From engineering-grade thermoplastics to specialty filaments, our printers are designed to handle it all.

Omni compatible materials include:

ABS

Car door handle prototype

ABS

Automotive part

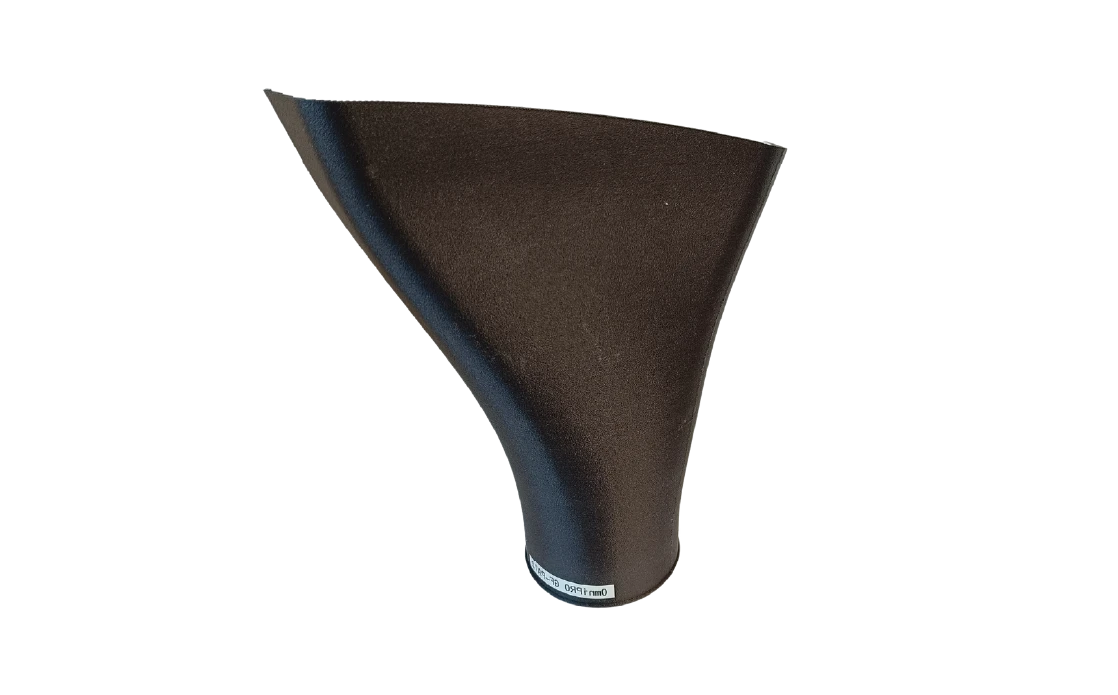

GF-PA12

Intake duct

TPU-93A

Joint covers

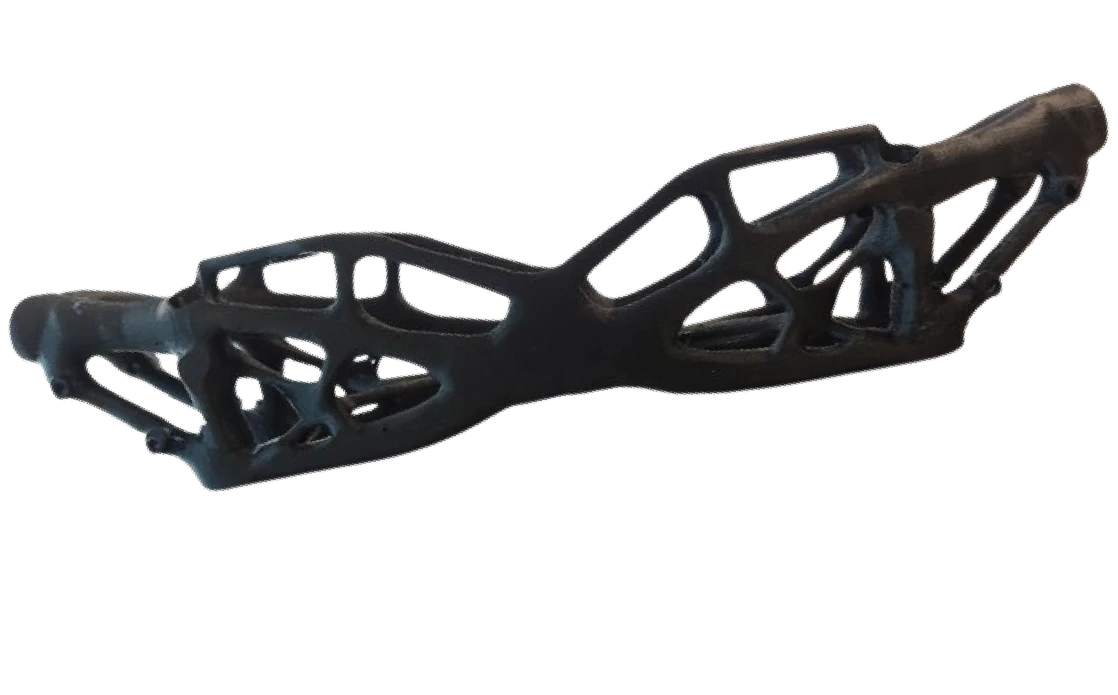

CF PA-12 + ODS20

Gear Mount

Industrial 3D printing solutions trusted by